Views: 0 Author: Site Editor Publish Time: 2025-05-15 Origin: Site

Stamping dies are indispensable in modern manufacturing, serving as the backbone for producing precision components across industries like automotive, aerospace, and consumer electronics. According to industry reports, over 60% of metal components in automotive manufacturing rely on stamping dies, highlighting their critical role in cost efficiency and product quality. Poorly designed dies can lead to defects such as cracks, wrinkles, or dimensional inaccuracies, increasing scrap rates by up to 15% and inflating production costs.

Stamping die manufacturing involves a systematic process that integrates design, material selection, precision machining, and advanced technologies like CAE simulation and DFM analysis to ensure high-quality, cost-effective production.

This article delves into the intricacies of die manufacturing, exploring key processes such as CAE-driven design optimization, high-precision machining, and emerging trends like intelligent manufacturing. We will also examine how industry leaders leverage cutting-edge technologies to maintain competitive advantages.

Stamping dies serve as the cornerstone of modern manufacturing, enabling mass production of precision components across industries like automotive, aerospace, and consumer electronics while optimizing cost efficiency and material utilization.

Stamping dies are engineered to transform flat metal sheets into complex geometries with micron-level accuracy. In automotive manufacturing, over 70% of structural components, including body panels, brackets, and engine parts, rely on stamping dies. The process ensures repeatability for high-volume outputs—progressive dies, for instance, can produce 1,000+ parts per hour with tolerances as tight as ±0.01mm. This efficiency is critical for industries requiring large-scale production, such as EV battery enclosures and appliance housings.

The shift toward lightweight materials, such as high-strength steel (HSS) and aluminum alloys, demands dies with enhanced durability and precision. Stamping dies enable the forming of ultra-thin components (e.g., 0.6mm-thick EV battery trays) while maintaining structural integrity, reducing vehicle weight by 20–30%. Dies also minimize material waste through optimized nesting designs, achieving 95%+ material utilization rates—critical for sustainability goals.

Modern stamping dies integrate advanced technologies to address evolving industry demands:

CAE Simulation: Tools like AutoForm predict material flow, thinning risks, and springback, reducing trial iterations by 50% and cutting development costs by 20,000–50,000 per project.

AI-Driven Design: Generative algorithms optimize die structures for weight reduction (e.g., 22% lighter dies) without compromising strength.

Surface Engineering: Techniques like TD coating and electropolishing enhance die lifespan by 3×, critical for stamping corrosion-resistant materials like stainless steel.

While initial die fabrication costs are high (50,000–500,000 depending on complexity), their long-term ROI is unmatched. A single progressive die can produce 5+ million parts before requiring maintenance, with per-part costs dropping to <$0.10 at scale. Industries like automotive save 15–20% in assembly costs due to stamped parts' consistent fitment.

Cost-Saving Strategies:

Modular Dies: Allow quick reconfiguration for multiple part designs, reducing tooling expenses by 40%.

Predictive Maintenance: IoT sensors detect micro-cracks 200+ hours before failure, slashing unplanned downtime by 60%.

Automotive: Dies for HSS components require hardened tool steels (e.g., D2 or M2) with nitrided surfaces (≥60 HRC) to withstand 1,500+ MPa tensile stresses.

Electronics: Micro-stamping dies produce connectors with 0.1mm pitch tolerances, enabled by EDM (electrical discharge machining) precision.

Medical Devices: Mirror-finish dies (via electropolishing) ensure biocompatibility and burr-free edges for surgical tools.

Emerging trends are reshaping die manufacturing:

Digital Twins: Virtual replicas of dies simulate real-world performance, optimizing parameters like press speed (≤20 SPM) and clamping force.

Sustainable Practices: Recyclable tool steels and MQL (minimum quantity lubrication) systems reduce CO₂ emissions by 35%.

Hybrid Dies: Combine carbon fiber-reinforced polymers with steel cores for 40% weight reduction and faster thermal response.

Stamping die manufacturing integrates advanced design methodologies, precision machining technologies, and rigorous quality control to produce high-performance tools capable of shaping complex components with micron-level accuracy.

