Views: 0 Author: Site Editor Publish Time: 2025-03-24 Origin: Site

The selection of appropriate materials for injection molds significantly impacts production efficiency, product quality, and overall manufacturing costs. This research explores the common materials used in injection mold manufacturing, their properties, applications, and challenges faced in the industry. As a leader in precision mold manufacturing, GDM (Zhuhai Gree Daikin Precision Mold Co., Ltd.) leverages advanced CAE technology and extensive experience to optimize material selection and mold design for various industries including automotive, home appliances, medical equipment, and more. This article provides an in-depth analysis of injection mold materials and their technological implications to help manufacturers make informed decisions.

The injection molding industry faces several critical challenges related to material selection and application:

Balancing durability and cost efficiency: High-performance mold materials often come with significant cost implications, creating a difficult trade-off between longevity and initial investment.

Thermal management issues: Different materials exhibit varying thermal conductivity properties, affecting cooling time, cycle efficiency, and part quality. Poor thermal management can lead to warping, sink marks, and extended production cycles.

Corrosion and wear resistance: Molds processing corrosive or abrasive materials require special considerations to prevent premature degradation and maintain dimensional accuracy over production runs.

Complex part geometries: Increasingly intricate product designs demand mold materials that can be precisely machined while maintaining structural integrity during the injection process.

Sustainability concerns: Traditional mold materials often have significant environmental footprints, with limited recyclability and energy-intensive production processes.

These challenges necessitate sophisticated material selection strategies and innovative approaches to mold design and manufacturing.

GDM has developed comprehensive technical solutions to address the challenges in mold material selection and application:

GDM employs a systematic approach to material selection that integrates CAE technology with decades of practical experience:

Advanced simulation technologies: Utilizing strength and tool life simulation analysis to predict potential issues like thin steel sections and cracking problems before manufacturing begins.

Material property database: GDM maintains an extensive database of material properties and performance characteristics based on real-world applications and testing.

Steel inspection protocols: Rigorous quality control measures include tensile strength testing, X-ray property analysis, and ultrasonic flow detection to ensure material consistency and integrity.

GDM has pioneered several innovative approaches to material utilization:

Hybrid material construction: Combining different steels in a single mold to optimize performance where needed while controlling costs in less critical areas.

Surface treatment technologies: Applying specialized coatings and treatments to enhance wear resistance, reduce friction, and improve release characteristics without changing the base material.

Precision machining optimization: GDM's advanced CNC equipment (including Makino and Mitsubishi machines) achieves machining accuracy up to 0.005mm, allowing for optimal material utilization and precision regardless of material hardness.

For high-demand applications like automotive cooling fans and medical devices (such as hemoperfusion cartridges), GDM implements material-specific design strategies:

Targeted reinforcement: Strategic reinforcement in high-stress areas while maintaining optimal material distribution throughout the mold.

Thermal management design: Integration of cooling channels and material selection to optimize thermal conductivity and cycle time.

Quality validation processes: Comprehensive testing protocols using German Zeiss CMM machines with measurement accuracy better than 0.003mm/2000mm to verify material performance.

The injection molding industry utilizes a variety of materials, each with distinct properties and applications:

Pre-hardened steel offers a good balance of machinability, wear resistance, and cost-effectiveness. These materials typically have hardness levels of 28-32 HRC and are widely used for large molds with moderate production volumes. P20 variations with improved polishability are preferred for optical parts and visible surfaces.

With hardness levels of 48-52 HRC, these steels offer excellent wear resistance and hot hardness, making them ideal for high-volume production and abrasive materials. H13 is particularly suitable for die-casting molds and injection molds for engineering plastics due to its thermal fatigue resistance.

Corrosion-resistant stainless steels are essential for processing corrosive plastics like PVC or for medical and food applications. Though more expensive and harder to machine, their resistance to rusting and pitting makes them invaluable for specific applications.

These high thermal conductivity materials significantly improve cooling efficiency in critical areas of the mold. Though expensive, beryllium copper inserts can dramatically reduce cycle times and improve part quality in areas prone to heat buildup.

For prototype tooling and short production runs, aluminum molds offer rapid machining, excellent thermal conductivity, and lower costs. Modern aluminum alloys with hardness up to 180 HB provide improved durability while maintaining thermal advantages.

These premium materials offer exceptional combinations of wear resistance, toughness, and dimensional stability for the most demanding applications where extended tool life is critical despite higher initial costs.

