Views: 0 Author: Site Editor Publish Time: 2025-07-29 Origin: Site

In the competitive home appliance industry, air conditioner manufacturers face increasing pressure to combine aesthetic excellence with durable performance. High-gloss, scratch-resistant panels have transitioned from premium features to consumer expectations, driving innovation in injection molding technologies. The pursuit of flawless surfaces represents a complex intersection of material science, precision tooling, and advanced manufacturing processes that can significantly impact product differentiation and brand perception.

The foundation for achieving flawless high-gloss surfaces on air conditioner panels lies in the integrated optimization of polymer materials, mold engineering, injection processing parameters, and surface treatment technologies.

This comprehensive approach addresses the persistent challenges of surface defects, including flow lines, sink marks, and microscratches that become magnified under gloss finishes. As industry standards evolve toward mirror-like finishes capable of withstanding harsh cleaning chemicals and abrasive environments, manufacturers must reevaluate traditional manufacturing protocols. The following analysis examines the technical roadmap for implementing high-gloss, scratch-resistant injection molding systems that meet both aesthetic benchmarks and functional requirements for modern air conditioning units.

The Critical Demand for High-Gloss Surfaces in Appliance Design

Material Selection Fundamentals for Scratch-Resistant Panels

Precision Mold Engineering Techniques for Flawless Finishes

Advanced Injection Molding Process Controls

Surface Enhancement Technologies for Maximum Durability

Comprehensive Quality Verification Methodologies

Innovations and Future Trajectories in Surface Technology

High-gloss surfaces have become essential in air conditioner panel design due to their ability to convey premium quality while meeting functional requirements for cleanability and environmental resistance.

Consumer psychology consistently associates high-gloss finishes with technological sophistication and luxury, driving manufacturers to prioritize surface excellence in appliance design. Beyond aesthetics, these surfaces present practical advantages in residential and commercial environments where frequent cleaning can degrade conventional finishes. The smooth, non-porous nature of properly engineered gloss surfaces resists dirt accumulation and bacterial growth, addressing hygiene concerns while maintaining visual integrity.

Air conditioner panels face unique environmental challenges that demand exceptional surface durability. Unlike automotive interiors that utilize similar high-gloss technologies, air conditioning units experience temperature extremes, UV exposure, chemical cleaning agents, and physical abrasion from maintenance activities. These combined stressors necessitate surface technologies that surpass conventional polymer capabilities. The migration from painted finishes to molded-in-color high-gloss surfaces represents not only cost efficiency but also solves the environmental compliance challenges associated with VOC emissions from painting processes.

Manufacturing high-gloss panels requires overcoming significant technical obstacles. The molding process must achieve perfect surface replication from tooling while preventing even microscopic imperfections that become glaringly visible under glossy finishes. Common defects like flow lines, weld lines, gate vestiges, and sink marks require comprehensive solutions spanning material formulation, mold engineering, and process control. The commercial impact of surface defects manifests in increased rejection rates, higher production costs, and potential brand reputation damage when flawed products reach consumers.

Beyond technical considerations, market trends indicate growing regulatory pressure and consumer demand for sustainable solutions. The European Union's circular economy action plan and similar global initiatives increasingly penalize non-recyclable material combinations and energy-intensive finishing processes. This regulatory landscape positions integrated high-gloss molding as both an aesthetic solution and strategic manufacturing approach that aligns with sustainability benchmarks through reduced processing steps and improved recyclability at end-of-life.

Selecting appropriate base polymers and additives forms the foundation for achieving durable high-gloss surfaces that maintain their reflective properties throughout the product lifecycle.

Engineering thermoplastics for high-gloss applications must satisfy contradictory requirements including sufficient flow characteristics for surface replication, inherent rigidity to resist deformation, and scratch resistance to withstand abrasive cleaning. ABS (Acrylonitrile Butadiene Styrene) remains prevalent due to its balanced properties and cost-effectiveness, though advanced grades incorporating weatherability stabilizers have become essential for preventing yellowing in UV-exposed environments. PC (Polycarbonate) alloys provide superior impact resistance necessary for larger panels prone to flexural stress during installation and operation. For applications demanding exceptional thermal and chemical resistance, manufacturers increasingly turn to PP (Polypropylene) composites incorporating mineral reinforcements that enhance dimensional stability without sacrificing surface quality.