The process begins with CAE (Computer-Aided Engineering) simulation to optimize die geometry and predict material behavior during forming. Tools like AutoForm and ANSYS Workbench analyze stress distribution, thinning risks, and springback effects, reducing trial iterations by 50% and shortening development cycles from 12 weeks to 6 weeks.

Design for Manufacturing (DFM) principles are critical at this stage. Engineers validate:

Minimum bend radii (≥2× material thickness for aluminum).

Hole spacing (≥1.5× diameter to avoid deformation).

Draft angles (≥1° for smooth part ejection).

A case study on automotive fender dies demonstrated how combining CAE and DFM reduced material waste by 18% and extended die lifespan by 30% through optimized cooling channel design.

Tool steels dominate die manufacturing due to their wear resistance and thermal stability. Common materials include:

AISI D2: High chromium content (12%) for abrasion resistance, hardness up to 62 HRC.

AISI O1: Oil-hardened steel with superior machinability for intricate geometries.

Carbide Inserts: Used in high-wear areas like blanking edges, extending lifespan by 3×.

Material preprocessing involves:

Laser Cutting: Prepares blanks with ±0.05mm accuracy.

Heat Treatment: Vacuum quenching ensures uniform hardness (e.g., 60–62 HRC).

CNC Machining: 5-axis CNC mills achieve complex geometries (e.g., undercuts, tapered walls) with surface roughness ≤Ra 0.4μm and flatness within ±2μm. For instance, smartphone chassis dies require 20+ hours of precision milling to meet ±2μm tolerances.

Electrical Discharge Machining (EDM): Ideal for micro-features like 0.1mm pitch connectors in electronics dies. Wire EDM cuts hardened steels with ±0.005mm accuracy, critical for aerospace components.

Additive Manufacturing: Conformal cooling channels, printed via laser powder bed fusion, reduce cycle times by 25% and warpage by 12%.

TD Coating: A vapor deposition process increases abrasion resistance by 3×, ideal for dies handling stainless steel.

Electropolishing: Reduces friction by 40% in deep-drawing applications, minimizing galling.

Nitriding: Surface hardening (to 1,200–1,500 HV) extends lifespan in high-volume production (e.g., 500,000+ cycles).

In-Process Monitoring: IoT sensors track parameters like press tonnage (800–2,500 tons) and ram speed (≤20 SPM), maintaining ±1% part consistency. Vibration sensors detect micro-cracks 200+ hours before failure, cutting unplanned downtime by 60%.

Post-Process Inspection:

Coordinate Measuring Machines (CMMs) verify tolerances (e.g., ±0.01mm).

3D scanning compares finished dies to CAD models, identifying deviations >0.02mm.

Recyclable Tool Steels: Reduce CO₂ emissions by 35% per die.

AI-Driven Optimization: Generative algorithms design lightweight dies with 22% less material while maintaining rigidity.

Hybrid Dies: Combine carbon fiber-reinforced polymers with steel cores for 40% weight reduction and faster thermal response.

Process | Tolerance | Cycle Time | Cost Efficiency |

|---|---|---|---|

5-Axis CNC Machining | ±2μm | 20+ hours | High |

Laser Cutting | ±0.05mm | 5–10 min | Moderate |

EDM | ±0.005mm | 15+ hours | High |

Additive Manufacturing | ±0.1mm | 8–12 hours | Moderate |

Key Metrics Comparison

By integrating these technologies, manufacturers achieve 30–50% faster time-to-market and 20% lower per-part costs in high-volume production.

High-precision die production relies on cutting-edge technologies such as multi-axis CNC machining, AI-driven process optimization, advanced surface engineering, and IoT-enabled quality control to achieve sub-micron tolerances, extended tool lifespan, and seamless integration with Industry 4.0 workflows.

(1) 5-Axis CNC Machining

5-axis CNC mills enable the fabrication of complex geometries (e.g., undercuts, tapered walls) with tolerances as tight as ±2μm and surface roughness ≤Ra 0.4μm. For example, smartphone chassis dies require 20+ hours of uninterrupted milling to achieve flatness within ±2μm—critical for ensuring seamless assembly of components like camera modules.

