Views: 0 Author: Site Editor Publish Time: 2025-07-29 Origin: Site

The manufacturing of large home appliance components like refrigerator panels, oven housings, and washing machine chassis demands extraordinary precision at production scale. Progressive die stamping has emerged as the dominant manufacturing method for these sheet metal parts, combining multiple operations—blanking, punching, bending, and forming—into a continuous, high-speed process. Yet achieving first-trial success (getting the part right on the initial production run) remains an elusive goal for many manufacturers, as dimensional inaccuracies, material springback, and tooling misalignments can derail production timelines and inflate costs by 20-35% .

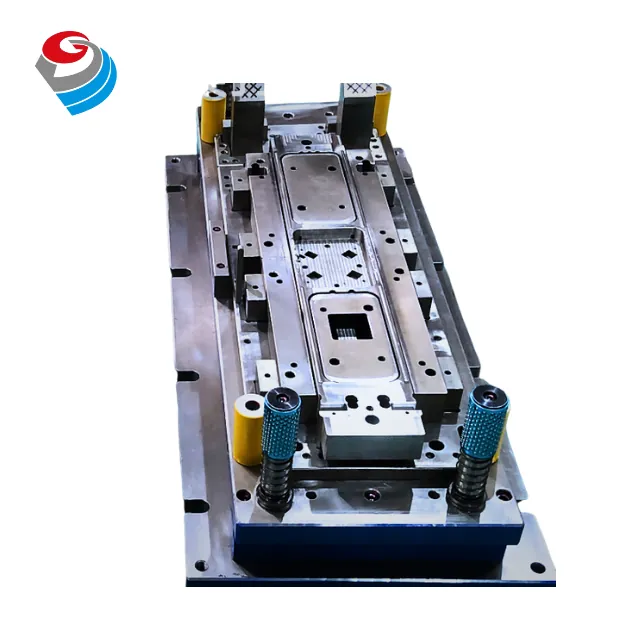

First-trial success in progressive dies for large appliances hinges on seven core technologies: advanced simulation software for predicting material behavior, precision tooling systems with conformal cooling, data-driven process parameter optimization, adaptive press control systems, high-strength tool steels with specialized coatings, real-time monitoring with closed-loop feedback, and integrated surface treatment protocols.

The complexity of large-panel progressive stamping arises from multiple interacting variables—material thickness variations, press dynamics, thermal expansion of dies, and elastic recovery of metals after forming. When producing refrigerator door panels or washing machine tubs, deviations as small as 0.1mm can cause assembly failures or visible surface defects. With appliance manufacturers facing compressed product development cycles and rising quality expectations, mastering first-trial success has transitioned from competitive advantage to operational necessity. This analysis examines the technical infrastructure required to achieve zero-defect initial runs in high-volume appliance manufacturing, reducing time-to-market while eliminating costly die rework .

The Strategic Imperative of First-Trial Success in Appliance Manufacturing

Precision Tooling Design with Conformal Cooling Systems

Advanced Simulation Technologies for Predicting Material Behavior

Material Selection and Springback Compensation Strategies

Press and Bending Process Control Systems

Integrated In-Process Monitoring and Adaptive Control

Surface Treatment and Finishing Integration

Emerging Technologies for Zero-Defect Production Launch

First-trial success in progressive die stamping directly impacts time-to-market, tooling costs, and production economics for large home appliance components, where dimensional accuracy exceeding±0.05mm is required for seamless assembly and aesthetic perfection.

In appliance manufacturing, progressive dies represent substantial capital investments ranging from $250,000 to over $1 million for complex refrigerator panel tooling. Each day of rework delays production launch and postpones ROI realization. More critically, dimensional errors discovered during trial runs typically require steel welding, re-machining, or even complete section replacement—operations that consume 3-8 weeks and add 15-30% to tooling costs [1](@ref). For high-volume components like dishwasher side panels or oven cavities, production delays cascade through assembly lines, creating inventory imbalances and missed shipment targets that impact customer relationships.

The scale of large appliance components introduces unique challenges absent in smaller stamped parts. When forming a refrigerator door panel spanning 0.8m × 1.8m, minute variations in material thickness—common even in premium cold-rolled steel—compound across the surface, creating warpage or inconsistent bend angles. Similarly, thermal expansion in large dies during high-speed production can reach 0.15mm across the tool face, necessitating active thermal management systems to maintain dimensional stability. These factors, combined with the stringent cosmetic requirements of consumer-facing surfaces, elevate the precision requirements beyond typical automotive or industrial applications [1,4](@ref).

