Views: 0 Author: Site Editor Publish Time: 2025-06-05 Origin: Site

Injection molding dominates modern manufacturing, accounting for 32% of global plastic processing (industry estimates). This technology enables mass production of high-precision components across industries like automotive, consumer electronics, and medical devices. The quality of molds directly impacts product tolerances (±0.02–0.05mm for precision molds) and production costs, with poorly designed molds increasing scrap rates by up to 15%.

The injection mold manufacturing process involves five critical phases:

(1) Design for Manufacturability (DFM) analysis

(2) mold design and simulation

(3) precision machining

(4) surface treatment and assembly

(5) testing and optimization

Advanced technologies like AI-driven mold flow analysis and 5-axis CNC machining ensure <2μm precision in modern tooling.

Injection molding stands as a cornerstone of modern manufacturing, accounting for over 30% of global plastic production. This versatile process enables the mass fabrication of complex, high-precision components across industries, from automotive to medical devices.

1.1 Precision and Scalability:

Injection molding achieves tolerances as tight as ±0.001 inches, making it indispensable for producing intricate parts like microgears, medical implants, and automotive connectors. Its automated workflows allow manufacturers to produce millions of identical units with minimal defects—critical for industries like electronics, where components such as smartphone housings and circuit board mounts require millimeter-level accuracy.

1.2 Cross-Industry Applications:

Automotive: Lightweight components (e.g., bumpers, dashboards) reduce vehicle weight, improving fuel efficiency.

Medical: Sterile, biocompatible devices like syringes and surgical tools are produced with ISO-certified precision.

Consumer Goods: Durable household items (e.g., plastic containers, toys) are manufactured at low per-unit costs.

Electronics: Complex geometries for connectors and enclosures ensure protection and functionality in devices.

1.3 Economic Efficiency:

While initial mold costs can reach 10,000–100,000, the per-unit cost drops exponentially at scale. For example, producing 100,000 plastic caps reduces individual costs to 0.02–0.05, compared to 5–10 for small batches. Advanced mold designs and materials like hardened steel (H13, S136) further extend tool life to 500,000–1 million cycles, maximizing ROI.

1.4 Sustainability and Innovation:

Over 85% of thermoplastic waste in injection molding is recycled back into production, aligning with circular economy goals. Emerging trends like bio-based polymers and hybrid molds with conformal cooling channels reduce energy consumption by 20–30% while maintaining cycle efficiency.

The injection mold manufacturing process is a meticulously orchestrated sequence that integrates design optimization, precision engineering, and advanced manufacturing technologies.

Below is a comprehensive breakdown of each stage, supported by industry benchmarks and technical insights.

DFM ensures product designs align with manufacturing capabilities, minimizing defects and costs.

Product Design Validation

Draft Angle Optimization: Ensure minimum 1° draft angles for smooth ejection.

Wall Thickness Uniformity: Maintain ±10% variation to prevent sink marks and warping.

Gate Positioning: Use mold flow analysis to simulate resin flow and avoid air traps.

Key Activities:

Tools: Automated DFM software provides instant feedback on design flaws (e.g., undercuts, thin walls).

Material Selection

Thermal Stability: High-performance resins like PEEK require molds with hardened steel (H13, S136).

Cycle Life: Tool steels (e.g., P20) are cost-effective for medium-volume production, while beryllium copper alloys excel in rapid cooling.

Mold Flow Simulation

Predicts filling time (±0.5s), cooling efficiency (ΔT <5°C), and warpage risk.

Reduces trial cycles by 50% through virtual defect detection.

Precision mold design determines part quality, cycle time, and tool longevity.

Core Design Elements

Cavity/Core Plates: Split designs align with parting lines to minimize flash.

Cooling System: Conformal channels reduce cycle time by 30% and prevent thermal deformation.

Ejection System: Optimized pin placement avoids part damage during demolding.

CAD Modeling & Analysis

Undercut Analysis: Identify features requiring slides or lifters.

Venting Design: Micro-grooves (0.02–0.05mm depth) prevent gas traps.

Critical Checks:

Material Compatibility

Material | Hardness (HRC) | Best For | Cycle Life |

|---|---|---|---|

P20 Steel | 28–32 | Medium-volume production | 500,000 cycles |

H13 Steel | 48–52 | High-wear applications | 1M+ cycles |

Aluminum | 20–25 | Prototyping | 50,000 cycles |

Advanced machining ensures micron-level accuracy and durability.

CNC Machining

5-Axis CNC: Achieves ±0.005mm tolerances for complex geometries.

EDM/Wire Cutting: Creates sharp edges (Ra 0.4μm) for micro-features.

Surface Enhancements

Polishing: Mirror finishes (Ra 0.02μm) reduce friction and improve part release.

Chrome Plating: Adds 5–10μm Cr2O3 layer for corrosion resistance.