(2) Electrical Discharge Machining (EDM)

Wire EDM is indispensable for micro-features in hardened tool steels, such as 0.1mm pitch connectors for electronics dies. With positional accuracy of ±0.005mm, EDM minimizes thermal distortion, achieving edge sharpness <0.01mm radius.

(3) Additive Manufacturing (AM)

Laser powder bed fusion (LPBF) prints conformal cooling channels within dies, reducing cycle times by 25% and thermal warpage by 12%. A case study on automotive bumper dies showed AM-integrated cooling improved dimensional stability by 18% compared to traditional drilled channels.

(1) TD Coating

Thermal diffusion coating deposits a 5–15μm carbide layer (e.g., vanadium carbide) on die surfaces, increasing abrasion resistance by 3×. Dies for stainless steel stamping achieve 500,000+ cycles without rework, even under stresses exceeding 1,500 MPa.

(2) Electropolishing

This electrochemical process reduces surface roughness to Ra 0.1μm, cutting friction by 40% in deep-drawing applications. For medical device dies, electropolishing ensures burr-free edges and biocompatibility compliance.

(3) Plasma Nitriding

Surface hardening via nitrogen ion bombardment achieves case depths of 0.1–0.3mm and microhardness up to 1,200 HV, extending lifespan for high-volume production of aluminum alloy components.

(1) Generative Design

AI algorithms optimize die structures for weight reduction (e.g., 22% lighter) while maintaining rigidity. A generative-designed progressive die for automotive brackets reduced material costs by $15,000 and energy consumption by 30%.

(2) Predictive Maintenance

IoT sensors monitor real-time parameters like vibration (≤5µm displacement) and temperature (20–120°C). Machine learning models predict tool wear 200+ hours in advance, slashing unplanned downtime by 60%.

(3) Digital Twin Simulation

Virtual replicas of dies simulate real-world performance under varying conditions:

Press Speed: Optimized to ≤20 strokes per minute (SPM) to balance productivity and part quality.

Clamping Force: Adjusted between 800–2,500 tons to prevent over-stressing materials.

(1) In-Line Metrology

Laser scanners and CMMs (Coordinate Measuring Machines) perform 100% inspection of critical dimensions, such as:

Bend Angles: ±0.1° accuracy for automotive brackets.

Hole Positions: ±0.02mm for electronics connector dies.

(2) Adaptive Machining

Closed-loop CNC systems adjust feeds and speeds in real time based on tool wear data. For example, a 5-axis mill cutting hardened D2 steel automatically reduces spindle speed by 15% when tool deflection exceeds 2μm, maintaining tolerances.

(3) Energy-Efficient Processes

Minimum Quantity Lubrication (MQL) systems reduce coolant usage by 90%, while hybrid dies (carbon fiber + steel cores) lower energy consumption by 25% during thermal cycling.

(1) Automotive

Hot Stamping Dies: Water-cooled channels form ultra-high-strength steel (UHSS) components with tensile strengths >2,000 MPa.

Hydroforming Tools: Achieve complex tubular shapes with wall thickness uniformity ≥98%.

(2) Electronics

Micro-Stamping Dies: EDM-cut tungsten carbide inserts produce connectors with 0.05mm tolerance.

Vacuum-Assisted Forming: Eliminates air entrapment during thin-film metal forming (e.g., 0.2mm-thick EMI shields).

(3) Aerospace

Isothermal Forging Dies: Maintain ±5°C temperature uniformity for titanium alloy components.

Superfinishing: Diamond-turned surfaces achieve Ra 0.025μm for turbine blade dies.