Specialized additives transform base polymers from commodity materials into high-performance solutions for premium surfaces. Anti-scratch additives like Licowax AS 100 TP create protective surface layers that significantly reduce visible abrasion damage by altering the polymer's coefficient of friction and surface hardness characteristics. These renewable raw material-based additives enable molded plastic goods to maintain their original appearance through repeated cleaning cycles and incidental contact. For applications requiring metallic effects without secondary painting, aluminum pigment preparations like STAPA AC Reflexal deliver high-gloss reflective finishes through direct incorporation during molding. These solutions eliminate painting-related VOC emissions while achieving surface qualities exceeding conventional painted finishes.

| Material | Surface Gloss (60° GU) | Scratch Resistance | Impact Strength (J/m) | UV Stability |

|---|---|---|---|---|

| Standard ABS | 85-90 | Moderate | 200-250 | Fair |

| High-Gloss ABS w/Additives | 95+ | Excellent | 220-280 | Good |

| PC/ABS Blend | 90-93 | Good | 450-600 | Excellent |

| Reinforced PP | 88-92 | Very Good | 50-80 | Excellent |

Material consistency presents another critical consideration in high-gloss manufacturing. Variations in regrind ratios, pigment dispersion, and moisture content create subtle differences in polymer flow characteristics that manifest as surface inconsistencies. Advanced material handling systems with precision drying capabilities maintain moisture levels below 0.02% for hygroscopic polymers like PC and ABS, preventing splay marks that ruin glossy surfaces. Similarly, gravimetric blending systems ensure exact additive ratios between production runs, eliminating batch-to-batch variations that create acceptance challenges when assembling multi-panel units.

The sustainability imperative drives innovation in polymer selection beyond technical performance characteristics. Bio-based carriers and renewable raw materials reduce dependency on fossil resources while lowering product carbon footprints by up to 50% compared with conventional formulations. Material systems enabling monomaterial construction enhance recyclability by eliminating multi-layer barriers or incompatible paint systems that complicate end-of-life processing. These environmental considerations increasingly factor into material selection as manufacturers pursue comprehensive sustainability certifications while maintaining premium surface qualities.

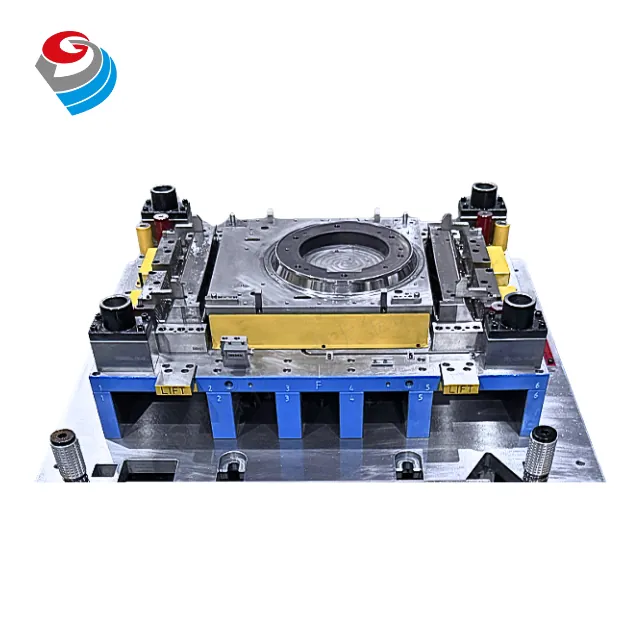

High-gloss panel production demands mold engineering that achieves optical-grade surface replication while maintaining thermal stability throughout production cycles.

Mold steel selection directly determines achievable surface quality and tool longevity in high-gloss applications. Premium hardened steels including NAK80, S136, and hardened 2738 provide the necessary combination of polishability, hardness retention, and corrosion resistance required for maintaining optical surfaces through production runs exceeding one million cycles. The polishing process progresses through increasingly fine abrasive steps culminating with diamond paste achieving surface roughness values below Ra 0.01 μm – equivalent to mirror finishes that transfer perfectly to molded components. This polishing expertise requires specialized toolroom equipment and skilled technicians capable of maintaining consistent angles and eliminating directional polishing marks that become visible on final parts.