Market pressures further intensify the need for first-trial success. Appliance development cycles have compressed from 24 months to under 14 months in the past decade, leaving no buffer for tool rework. Simultaneously, customization trends have increased part variety, requiring faster tooling changeovers. Manufacturers achieving consistent first-trial success gain competitive advantages through reduced development costs and accelerated response to design changes—capabilities increasingly critical in an industry where energy efficiency standards and consumer preferences evolve rapidly.

High-precision tooling incorporating conformal cooling channels provides the thermal stability necessary for maintaining micron-level tolerances in large appliance panel production, reducing thermal distortion by 60-80% compared to conventional cooling methods.

Tool steel selection establishes the foundation for dimensional stability in large progressive dies. For appliance panels requiring over 1 million cycles, premium steels like hardened 2738 (HRC 35) or NAK80 (HRC 40) provide optimal balance between polishability, hardness retention, and thermal conductivity. These alloys withstand the abrasive wear common when processing stainless steel or coated aluminum sheets while resisting thermal fatigue cracking that plagues lower-grade steels. The polishability of these alloys enables surface finishes below Ra 0.015μm—essential for high-gloss appliance surfaces where even microscopic tool marks transfer visibly to finished parts [1,4](@ref).

Conformal cooling technology represents a paradigm shift in thermal management for large dies. Unlike straight-drilled cooling channels that follow simple linear paths, conformal channels precisely contour the die geometry, maintaining consistent distance (±0.5mm) from forming surfaces. Manufactured via metal 3D printing, these turbulent-flow channels extract heat efficiently, reducing thermal gradients across large die sections to under 2°C compared to 8-15°C in conventionally cooled tools. This thermal uniformity virtually eliminates localized expansion that causes dimensional drift during extended production runs. For large refrigerator door panels, this technology reduces flatness variation from 0.8mm to under 0.1mm across the 1800mm dimension .

| Steel Grade | Hardness (HRC) | Thermal Conductivity (W/m·K) | Polishing Capability | Optimal Application |

|---|---|---|---|---|

| NAK80 | 40 | 50 | Excellent | High-gloss surface panels |

| 2738 Mod | 35 | 42 | Very Good | Large structural components |

| H13 | 50 | 25 | Good | High-wear punching sections |

| S7 | 58 | 30 | Moderate | Cutting and trimming stations |

Die component alignment systems provide additional precision assurance for large panels. Self-locking wedge systems maintain parallelism between upper and lower die shoes within 0.01mm/m, preventing angular misalignment that causes inconsistent bend angles across wide panels. Guided punch retainer plates with oversized ball-bearing sleeves accommodate thermal expansion without binding, while nitrogen-loaded stripper plates deliver uniform stripping force across large surfaces. These systems work synergistically to maintain dimensional consistency despite the tremendous forces (up to 2,500 tons) involved in forming appliance-grade stainless steel or aluminum alloys .

Physics-based forming simulation software incorporating anisotropic material models and thermal-structural coupling enables accurate prediction of springback, thinning, and stress distribution before tool fabrication, reducing trial iterations by 70-85%.

Modern finite element analysis (FEA) platforms like AutoForm or LS-DYNA have transformed die engineering from trial-and-error to predictive science. These tools simulate the complex interplay between sheet metal and die surfaces using material models that account for anisotropic behavior—critical for appliance panels formed from rolled sheets with pronounced grain directionality. Advanced solvers now incorporate temperature-dependent yield criteria and evolving friction coefficients throughout the forming stroke, accurately predicting localized thinning that could compromise structural integrity in washing machine drums or oven cavities .

Springback prediction algorithms represent the most significant advancement for first-trial success. By analyzing stress distribution through the entire forming history and calculating elastic recovery after tool release, modern software predicts springback angles within 0.5° accuracy for complex geometries. This enables virtual compensation during die design—intentionally over-forming components so they spring back to the intended shape. For large U-bends in refrigerator cabinet sides, this prevents assembly gaps exceeding 1.5mm that would otherwise require shimming during production. The software also identifies areas requiring enhanced restraint through draw beads or pressure pads to control material flow and minimize springback variability.

Cloud-based simulation platforms enable collaborative optimization throughout the tooling development cycle. Tooling engineers, material suppliers, and appliance designers can virtually validate designs against production-intent materials before steel cutting. This cross-functional approach identifies potential conflicts early—such as stainless steel's higher springback tendency compared to cold-rolled steel—allowing for adjustments before tool fabrication. Simulation reports generate actionable data including recommended blankholder force profiles, press velocity curves, and optimal lubrication patterns to ensure stable metal flow during initial trials.

Material specification extending beyond standard grades to include forming characteristic certifications, combined with physics-based springback compensation, achieves dimensional accuracy below ±0.1mm for large appliance panels despite inherent material variability.

