| Availability: | |

|---|---|

Electrical enclosures serve as a critical foundational component in various electronic and electrical equipment, with safety as their core function. BMC material, renowned for its exceptional mechanical strength, superior heat resistance, and outstanding dimensional stability, along with excellent arc resistance and electrical insulation properties, makes it the preferred choice for manufacturing electrical enclosures.

The detailed information is as follows:

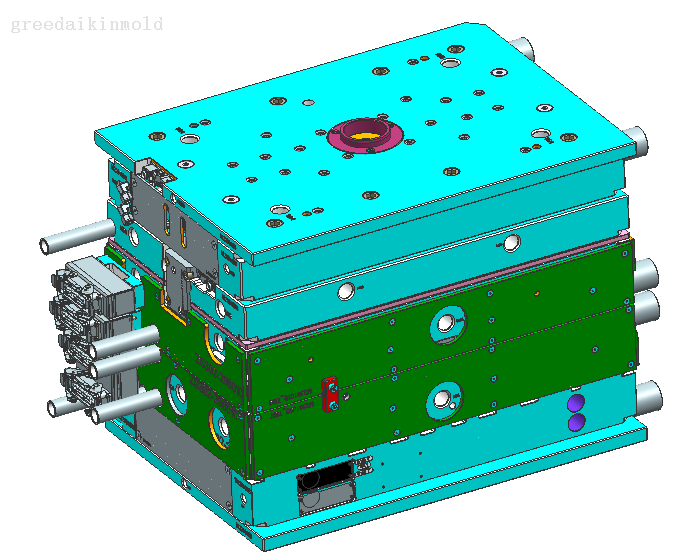

| Tool Material | 2344, S316 |

| Standard part | punch |

| Carvity Count | 1X1 |

| Injection molding machine tonnage | 360T |

| Mold Life | 300,000 times |

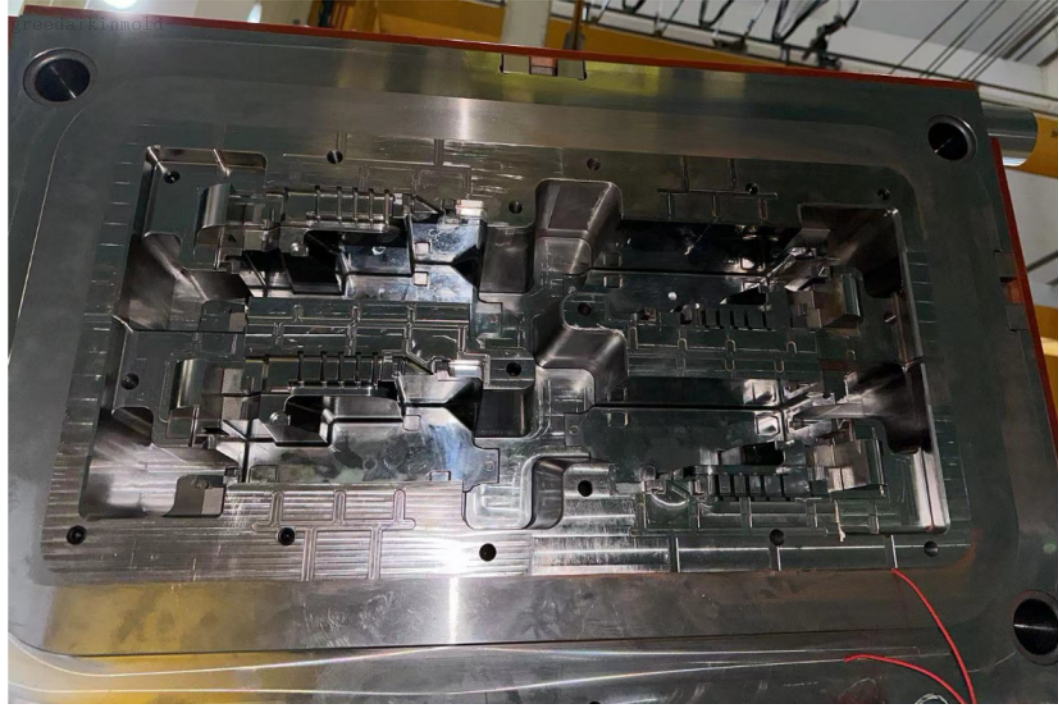

| 1. Single-Step Molding of Complex Geometries: Precision-tooled molds enable the production of sophisticated components, eliminating multiple assembly stages. |

| 2. Rapid-Cycle Automated Processing: BMC injection delivers fast curing cycles and seamless automation integration for mass production environments. |

| 3. Dimensional Stability & Surface Integrity: Finished parts demonstrate minimal shrinkage with resistance to cosmetic defects, facilitating secondary finishing operations. |

| We can achieve machining accuracy of up to 0.002 mm. |

| GDM's Proven 35 years of Expertise: Standardized BMC Solutions |

| Parts Consolidation and Lightweighting |

| Our technology utilizes CAE (Computer-Aided Engineering) to analyze the pre-deformation of products in advance. |

Electrical enclosures serve as a critical foundational component in various electronic and electrical equipment, with safety as their core function. BMC material, renowned for its exceptional mechanical strength, superior heat resistance, and outstanding dimensional stability, along with excellent arc resistance and electrical insulation properties, makes it the preferred choice for manufacturing electrical enclosures.