Temperature control systems represent another critical element in high-gloss mold engineering. Conventional cooling layouts create localized temperature differentials that produce visible sink marks on finished surfaces. Conformal cooling channels that precisely follow cavity contours maintain temperature consistency within ±1°C across the molding surface, eliminating thermally-induced surface variations. For applications requiring extreme thermal control, cascading cooling circuits with turbulent flow regimes extract heat efficiently while preventing the vapor barrier effect that plagues conventional cooling channels. These advanced thermal management systems typically reduce cycle times by 15-25% while simultaneously improving surface quality through consistent thermal conditions.

| Steel Grade | Hardness (HRC) | Polishing Capability | Corrosion Resistance | Optimal Applications |

|---|---|---|---|---|

| NAK80 | 40 | Excellent | Good | High-gloss consumer panels |

| S136 | 50 | Superior | Exceptional | Medical/transparent components |

| 2738 | 35 | Very Good | Very Good | Large appliance housings |

| H13 | 50 | Good | Moderate | High-volume production |

Gate design and runner systems must balance filling requirements against cosmetic considerations. Hot runner systems with thermally balanced manifolds and individually controlled drops provide precise material delivery while eliminating runner-related material waste. Valve-gated systems offer particular advantages for high-gloss applications by providing positive shut-off that prevents material drool and strand formation that create surface defects. Gate locations require careful simulation analysis to ensure weld line placement avoids visible surfaces while maintaining balanced filling patterns that prevent differential shrinkage. Submarine gates and tunnel gates provide automatic degating solutions but require careful polishing of gate lands to prevent witness marks on finished surfaces.

Venting design prevents surface defects caused by trapped gases that create burns and poor surface replication. High-gloss tools incorporate precision venting systems with micro-machined slots measuring 0.015-0.02mm at the parting line and strategically placed vacuum venting at last-fill areas. These systems prevent gas trapping that would otherwise create localized variations in surface gloss. For exceptionally complex geometries, permeable steel inserts provide distributed venting across cavity surfaces without creating witness lines. The combination of these venting technologies ensures complete cavity replication while eliminating burn marks that would otherwise require secondary surface restoration processes.

Precision injection molding processes for high-gloss panels require exacting parameter control exceeding standard molding tolerances to achieve consistent surface quality across production runs.

Temperature regulation throughout the molding process maintains material characteristics essential for perfect surface formation. Barrel temperature profiles must transition material from solid to molten state without thermal degradation that creates surface imperfections. Melt temperature consistency within ±3°C ensures uniform viscosity critical for maintaining laminar flow fronts that prevent visible flow lines. Mold surface temperatures maintained between 80-120°C (depending on polymer) using high-precision water circulators prevent premature freezing of the material against the cavity wall. This thermal management facilitates complete cavity replication while minimizing molded-in stress that can later manifest as warpage or environmental stress cracking.

Injection speed and pressure profiling requires sophisticated control systems to achieve optimal surface formation. High initial injection velocities (up to 300mm/s) establish a stable flow front that prevents hesitation marks where material begins to solidify before filling thin sections. Velocity-to-pressure transfer points must be precisely timed to avoid over-packing or under-packing conditions that create sink marks or dimensional deviations. Multi-stage packing profiles compensate for material shrinkage characteristics, applying higher pressure initially to overcome gate resistance followed by stepped reductions that prevent over-packing stress while compensating for volumetric shrinkage. These complex profiles require servo-driven injection units capable of position control within 0.1mm to achieve consistent results.

Thermal Control Parameters:

Melt temperature variance: ≤±3°C

Mold surface temperature gradient: ≤2°C across cavity

Coolant flow rate: ≥10 liters/minute/circuit

Injection Phase Settings:

Fill time consistency: ≤0.03 seconds deviation

Peak injection pressure: 1,200-1,800 bar

Velocity-to-pressure transfer position: ±0.1mm repeatability

Holding Phase Parameters:

Packing pressure profile: 3-5 stages with ramp transitions

Holding time: Optimized to gate seal time

Back pressure consistency: ≤±2 bar

Environmental controls extend beyond the molding machine itself to encompass the entire production environment. Material handling systems must maintain moisture content below 0.02% for hygroscopic polymers through precision drying with dew points below -40°C. Cleanroom molding environments with ISO Class 8 air quality prevent particulate contamination that becomes entrapped in surfaces or creates surface imperfections during mold closing. Airflow management systems maintain positive pressure in molding areas to exclude ambient dust while temperature and humidity controls maintain environmental conditions within narrow parameters that ensure process consistency unaffected by external weather variations.