Texture Etching: Laser texturing creates functional surfaces (e.g., grip patterns).

Quality Control

CMM Inspection: Verifies dimensional accuracy (±0.001mm).

Tooling Trials: Test shots validate mold performance under production conditions.

Final assembly integrates components for seamless production readiness.

Component Integration

Ejector Pins: Aligned within 0.01mm to prevent misalignment.

Cooling Line Leak Testing: 30% overpressure checks ensure no coolant leakage.

Process Validation

Scientific Molding: Data-driven parameter optimization (e.g., 80–120MPa injection pressure).

In-Mold Sensors: Monitor real-time temperature (±1°C) and pressure (±0.5%).

Continuous Improvement

Root Cause Analysis: Address defects like brittleness (e.g., moisture control, regrind limits).

Predictive Maintenance: IoT-enabled molds track wear and schedule repairs.

Efficient production relies on optimized parameters and sustainability practices.

Cycle Time Reduction

Conformal Cooling: Cuts cooling time by 25–40%.

High-Speed Injection: 500–1,000mm/s speeds reduce fill time.

Sustainability Measures

Material Recycling: 85% thermoplastic regrind reuse.

Energy-Efficient Machines: All-electric presses reduce energy use by 30%.

The injection mold industry is undergoing a transformative shift, driven by advancements in precision machining, smart manufacturing, and sustainable practices.

Below is an in-depth analysis of cutting-edge technologies and emerging trends shaping the future of mold manufacturing.

Advanced machining techniques are redefining precision standards, enabling micron-level tolerances and complex geometries.

5-Axis CNC Machining:

Modern 5-axis CNC systems achieve ±0.005mm accuracy for intricate mold components like micro-cavities and freeform surfaces. By eliminating multiple setups, this technology reduces machining time by 30–50% while improving surface finish (Ra ≤0.4μm). Applications include optical lens molds and medical implants requiring sub-micron precision.

Hybrid Additive Manufacturing:

Combining traditional CNC with additive techniques (e.g., DMLS) allows the creation of conformal cooling channels within molds. These channels optimize thermal management, reducing cycle times by 25–40% and minimizing warpage defects.

Micro/Nano-Injection Molding:

Specialized machines and molds now produce parts with features as small as 10μm, critical for micro-sensors and wearable devices. Laser-textured surfaces (Ra 0.1–10μm) enhance functionality, such as anti-reflective coatings for optical components.

IoT, AI, and data-driven systems are revolutionizing process control and predictive maintenance.

AI-Driven Mold Flow Simulation:

Tools like Autodesk Moldflow use machine learning to predict filling patterns, cooling efficiency, and warpage risks with >85% accuracy. This reduces trial cycles by 50% and minimizes material waste.

In-Mold Sensor Networks:

Embedded sensors monitor real-time parameters like temperature (±0.5°C) and pressure (±0.5 MPa), enabling dynamic adjustments during production. For example, automotive manufacturers use this data to maintain ±0.01mm part consistency across million-cycle runs.

Digital Twins and Industry 4.0:

Virtual replicas of molds simulate performance under varying conditions, optimizing parameters like clamping force and injection speed. Companies adopting digital twins report 20–30% faster time-to-market and 15% lower energy consumption.

The industry is prioritizing energy efficiency and circular economy principles.

Bio-Based and Recycled Materials:

Molds designed for biodegradable polymers (e.g., PLA) and recycled thermoplastics reduce carbon footprints. For instance, food packaging molds using recycled PET cut material costs by 25% while meeting FDA compliance.

Energy-Efficient Machines:

All-electric injection molding machines consume 30–50% less energy than hydraulic counterparts. Regenerative braking systems further recover energy during deceleration, achieving ISO 50001 sustainability standards.

Closed-Loop Recycling:

Advanced regrind systems reuse 85–90% of thermoplastic waste within production cycles. Automotive suppliers like Intretech integrate this technology to achieve zero-landfill targets.

Next-generation technologies are unlocking unprecedented capabilities.

AI-Optimized Design (Generative AI):

Algorithms generate lightweight, high-strength mold structures by analyzing stress distribution and material properties. This reduces material usage by 15–20% while improving durability.

Robotic Polishing and Assembly:

Collaborative robots (cobots) equipped with vision systems perform mirror polishing (Ra 0.02μm) and precision assembly, achieving 99.9% defect-free outputs in medical mold production.

Smart Surface Treatments:

Innovations like plasma-enhanced PVD coatings extend mold lifespan by 3–5×, even with abrasive resins like glass-filled nylon. Chrome plating and nano-ceramic layers also enhance corrosion resistance.