The detailed information is as follows:

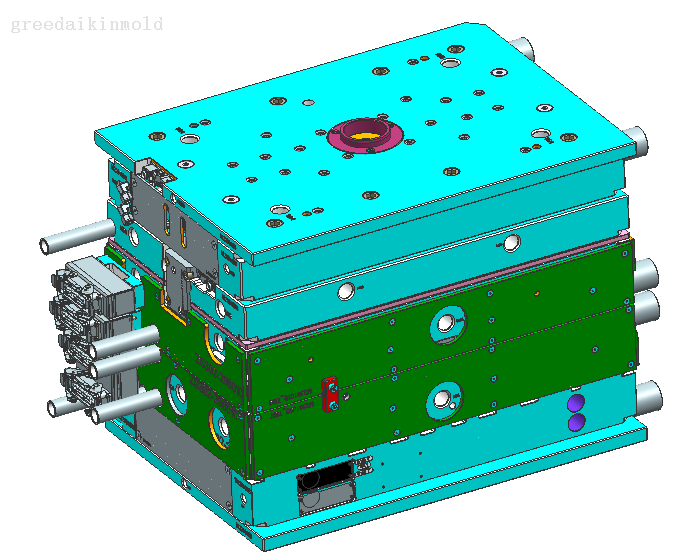

| Tool Material | 2344, S316 |

| Standard part | punch |

| Carvity Count | 1X1 |

| Injection molding machine tonnage | 360T |

| Mold Life | 300,000 times |

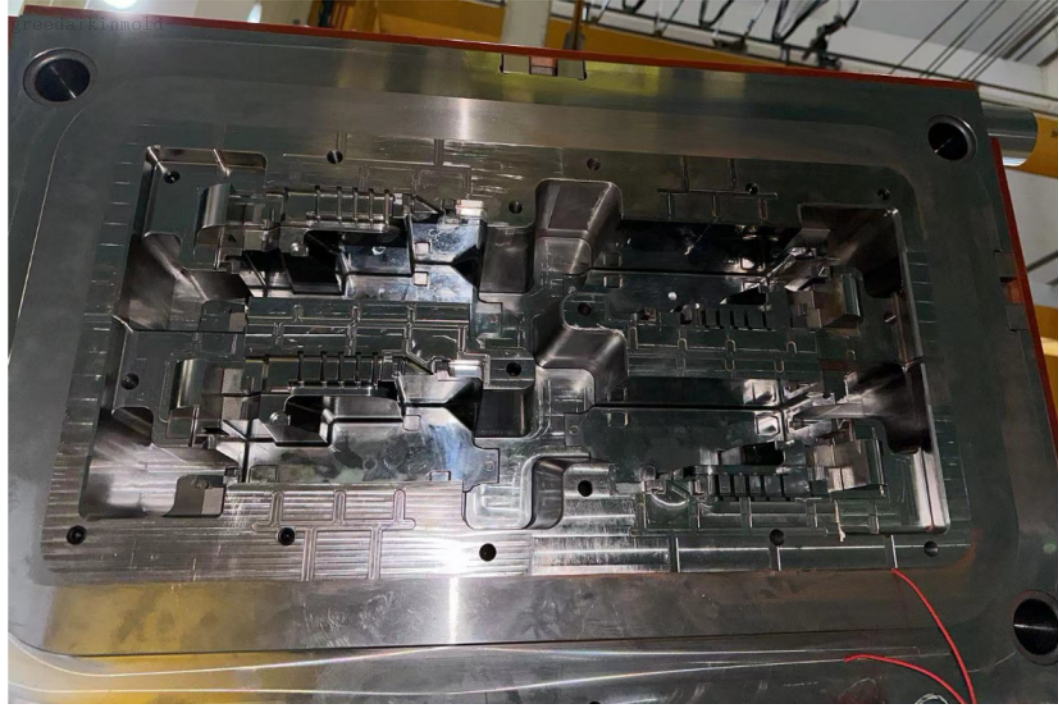

| 1. Single-Step Molding of Complex Geometries: Precision-tooled molds enable the production of sophisticated components, eliminating multiple assembly stages. |

| 2. Rapid-Cycle Automated Processing: BMC injection delivers fast curing cycles and seamless automation integration for mass production environments. |

| 3. Dimensional Stability & Surface Integrity: Finished parts demonstrate minimal shrinkage with resistance to cosmetic defects, facilitating secondary finishing operations. |

| We can achieve machining accuracy of up to 0.002 mm. |

| GDM's Proven 35 years of Expertise: Standardized BMC Solutions |

| Parts Consolidation and Lightweighting |

| Our technology utilizes CAE (Computer-Aided Engineering) to analyze the pre-deformation of products in advance. |

content is empty!

ZHUHAI GREE DAIKIN PRECISION MOLD CO., LTD.