| Availability: | |

|---|---|

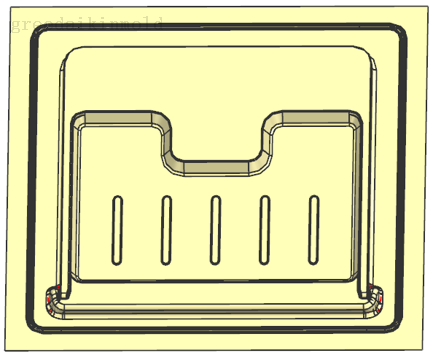

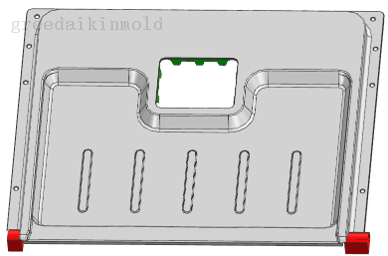

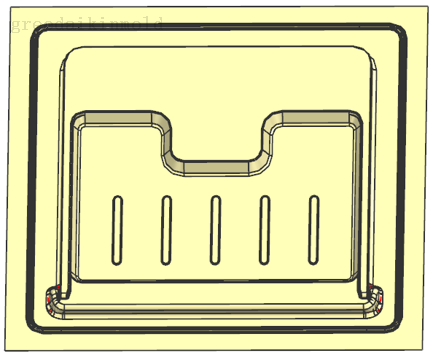

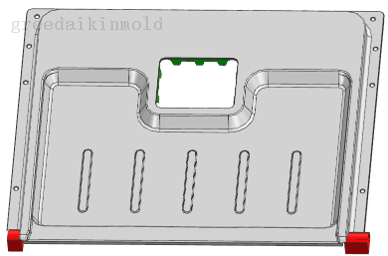

In the manufacturing process of dishwasher inner doors, the stamping dies can produce various styles and specifications to meet diverse market demands.

Dishwasher internal accessories syamping die

| Using full 3D modularization and precision standard library design |

| Stamping die parts use quick-change disassembly structure to facilitate cleaning and maintenance of internal components |

| Using integrated standard processing, parts can be used in multiple dies to ensure the service life of the die |