Appliance manufacturers increasingly specify materials with certified forming characteristics to reduce production variability. Beyond standard ASTM or EN mechanical properties, these certifications guarantee consistent plastic anisotropy (r-values) and work hardening exponents (n-values) across coil lengths and between batches. For critical components like stainless steel oven fronts, specifications may include restricted yield strength variation (±15 MPa versus standard ±30 MPa) and tighter thickness tolerances (±0.03mm instead of ±0.05mm). While these premium materials cost 8-12% more, they eliminate major sources of dimensional variation that complicate first-trial success [4](@ref).

Springback compensation employs multiple complementary strategies tailored to specific panel geometries. For simple flanges, traditional methods like overbending remain effective—adding 2-8° beyond the target angle depending on material thickness and tensile strength. Complex curvilinear bends require surface-based compensation where the entire die face is offset based on FEA-predicted springback. The most advanced systems employ morphing algorithms that iteratively adjust CAD models until simulated springback produces the desired net shape. This multi-stage approach achieves accuracies within 0.05mm for complex refrigerator door profiles that would otherwise require manual rework during trials.

| Compensation Method | Accuracy Achievable | Implementation Complexity | Optimal Application Scope |

|---|---|---|---|

| Angular Overbending | ±0.5° | Low | Simple linear bends |

| Surface Offsetting | ±0.15mm | Medium | Contoured panels with 3D curvature |

| FEA-Based Morphing | ±0.05mm | High | Complex assemblies with mating surfaces |

| Adaptive CNC Toolpaths | ±0.03mm | Very High | High-gloss cosmetic surfaces |

Tooling surface treatments further enhance dimensional consistency. Physical vapor deposition (PVD) coatings like CrAlN reduce friction coefficients by 40-60% compared to uncoated tool steel, ensuring consistent material flow during forming. For aluminum appliance panels prone to galling, specialized diamond-like carbon (DLC) coatings prevent material pickup that creates surface defects. These coatings maintain consistent friction characteristics throughout production runs, preventing the gradual changes in material flow that complicate springback during extended trials .

Servo-electric press technology with programmable slide motion profiles and adaptive bending angle control achieves repeatable forming accuracy below ±0.1° for critical appliance panel bends across varying material lots.

Modern servo presses revolutionize large panel forming through programmable slide kinematics. Unlike conventional mechanical presses constrained by fixed motion curves, servo models allow independent control of approach speed, forming velocity, and dwell time. For complex refrigerator panel forming, slow approach (10-50 mm/s) ensures precise engagement with the blank, followed by high-speed forming (150-300 mm/s) to complete the stroke before material hardening occurs. Dwell periods at bottom dead center (BDC) allow stress relaxation that reduces springback by 15-30% for high-strength materials.

Adaptive bending angle control systems compensate for material variability in real-time. These systems employ in-die angle measurement probes that verify bend angles at multiple locations immediately after forming. When deviations exceed ±0.15°, the controller automatically adjusts press parameters—typically increasing forming tonnage by 5-10% or extending dwell time by 0.2-0.5 seconds—to bring subsequent parts within tolerance. For large oven cabinet panels requiring multiple bends, this closed-loop control maintains angular consistency below ±0.25° despite variations in material yield strength that would otherwise require manual intervention during trials .

Intelligent blank holder force (BHF) control prevents wrinkles while minimizing thinning in deep-drawn sections. Multi-point hydraulic cushion systems apply spatially variable pressure across large binder areas, increasing force near draw beads where material pull-in creates tension peaks. Pressure profiling throughout the forming stroke prevents fracture in critical areas like refrigerator door corners while suppressing wrinkling in low-strain zones. These systems typically incorporate 8-16 independently controlled pressure zones for large appliance panels, optimizing material flow without compromising production speed.

Real-time monitoring systems employing distributed IoT sensors and machine learning algorithms detect deviations during initial trial runs, enabling immediate corrections before dimensional errors propagate through subsequent stations.

Cavity pressure mapping provides the most direct measurement of forming consistency across large panels. Strategically placed piezoelectric sensors behind forming inserts detect pressure variations as small as 0.5 bar, indicating material flow inconsistencies or lubrication variations. During initial trials, these sensors establish baseline pressure curves for acceptable parts. Subsequent strokes are compared against this golden signature, with deviations beyond ±10% triggering automatic press stoppage to prevent producing scrap components. For large washing machine front panels, 15-30 sensors typically monitor critical features to ensure uniform material distribution.

Optical in-line measurement systems perform non-contact dimensional verification at production speeds. High-resolution cameras combined with structured light projectors create 3D surface maps of each panel between stations, comparing against nominal CAD models with accuracy below 0.05mm. When springback exceeds predicted values or thermal drift causes progressive dimensional changes, the system alerts technicians before parts exceed tolerance limits. These systems are particularly valuable for monitoring flatness across large refrigerator door panels where manual measurement would require removal from the production line.