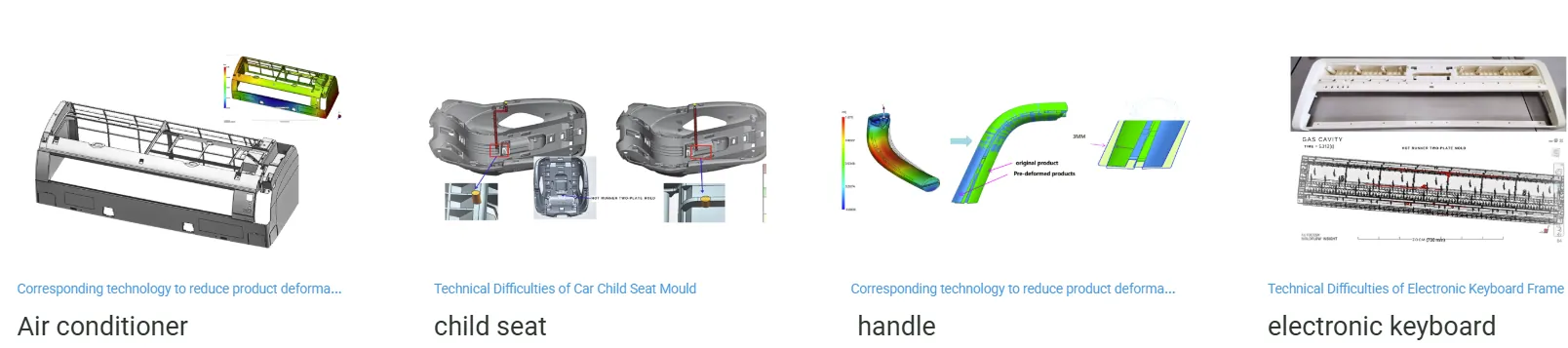

Zhuhai Gree Daikin Precision Mold Co., Ltd. (GDM) is a leading integrated solutions provider in injection molding, with 30 years of expertise in full-cycle mold development—from product feasibility analysis and mold design to mass production maintenance. Leveraging cutting-edge R&D capabilities, we specialize in high-precision molds (±0.005mm tolerance) for nine key industries, including home appliances, automotive components, medical devices, and new energy equipment, serving 500+ global clients.

• Deformation Control: Optimized cooling systems + mold flow analysis + pressure-holding simulations reduce deformation to <0.15mm for large components like AC panels.

• Gas-Assisted Molding: Multi-physics coupling analysis precisely locates gas channels, eliminating weld lines in electronic keyboard frames.

• Thin-Wall Molding: Moldflow® simulations enable 1.2mm wall thickness for child seat molds while maintaining structural integrity.

• Smart Trial System: Full-range trial machines (1300T to 180T) support rapid prototyping and on-site process validation.