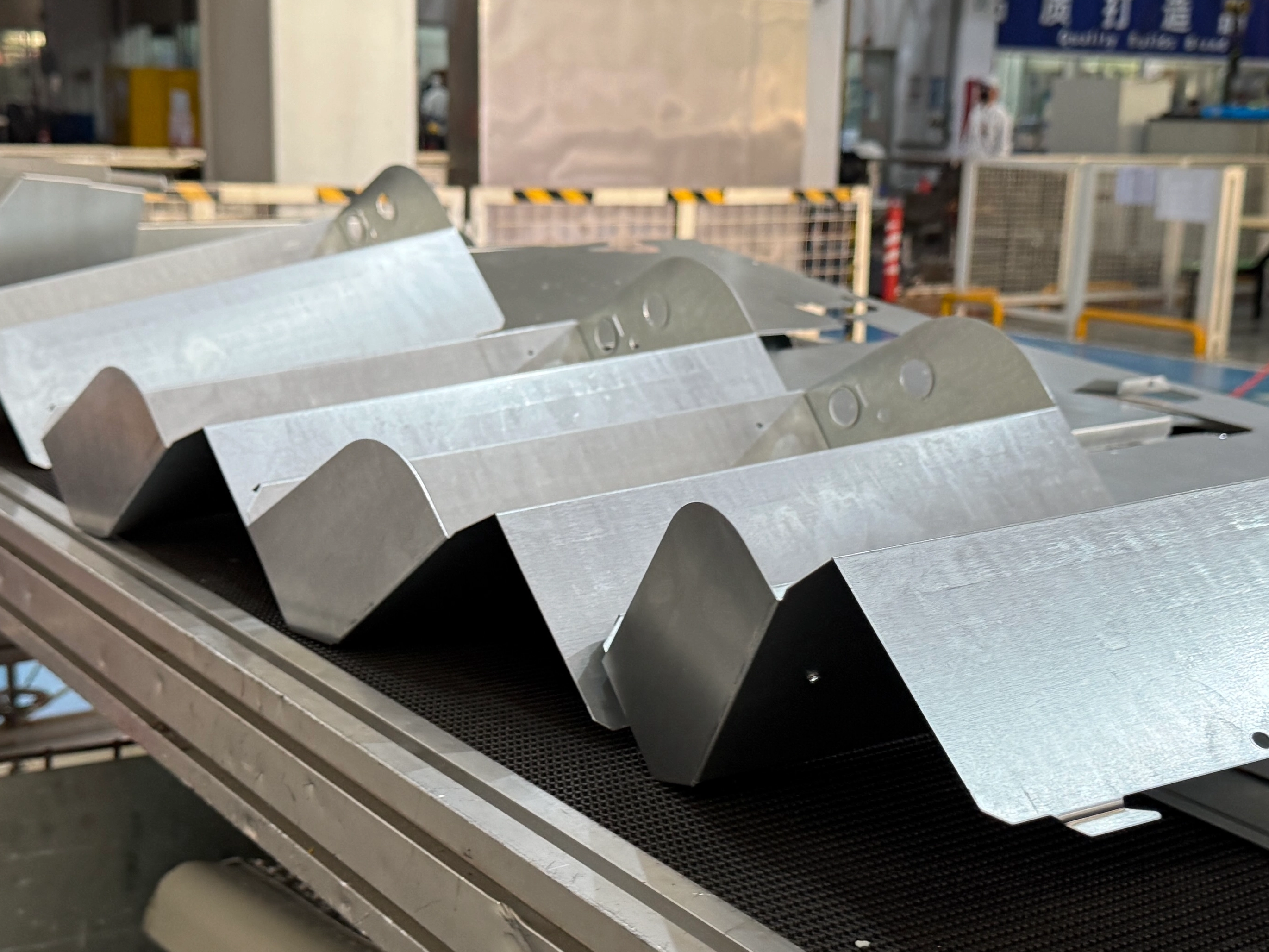

The most basic and widely used mold design consists of two plates (core and cavity) that separate along a single parting line. GDM employs these for simple parts with one primary parting direction, such as flat parts, containers, and basic housings. Their straightforward design offers cost-effectiveness and easier maintenance, making them ideal for high-volume production of uncomplicated parts.

These molds include an additional floating plate that allows the runner system to separate from the parts automatically. GDM utilizes this design for small parts requiring gate placement away from the parting line, such as medical components and precision electronics parts. The automatic separation of runners from parts eliminates the need for secondary operations, improving efficiency for high-volume production.

Featuring heated channels that keep plastic molten until injection into the cavity, these sophisticated molds eliminate runners, reducing waste and cycle times. GDM implements hot runner technology for high-volume production of consumer goods, automotive components, and premium parts where material waste reduction and cycle time improvement justify the higher initial investment.

These multi-level molds can produce twice or more parts per cycle compared to conventional molds. GDM designs stack molds for high-volume production of identical parts like bottle caps, containers, and medical components, significantly improving productivity without requiring larger injection machines.

Specialized molds with mechanical or hydraulic unscrewing mechanisms for producing threaded parts. GDM employs these for manufacturing bottle caps, plumbing fittings, and threaded medical components like the hemoperfusion cartridge cases. The precise engineering of these molds ensures accurate thread formation and reliable part ejection.

