Views: 0 Author: Site Editor Publish Time: 2025-07-03 Origin: Site

■Background

With the upgrade of air-conditioning energy efficiency in 2020, the group simultaneously developed dies for multiple stamping dies, and many internal function keys were made universal, which led to an increase in production demand. The existing one-hit-one part production efficiency could not meet the order volume, and the stampig department was facing delivery pressure.

■Purpose

To meet the needs of production orders. Improve production efficiency, reduce unit production costs, and enhance the market competitiveness of enterprises. As the small-tonnage (200-ton) punch presses within the group are being gradually eliminated, the new plans are all large-tonnage punch presses. The continuous molds of the base and valve brackets were previously produced by 200-250-ton punch presses. In order to cooperate with the production planning of the new production line, the base and valve brackets will be produced by large equipment 400T punch presses in the future; which will result in excess machine power scrap.

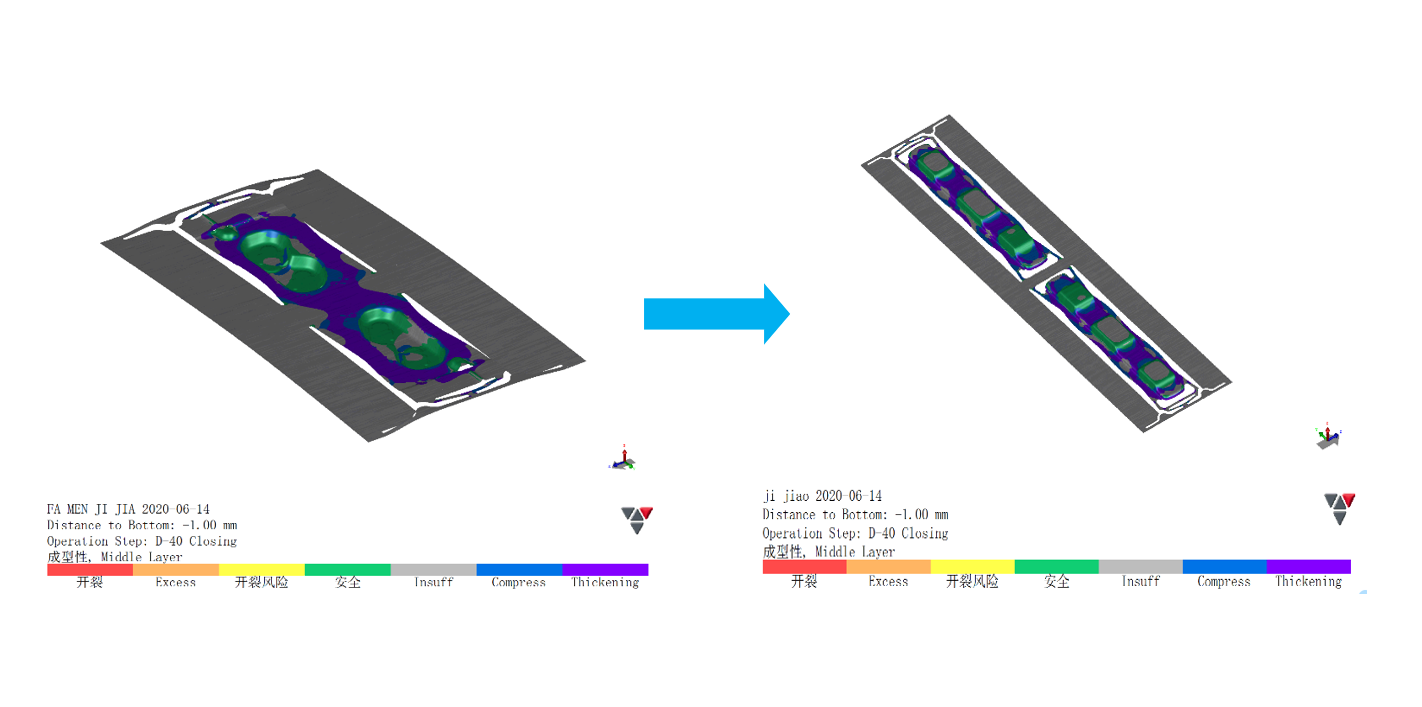

Therefore, it was decided to conduct a technical CAE formability analysis of the base and valve brackets in the common parts of multiple dies according to the one-hit-two scheme. The results show that the feeding stability, product connection reliability, and required forming force all meet the production conditions. The base foot and valve bracket can be changed from the original one-hit-one method to one-hit-two, so as to reduce the scrap of punching machine power and improve production efficiency.

■Analysis of advantages after improvement

| Improved production efficiency:one stamping produces two products, theoretically doubling production efficiency and shortening delivery cycle |

| Reduce cost:increased output per unit time, reduced equipment depreciation, labor and other amortized costs |

| Improved equipment utilization: reduce equipment idle time and give full play to equipment capacity |

| Floor space advantage: compared with two one-out-one dies, one-hit-two parts occupy less production space |

■Cost-effectiveness comparison

Cost comparison:

| One-hit-one part: low initial investment and low maintenance cost | one hit two parts: high initial investment and high maintenance cost |

Benefit comparison:

| One-hit-one part: low production efficiency and high unit cost | One-hit-two parts: high production efficiency and low unit cost |

■Issues and Solutions

(1) Continuous feeding stability

The dual-strip layout (two-out) requires nearly double the width compared to single-strip (one-out) production, necessitating special attention to layout stability and sufficient strip strength. Comprehensive CAE analysis should be conducted in advance to evaluate material collection issues and prevent material scrap caused by excessive feeding pitch.

(2) Solution to die balance

Whether the die force is balanced, the arrangement of nitrogen springs and ordinary springs, to ensure the quality of product molding, force, etc.

■Refinement and summary of technology and experience

(1) Tearing is required before stretching to ensure that the material can flow during the stretching process;

(2) At least 3 connecting points are required to ensure the balance of feeding.

■Refinement and summary of technology and experience

(1) Tearing is required before stretching to ensure that the material can flow during the stretching process;

(2) At least 3 connecting points are required to ensure the balance of feeding.

content is empty!

content is empty!

ZHUHAI GREE DAIKIN PRECISION MOLD CO., LTD.