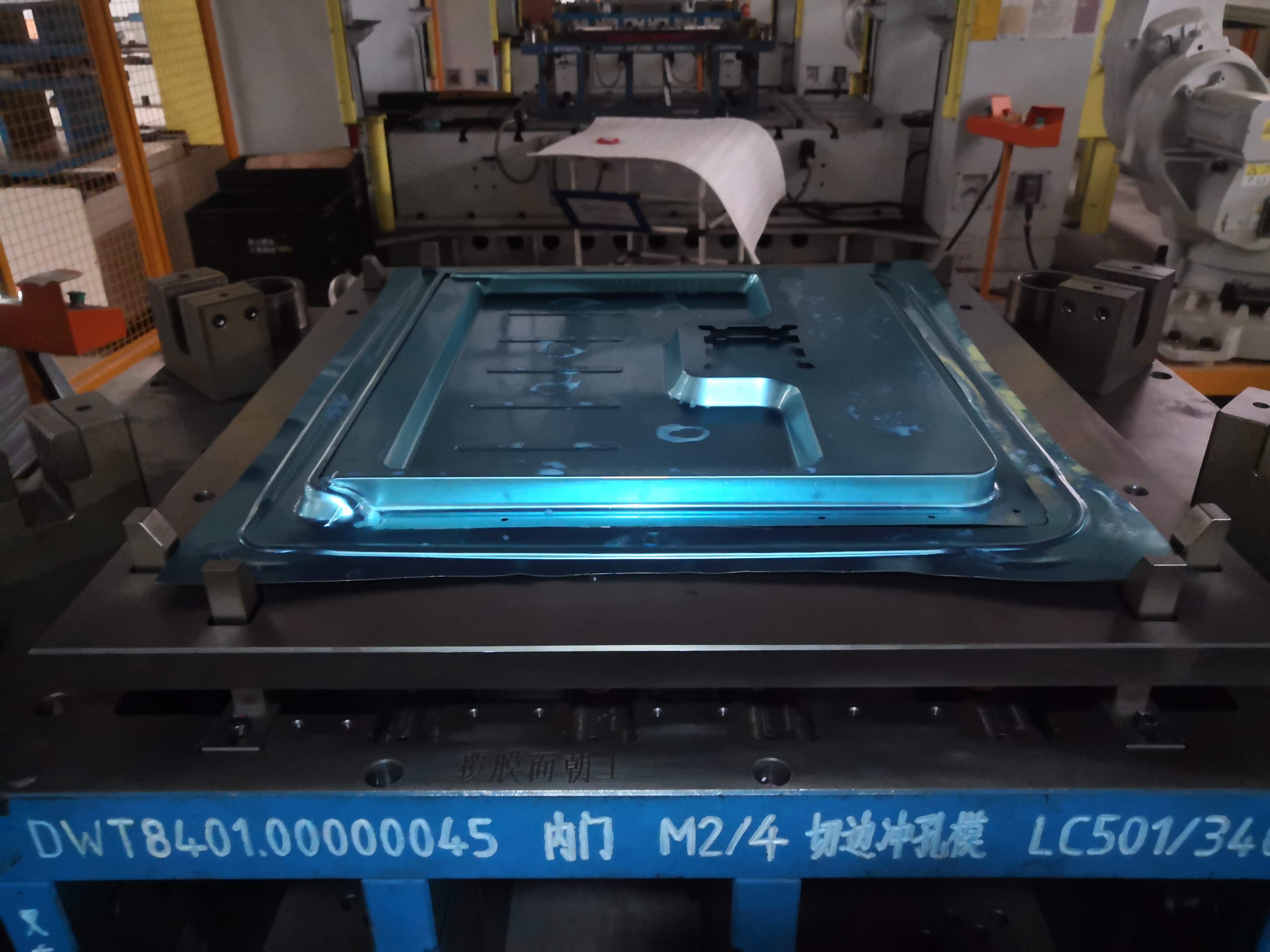

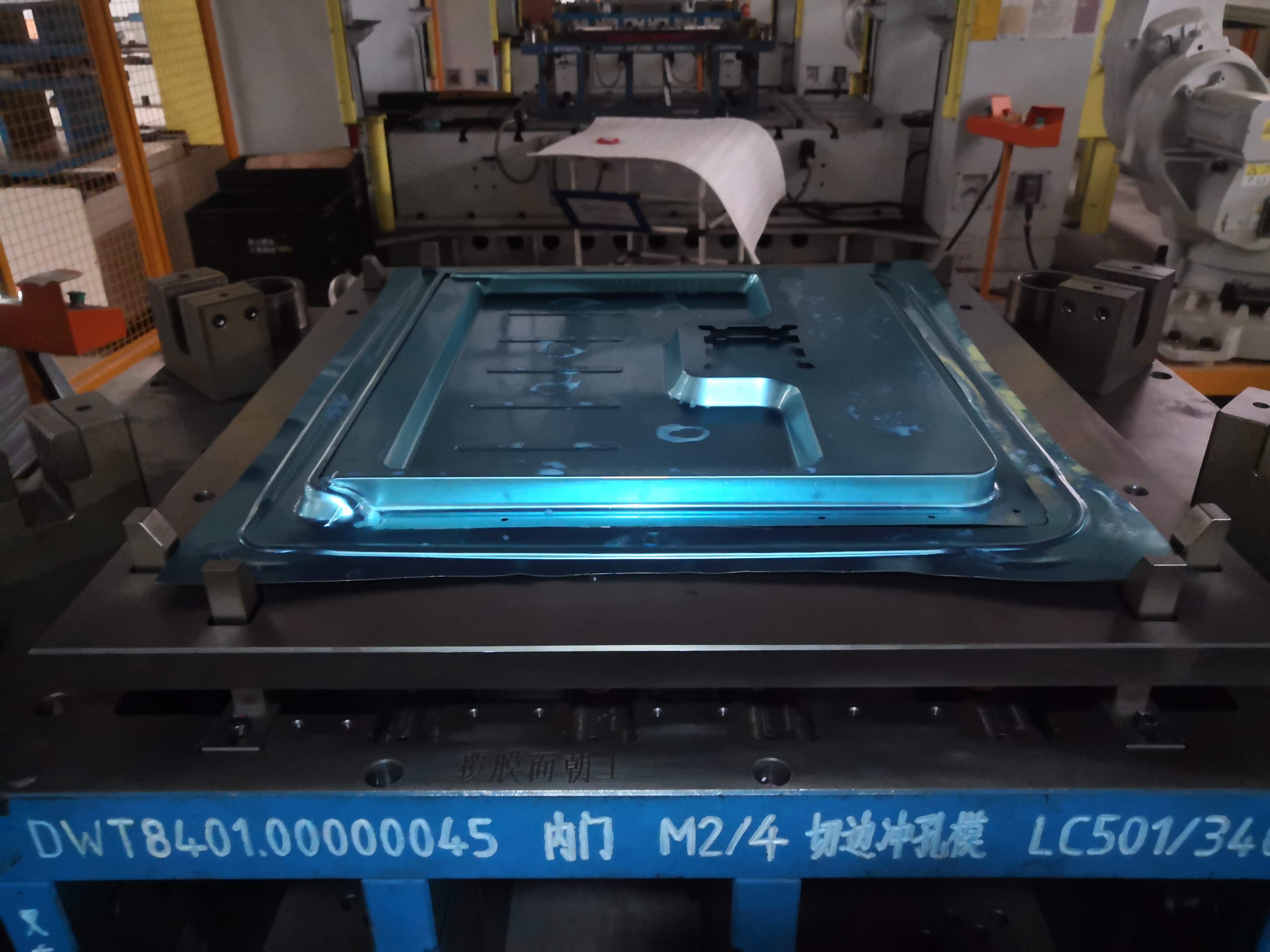

| Stamping die production is automatic line 4X400T punching machine robot production |

| Intelligent sensing die system |

| CAE algorithm predicts forming defects (accuracy > 95%) |

| Reduce secondary assembly process and increase the yield rate to 98.6% |

| Adopt nano-level CNC processing + EDM micro-hole technology |

GreeDaikinMold has 30 years of specialized experience in both stamping dies and injection molds to appliance manufacturing. We expertly produce dishwasher inner panel stamping dies while also offering custom injection molding solutions for exterior housings, providing complete end-to-end Mold & Die capabilities.

Our comprehensive expertise covers the entire appliance spectrum including kitchen equipment, home living products, entertainment electronics, environmental appliances, and personal care devices. As a dual-capability mold specialist, we ensure seamless integration between metal and plastic components for optimized appliance production. Contact us today for competitive quotes on your specific appliance mold requirements - from precision stamping dies to high-volume plastic injection molds.

In the manufacturing process of dishwasher inner doors, the stamping dies can produce various styles and specifications to meet diverse market demands.

Dishwasher internal accessories syamping die

| Using full 3D modularization and precision standard library design |

| Stamping die parts use quick-change disassembly structure to facilitate cleaning and maintenance of internal components |

| Using integrated standard processing, parts can be used in multiple dies to ensure the service life of the die |

| Stamping die production is automatic line 4X400T punching machine robot production |

| Intelligent sensing die system |

| CAE algorithm predicts forming defects (accuracy > 95%) |

| Reduce secondary assembly process and increase the yield rate to 98.6% |

| Adopt nano-level CNC processing + EDM micro-hole technology |

GreeDaikinMold has 30 years of specialized experience in both stamping dies and injection molds to appliance manufacturing. We expertly produce dishwasher inner panel stamping dies while also offering custom injection molding solutions for exterior housings, providing complete end-to-end Mold & Die capabilities.

Our comprehensive expertise covers the entire appliance spectrum including kitchen equipment, home living products, entertainment electronics, environmental appliances, and personal care devices. As a dual-capability mold specialist, we ensure seamless integration between metal and plastic components for optimized appliance production. Contact us today for competitive quotes on your specific appliance mold requirements - from precision stamping dies to high-volume plastic injection molds.

content is empty!

ZHUHAI GREE DAIKIN PRECISION MOLD CO., LTD.