Critical Real-Time Monitoring Parameters:

Cavity pressure profile variance: ≤±5% from golden signature

Punch penetration depth consistency: ±0.02mm

Material thickness variation: ≤±0.03mm across blank

Automated Response Protocols:

Tonage adjustment range: ±10% nominal press capacity

Dwell time correction: 0.1-1.0 second increments

Lubrication flow adjustment: ±15% from baseline

Predictive Thresholds for Intervention:

Springback deviation: >±0.3° from nominal

Thinning percentage: >25% of initial material thickness

Panel flatness deviation: >0.5mm/m

Thermal monitoring networks track die temperature gradients that could cause dimensional drift. Infrared sensors and embedded thermocouples map temperature distribution across large die sets with 1°C accuracy. When thermal expansion threatens to exceed 0.05mm across critical features, the system increases conformal cooling flow rates or temporarily reduces stroking speed to restore thermal equilibrium. This prevents progressive dimensional changes during extended trial runs where hundreds of consecutive strokes gradually heat the tooling .

In-die surface enhancement technologies and inline finishing processes ensure cosmetic perfection and functional durability of appliance panels without secondary operations, achieving MIL-SPEC surface integrity standards directly from the press.

In-die texturing transfers precisely controlled surface finishes directly during forming, eliminating secondary blasting or etching operations. Laser-ablated tool surfaces create textures ranging from mirror finishes (Ra 0.05μm) to matte patterns (Ra 1.5μm) that hide fingerprints and minor scratches. For stainless steel refrigerator doors, this technology produces consistent grain patterns across large surfaces—a task nearly impossible with post-forming processes. The same technology creates functional textures like non-slip surfaces on washer top panels or light-diffusing patterns on control consoles.

Integrated deburring stations within the progressive die eliminate secondary finishing operations. High-speed carbide rotary tools mounted in the die immediately trim burrs after cutting or piercing operations. For softer materials like aluminum appliance panels, cryogenic deburring stations expose edges to -196°C liquid nitrogen before mechanical breaking, creating micro-fractures that produce clean edges without material deformation. These integrated solutions ensure cut-edge quality exceeding ISO 13715 class F standards directly from the press line.

Surface conversion treatments applied inline enhance corrosion resistance and paint adhesion. Electropolishing stations integrated after final forming remove 5-10μm of surface material, eliminating micro-burrs and creating passivated surfaces ideal for painted finishes. For stainless steel components, in-die electrochemical treatments create consistent oxide layers that enhance stain resistance. These integrated processes ensure surface quality meeting ASTM B117 salt spray resistance exceeding 500 hours without separate processing lines—critical for dishwasher tubs and refrigerator condensate pans exposed to moisture.

Fourth-generation smart tooling systems incorporating self-adjusting components and machine learning algorithms promise to eliminate trial runs entirely by autonomously compensating for material variations and environmental factors.

Self-calibrating die systems represent the frontier of first-trial success technology. These systems employ piezoelectric actuators embedded beneath forming surfaces that dynamically adjust tool geometry in response to sensor data. During initial strokes, the system automatically compensates for detected springback by micro-adjusting form radii or bend angles within ±0.05mm. For large oven cavity forming, this technology adapts to material thickness variations across the blank, maintaining consistent depth despite incoming material inconsistencies that would traditionally require manual intervention.

Machine learning platforms analyze historical trial data to predict optimal settings for new components. By correlating material certifications, die designs, and press parameters with dimensional outcomes across thousands of previous jobs, these systems recommend settings proven to achieve first-trial success for similar geometries. As more data accumulates, the algorithms continuously refine their predictions, reducing setup time for new dies from days to hours. The integration of these systems with Industry 4.0 architectures enables knowledge sharing across manufacturing networks while preserving proprietary data within secure boundaries .

Digital twin technology creates virtual replicas of the entire production system, simulating interactions between press dynamics, material behavior, and tooling characteristics. Unlike traditional FEA that models individual operations, these comprehensive digital twins predict system-level behaviors including vibration-induced variations, thermal expansion effects on press parallelism, and material handling influences on blank positioning accuracy. By identifying potential failure modes before physical trials begin, manufacturers can implement corrective measures proactively—transforming the traditional trial run from a problem-discovery mission to a simple verification of predicted outcomes.

The convergence of these technologies establishes a new paradigm where first-trial success becomes the expected outcome rather than the aspirational goal. For appliance manufacturers competing in global markets, mastering these technologies delivers not only cost savings but also the agility to introduce innovative designs rapidly while maintaining the quality standards demanded by consumers and regulatory bodies worldwide.

content is empty!

content is empty!

ZHUHAI GREE DAIKIN PRECISION MOLD CO., LTD.