GDM incorporates recycled tool steel in appropriate applications, reducing environmental impact while maintaining performance specifications. These materials undergo rigorous quality testing to ensure they meet the same standards as virgin materials. The carbon footprint reduction can reach 70% compared to new steel production while maintaining 90-95% of original performance characteristics.

By implementing specialized surface treatments and precision engineering, GDM has extended the lifecycle of aluminum molds, making them viable for medium production runs. These molds require approximately 20% less energy to produce than steel equivalents and can be fully recycled at end-of-life, creating a significantly reduced environmental footprint throughout the product lifecycle.

GDM pioneers hybrid mold construction that combines durable tool steel in high-wear areas with more environmentally friendly materials elsewhere. This approach reduces the overall material footprint while maintaining performance where needed most. The modular design approach also allows for targeted repair and replacement of worn components rather than entire mold replacements.

For automotive applications, material selection directly impacts part precision, surface quality, and production efficiency. GDM's high-precision automotive cooling fan molds demonstrate how advanced material selection enables the production of components with strict dimensional tolerances affecting air volume and noise levels. The company's expertise in P20 and H13 steel applications allows for producing complex automotive parts with thin walls, tight tolerances, and excellent surface finishes essential for both functional and aesthetic components.

In home appliance manufacturing, GDM leverages its connection with Gree Electric Appliances to optimize material selection for durability and cost-efficiency. The mold materials must withstand high production volumes while maintaining dimensional stability for components that often have both mechanical and aesthetic requirements. GDM's implementation of specialized stainless steel grades for appliance components that contact water or food ensures both regulatory compliance and product longevity.

For medical applications like hemoperfusion cartridges, material selection is critical for maintaining biocompatibility and meeting regulatory requirements. GDM employs specialized stainless steel grades (such as 1.2316) that resist corrosion from sterilization processes while providing the high-precision capability needed for threaded components with sealing functions. The polishability of these materials also enables the optical clarity required for transparent medical components.

The electronics industry demands mold materials capable of producing components with increasingly fine details and tight tolerances. GDM's implementation of premium tool steels with enhanced wear resistance ensures consistent production of intricate connectors, housings, and structural components. The thermal management properties of selected materials directly impact the prevention of warpage in thin-walled electronic components, a critical factor in modern miniaturized devices.

GDM offers comprehensive support for a wide range of injection mold materials, leveraging its advanced equipment and extensive expertise:

Tool Steels: Complete processing capabilities for P20, H13, 1.2738, 420, and specialty grades using high-precision CNC equipment with accuracy up to 0.005mm.

Stainless Steels: Specialized machining processes for stainless steel grades including 1.2083 and 1.2316, with particular attention to surface finish and dimensional stability.

Copper Alloys: Precision machining and integration of beryllium copper components for thermal management optimization.

Aluminum Mold Bases: Rapid production of prototype and low-volume production molds using high-grade aluminum alloys.

Advanced Surface Treatments: Implementation of various coatings and treatments to enhance material performance characteristics including wear resistance, release properties, and corrosion protection.

GDM's technical capabilities extend beyond material processing to include comprehensive testing and validation, ensuring that selected materials perform optimally in the final application.

The injection mold material industry continues to face challenges that drive research and development:

High-performance mold materials often face trade-offs between durability, machinability, and cost. The increasing demand for complex part geometries with thin walls requires materials that can maintain tight tolerances while enduring high injection pressures. Additionally, sustainability requirements are creating pressure to develop more environmentally friendly options without sacrificing performance.

Research is advancing in several promising directions:

Advanced tool steels with improved thermal properties that combine wear resistance with better heat transfer capabilities.

Composite mold materials that integrate metal alloys with other materials to optimize performance characteristics in specific areas of the mold.

Additive manufacturing for conformal cooling channels within traditionally manufactured mold bases, creating hybrid solutions that maximize thermal efficiency.

Smart materials with embedded sensors that can provide real-time data on mold performance, wear, and maintenance needs.

GDM remains at the forefront of these developments, continuously investing in research and technology to provide customers with the most advanced material solutions for their injection molding needs.

The selection of appropriate injection mold materials remains a critical factor in achieving optimal production efficiency, part quality, and cost-effectiveness across industries. GDM's comprehensive approach to material selection, combined with advanced CAE technology and precision manufacturing capabilities, enables the delivery of high-performance molds tailored to specific customer requirements.

By continuing to innovate in material application and processing techniques, GDM helps customers navigate the complex landscape of injection mold materials, providing solutions that balance performance, durability, and cost-effectiveness. As the industry evolves, GDM's commitment to research and technological advancement ensures that customers benefit from the latest developments in material science and manufacturing technology.

The future of injection mold materials will likely see increasing specialization and customization, with materials selected and engineered for specific applications rather than general-purpose use. GDM's deep expertise and comprehensive capabilities position the company to lead this evolution, delivering precision molds that exceed customer expectations and advance the state of the art in injection molding technology.

ZHUHAI GREE DAIKIN PRECISION MOLD CO., LTD.