Advanced process monitoring systems collect data across multiple parameters to identify deviations before they create rejectable parts. Real-time viscosity monitoring through nozzle pressure sensors detects material variations between batches. Cavity pressure transducers mounted directly behind cavity surfaces provide the most accurate measurement of process consistency by recording actual conditions within the mold. These systems trigger automatic rejection of non-conforming parts while alerting technicians to process drift before it creates scrap. The integration of these monitoring systems with Industry 4.0 architectures creates comprehensive digital twins of the production process that enable predictive maintenance and continuous process optimization.

Post-molding surface treatments provide critical enhancements to molded-in surfaces, elevating scratch resistance and gloss retention to meet demanding application requirements.

Protective coating systems form the frontline defense against abrasion and chemical exposure in challenging environments. UV-cured coatings offer significant advantages for high-gloss panels with cure times under 5 seconds and superior scratch resistance compared to thermally cured alternatives. These formulations incorporate nano-scale silica particles that create composite surfaces with hardness ratings exceeding 3H on the pencil hardness scale while maintaining flexibility to withstand impact without cracking. Application consistency requires precision coating systems with robotic applicators maintaining uniform thickness between 15-25 microns across complex geometries. The environmental benefits of UV coatings include near-zero VOC emissions and energy consumption reductions of up to 75% compared to thermal cure systems.

For applications requiring metallic finishes without painting, in-mold lamination technologies integrate decorative foils directly during the molding process. This single-step approach bonds decorative and functional surface layers directly to the substrate material, eliminating secondary operations while producing surfaces that resist delamination under thermal cycling. Static-dissipative versions of these films prevent dust accumulation on vertical surfaces – a critical consideration for air conditioning units installed in high-particulate environments. The integration process requires specialized mold designs with precise sealing mechanisms and vacuum systems capable of evacuating air between film and cavity surface within milliseconds before material injection.

Plasma surface activation creates molecular-level changes that improve coating adhesion without altering visual characteristics of the base material. Atmospheric plasma systems treat surfaces at line speeds up to 10 meters/minute, increasing surface energy from approximately 30 dynes/cm to over 72 dynes/cm. This activation enables superior bonding of protective coatings while eliminating the environmental hazards associated with chemical adhesion promoters. The same technology provides an effective surface cleaning method immediately before coating application, removing microscopic contaminants that would otherwise create adhesion failure points. For manufacturers pursuing sustainability certifications, plasma treatment provides a dry process alternative to solvent-based surface preparation that reduces hazardous chemical usage.

Anti-fingerprint technologies represent a specialized category of surface enhancement particularly relevant to air conditioner control panels. These permanent modifications to surface energy characteristics cause oils to bead rather than spread across surfaces, significantly reducing visible fingerprints while maintaining surface transparency. The most effective solutions integrate inorganic nanoparticles into coating matrices at loadings below 5% that maintain gloss levels above 95 GU at 60° measurement angles. Accelerated testing simulating years of cleaning cycles confirms these surfaces retain their oleophobic properties through more than 5,000 cleaning cycles using common household chemicals. The combination of these technologies creates surfaces that maintain their as-manufactured appearance throughout the product lifecycle despite frequent user contact and cleaning.

Rigorous inspection protocols ensure consistent surface quality through automated measurement systems that exceed human visual capabilities in objectivity and precision.

Gloss measurement represents the fundamental quantitative assessment of surface quality, with industry standards specifying 60° geometry measurements for most applications. High-gloss panels require consistency above 90 GU (gloss units) across entire surfaces with variance below 5 GU between different production batches. Modern multi-angle spectrophotometers provide comprehensive surface characterization including gloss measurements at 20°, 60°, and 85° to detect subtle variations in surface texture. These instruments incorporate environmental standardization to prevent measurement variations caused by ambient light conditions while integrating with automated positioning systems that map surface characteristics across entire panels rather than single-point measurements.

Scratch resistance evaluation employs both quantitative and qualitative methodologies to simulate real-world conditions. Taber abrasion testing with CS-10 wheels under 500g load provides accelerated wear simulation that correlates to years of cleaning cycles. More specialized testing includes steel wool abrasion under controlled pressure to simulate the most aggressive cleaning scenarios encountered in commercial installations. For quantitative assessment, nano-scratch testers measure the exact force required to create visible surface damage at the micron level, providing early detection of surface formulation variations before they manifest in field failures. These physical tests complement visual assessments under controlled lighting conditions that simulate typical installation environments.