The die manufacturing industry is undergoing a transformative shift driven by technological advancements and innovative practices. At Gree Daikin Mold (Zhuhai Gree Daikin Precision Mold), cutting-edge solutions are redefining traditional processes, setting new benchmarks for precision, efficiency, and sustainability. Below are key innovations spearheading this evolution, as demonstrated by Gree Daikin Mold's expertise and global client success stories:

Gree Daikin Mold leverages full 3D design and interference simulation to optimize mold performance before physical production begins. By simulating manipulator handling and mold assembly in a virtual environment, potential collisions or structural flaws are identified and resolved at the design stage. This approach minimizes trial-and-error during mold debugging, reducing lead times by up to 30%. For instance, their work on automotive stamping molds utilizes CAE (Computer-Aided Engineering) to analyze strip-forming processes, adjusting critical parameters like corner radii (R angles) to mitigate cracking risks—ensuring "one-trial success" for complex projects like automotive air conditioning corrugated panels.

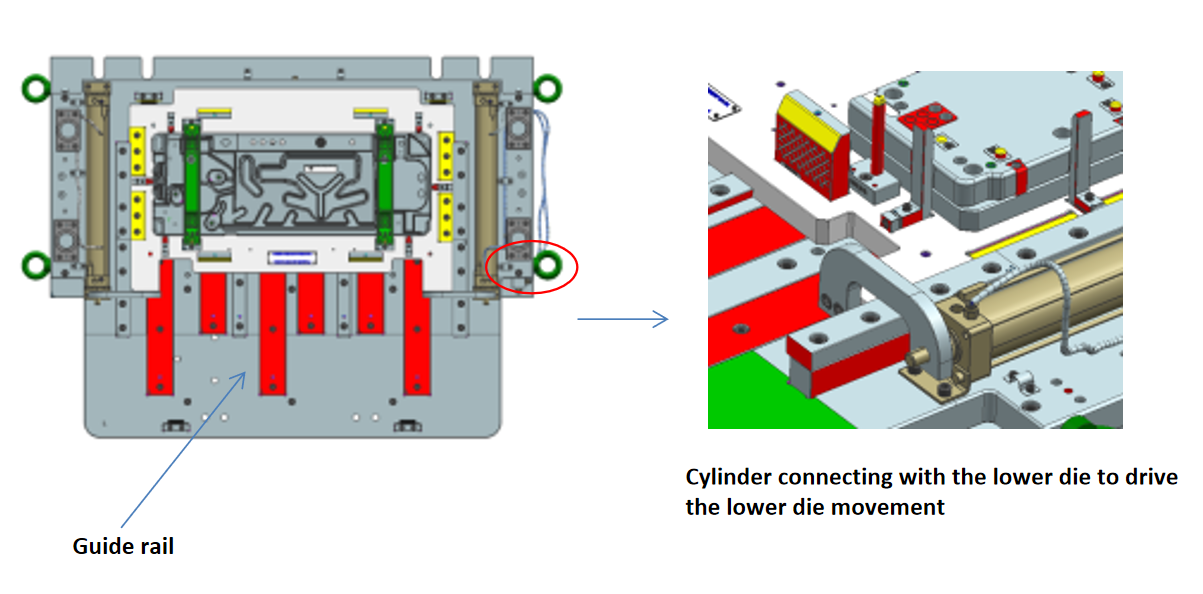

Gree Daikin Mold's nitrogen-gas spring technology exemplifies how structural innovation can streamline production. By redesigning molds from single-layer to double-layer movement, they reduced the front plate compression process from six steps to five for a U.S. appliance client, slashing tooling costs and cycle times. Similarly, their bottom-frame safety riveting technology integrates pneumatic cylinders with guided rail systems, enabling precise forward-backward motion for secure assembly without secondary operations. Such innovations align with industry demands for lightweight, multi-functional tooling.

Equipped with Makino and Mitsubishi CNC machines (accuracy ≤0.01mm) and an ERP-based tracking system, Gree Daikin Mold embodies smart manufacturing. Real-time monitoring of machining status via CAE/CAD/CAM/UG software ensures seamless coordination across design, production, and quality control. For example, their automated changeover technology allows multi-product molds to adapt swiftly to client specifications, boosting production efficiency by 40% for automotive and healthcare clients.