Mold Optimization Hub

Lifecycle prediction system extends mold durability by 30%

Integrated painting-free molding reduces post-processing costs by 25%

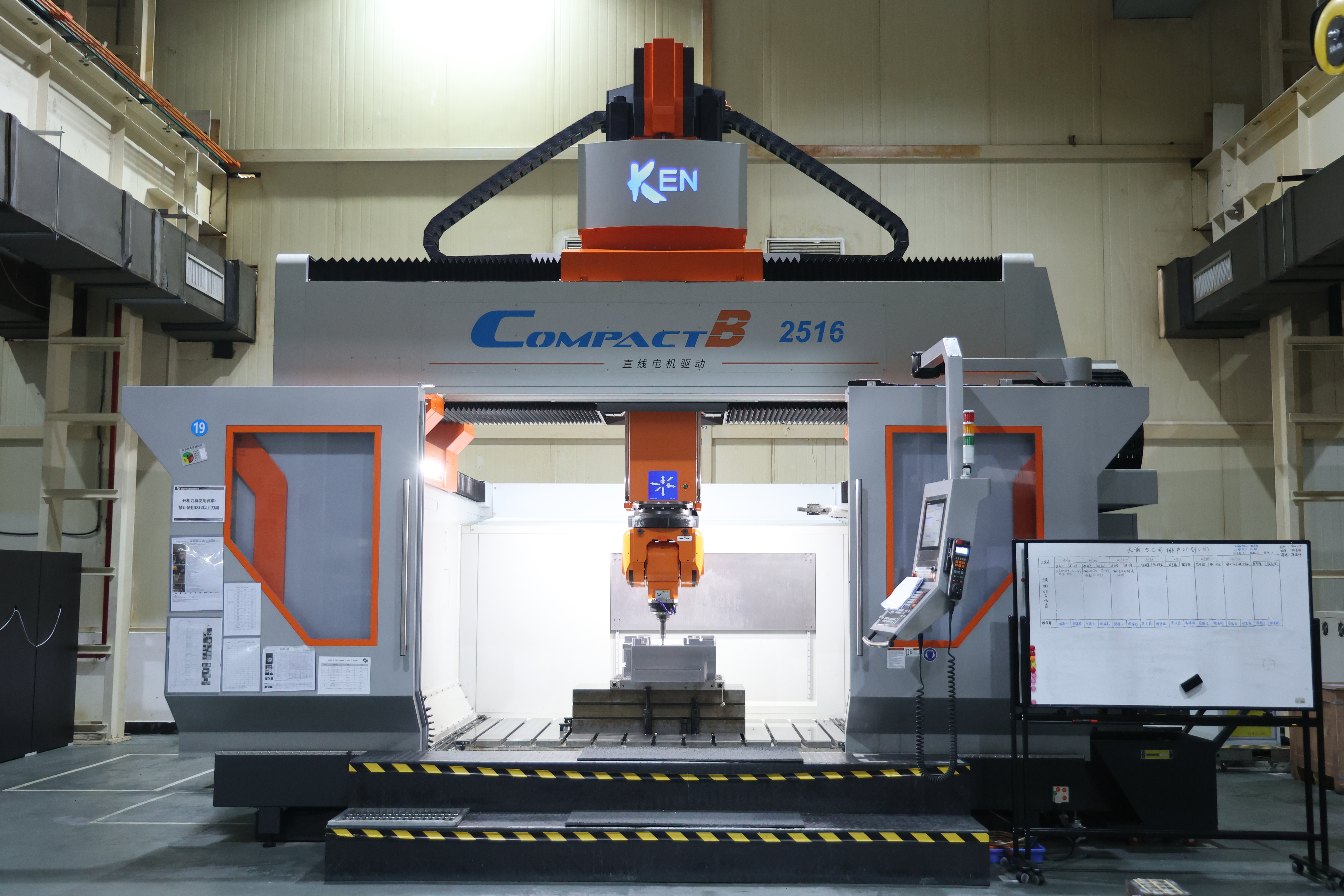

Precision Production Lines

200+ high-precision 5-axis machining centers

40% faster graphite electrode processing

In-line CMM inspection ensures 100% dimensional compliance

Quality Assurance Framework

Three-tier quality gates: CAE analysis, trial validation, mass-production monitoring

72-hour global after sale service

Bilingual engineering support (EN/JP)

GDM’s vision for the future of injection molding is anchored in three transformative pillars: intelligent automation, sustainable manufacturing, and globalized collaboration. These strategic priorities will redefine industry standards, drive operational excellence, and deliver unparalleled value to clients worldwide.

Technical Implementation

AI-Optimized Mold Design:

Deploying proprietary algorithms trained on 200,000+ historical datasets to automate critical processes:

▸ Gate Placement Intelligence: Reduce filling imbalance from 8% to <1.5% through dynamic flow simulations.

▸ Self-Generating Ejection Systems: Cut design time by 40% while improving pin-stress uniformity by 90%.

▸ Real-Time Collision Detection: Eliminate 95% of tooling conflicts via physics-based digital twins.

Smart Production Cells:

Integrating IoT sensors with 1300T–180T presses to enable:

▸ Self-Adjusting Parameters: Auto-calibrate clamping force (±1.5%) and cooling rates based on material viscosity shifts.

▸ Predictive Maintenance: Reduce unplanned downtime by 60% through vibration/temperature anomaly detection.

Technical Implementation

Circular Material Systems:

▸ Bio-Based Resins: Launching 15+ grades of carbon-neutral polymers by 2026, validated by ISO 14067 certifications.

▸ Closed-Loop Recycling: Achieve 98% regrind reuse in high-gloss consumer electronics housings.

Energy-Neutral Factories:

▸ Solar-Powered Presses: Offset 35% of energy demand via rooftop PV systems by 2027.

▸ Hydraulic Hybrids: Cut power consumption by 45% in 1000T+ machines through servo-driven pumps.

Zero-Waste Tooling:

▸ Waterless Cooling: Adopt graphene-enhanced conformal channels to eliminate 12,000 tons/year of wastewater.

▸ AI Waste Analytics: Reduce material overfill by 22% through predictive shot-volume optimization.

Technical Implementation

Unified Digital Platform:

▸ Cloud-Based Co-Design: Enable real-time collaboration across 20+ time zones with VR-enabled design reviews.

▸ Standardized Tooling Libraries: 5,000+ pre-validated mold components compatible with ENGEL, ARBURG, and Haitian presses.

Regional Innovation Hubs:

▸ Europe (2025): Stuttgart tech center specializing in automotive micro-molding (±0.02mm).

▸ North America (2026): Michigan hub for medical-grade silicone overmolding solutions.

Agile Supply Chains:

▸ Blockchain Traceability: Guarantee material origins for FDA/REACH compliance.

content is empty!

content is empty!

ZHUHAI GREE DAIKIN PRECISION MOLD CO., LTD.