Critical Surface Quality Metrics:

Gloss uniformity: ≤5 GU variation across surface

Distinctness of Image (DOI): ≥90

Haze measurement: ≤0.5%

Durability Testing Standards:

Taber abrasion (500g/1,000 cycles): ≤10 GU loss

Chemical resistance: No effect after 24hr exposure to cleaners

Cross-hatch adhesion: Class 0 per ASTM D3359

Electrical Properties:

Surface resistance: 107-109Ω (prevents dust accumulation)

Static decay: ≤0.5 seconds from 5kV to 500V

Color consistency requires sophisticated instrumentation capable of detecting subtle variations imperceptible to the human eye under standard inspection conditions. Spectrophotometers with large measurement apertures (25mm or greater) provide spatial averaging that accommodates natural material variations. Instrument grading under D65 daylight illumination provides the most relevant assessment of color matching for products installed in residential and commercial environments. Advanced systems incorporate surface texture analysis that accounts for how directional polishing or texturing affects color perception under different viewing angles. These comprehensive measurements ensure consistent appearance when replacing individual panels years after original installation.

Dimensional verification maintains critical functional characteristics while preserving surface quality. Coordinate measuring machines (CMM) with non-contact laser scanners capture entire surface profiles without risking damage to delicate finishes. These systems verify flatness within 0.1mm/m to prevent visible distortion in large panels while confirming critical interface dimensions for assembly. The integration of CMM data with mold flow simulation creates closed-loop correction systems that automatically adjust process parameters to compensate for material variability detected through viscosity monitoring. This comprehensive approach ensures dimensional stability without compromising the surface perfection achieved through precise mold engineering and processing controls.

Emerging technologies in polymer science, mold manufacturing, and surface engineering promise to elevate high-gloss panel performance while addressing sustainability imperatives through material and energy efficiency improvements.

Self-healing polymer technology represents the frontier in surface durability research, with microencapsulated healing agents activated by scratch damage to restore surface integrity. When surface abrasion ruptures microcapsules embedded near the surface, liquid healing agents flow into damaged areas through capillary action before polymerizing to restore optical properties. Current development focuses on integrating these self-repair mechanisms without compromising initial gloss levels or creating haze that diminishes visual quality. Commercial implementation will significantly reduce visible wear over product lifetimes while potentially eliminating the need for protective hardcoats in some applications.

Intelligent mold systems incorporating active surface elements enable dynamic surface adjustment during production. Piezoelectric actuators embedded below mold surfaces compensate for thermal distortion in real-time, maintaining cavity dimensional stability throughout production cycles. These systems integrate with cavity pressure sensors to create closed-loop control of surface formation conditions, automatically adjusting for material variations that would otherwise create visible defects. Future iterations will incorporate direct surface texture modification capabilities, potentially enabling single molds to produce multiple surface finishes on-demand without physical tool changes. These technologies promise unprecedented flexibility in high-gloss manufacturing while maintaining quality consistency previously unattainable with conventional tooling.

Sustainable material innovations focus on closed-loop systems that maintain performance while reducing environmental impact. Chemical recycling advancements enable food-grade PCR (Post-Consumer Recycled) content incorporation in high-gloss applications previously restricted to virgin materials due to purity requirements. Bio-based engineering plastics derived from non-food biomass now achieve property parity with petroleum-based counterparts while reducing carbon footprints by 40-60% across product lifecycles. These materials increasingly incorporate built-in compatibilizers that allow higher regrind utilization without surface quality degradation. The convergence of these technologies supports industry sustainability targets without compromising the premium surface qualities demanded by consumers.

Digital twin technology extends beyond process monitoring to encompass comprehensive surface prediction systems. Advanced simulation platforms now incorporate material rheology data, mold thermal analysis, and process parameters to predict surface outcomes before tool commissioning. These virtual models enable mold designs optimized specifically for high-gloss outcomes through predictive correction of potential problem areas before steel cutting. Post-production, these digital twins continue refining their algorithms based on actual production data, creating continuously improving predictive accuracy. The implementation of these systems reduces development time for new high-gloss applications from months to weeks while eliminating costly tool modifications traditionally required to achieve surface perfection.

The integration of these innovations establishes a new paradigm for high-gloss panel production where sustainability, efficiency, and surface perfection coexist rather than representing competing priorities. Manufacturers adopting these integrated approaches position themselves to lead in premium appliance markets where surface excellence represents not merely an aesthetic consideration but a manifestation of technological leadership and commitment to quality throughout the product lifecycle.

content is empty!

content is empty!

ZHUHAI GREE DAIKIN PRECISION MOLD CO., LTD.