Gree Daikin Mold's collaborative Design for Manufacturability (DFM) approach bridges R&D and production. By partnering with clients during the DFM phase, they optimize product geometries for progressive die manufacturing, as seen in large-scale continuous molds for home appliance side panels. Material innovations also play a critical role: SGCD2 and PSGCD2-42N-Z08QV alloys are selected for high strength, corrosion resistance, and fatigue durability—key for precision components like steamer racks, where mirror-polished surfaces eliminate scratches and flow marks.

Through CAE-driven process consolidation and tool structure optimization, Gree Daikin Mold reduces material waste and energy consumption. Their ability to merge multiple stamping stages into fewer operations (e.g., progressive dies for office appliance samples) lowers labor costs by 25% while maintaining ISO-certified quality standards. Clients, including leading German automotive brands, attest to molds with extended service lives and precision tolerances, underscoring the economic and environmental benefits of sustainable tooling.

GreeDaikinMold's 150-member technical team combines expertise in automotive, healthcare, and consumer electronics tooling. Multilingual engineers and agile workflows enable rapid adaptation to diverse industry standards—from medical stamping molds requiring zero-defect surfaces to high-volume automotive dies demanding ultra-fast cycle times. This versatility positions Gree Daikin Mold as a leader in cross-sector innovation.

Looking ahead, the stamping die manufacturing sector will be shaped by five transformative trends, each offering opportunities for innovation and growth:

The integration of artificial intelligence (AI) and machine learning into CAD/CAE systems will further accelerate design optimization. AI algorithms can predict material behavior, recommend structural adjustments, and forecast tool wear, enabling proactive maintenance. For companies like Gree Daikin Mold, this means enhancing their 3D simulation frameworks to include real-time predictive analytics, reducing unplanned downtime and extending mold longevity.

Environmental regulations and ESG (Environmental, Social, and Governance) priorities will push manufacturers toward circular economy practices. Gree Daikin Mold's expertise in material efficiency (e.g., reducing scrap via CAE analysis) and energy-saving processes (e.g., multi-stage consolidation) positions it to lead in eco-conscious tooling. Future initiatives may include adopting recycled alloys, carbon-neutral machining, and closed-loop cooling systems to minimize environmental footprints.

As industries like electric vehicles (EVs) and smart appliances demand shorter product lifecycles, rapid tooling and modular mold systems will become critical. Gree Daikin Mold's automated changeover technology and collaborative DFM approach provide a blueprint for scalable customization. Investments in 5D printing (combining additive manufacturing with CNC machining) could further compress prototyping cycles from weeks to days.

Post-pandemic supply chain disruptions have spurred a shift toward regional manufacturing hubs. Gree Daikin Mold's global footprint—supported by multilingual teams and localized R&D centers—will be vital in serving clients who prioritize nearshoring. By establishing partnerships in key markets (e.g., Europe, North America, and Southeast Asia), Gree Daikin Mold can offer faster response times and mitigate geopolitical risks.

While automation advances, the human element remains irreplaceable. Gree Daikin Mold's 150-member technical team exemplifies how skilled engineers, equipped with AI-augmented tools, can push the boundaries of innovation. Upskilling programs in AI, IoT, and advanced materials science will ensure Gree Daikin Mold's workforce stays ahead of technological curves.

To maintain its leadership, GreeDaikinMold plans to:

Expand digital twin capabilities for end-to-end lifecycle management of molds.

Launch a green manufacturing initiative, targeting 40% reduction in energy use by 2030.

Forge alliances with tech providers to integrate IoT-enabled sensors into molds for real-time performance monitoring.

Double R&D investment in AI and material science, focusing on lightweight composites for EVs and aerospace.

The future of die manufacturing is one of convergence—where precision meets sustainability, digital tools amplify human expertise, and global challenges inspire localized solutions. Companies like Gree Daikin Mold, with their blend of technical mastery, agility, and visionary leadership, are poised to not only adapt to these changes but to define them. As industries from healthcare to renewable energy demand smarter, faster, and greener tooling solutions, Gree Daikin Mold's relentless innovation ensures it will remain at the forefront of this dynamic evolution.

content is empty!

content is empty!

ZHUHAI GREE DAIKIN PRECISION MOLD CO., LTD.