Views: 0 Author: Site Editor Publish Time: 2025-07-10 Origin: Site

You can make injection molds last less time by making mistakes. Some mistakes are picking the wrong injection mold material, not doing regular maintenance, or not following rules. These mistakes can make things cost more and lower the quality. Injection mold lifespan is important because strong molds help make many products. They also keep the quality the same. If molds do not last long, you need to replace them more often. This costs more money and can cause problems with the products. Watch for things that can make molds wear out faster. Check your maintenance routines to keep your molds working well and your products good.

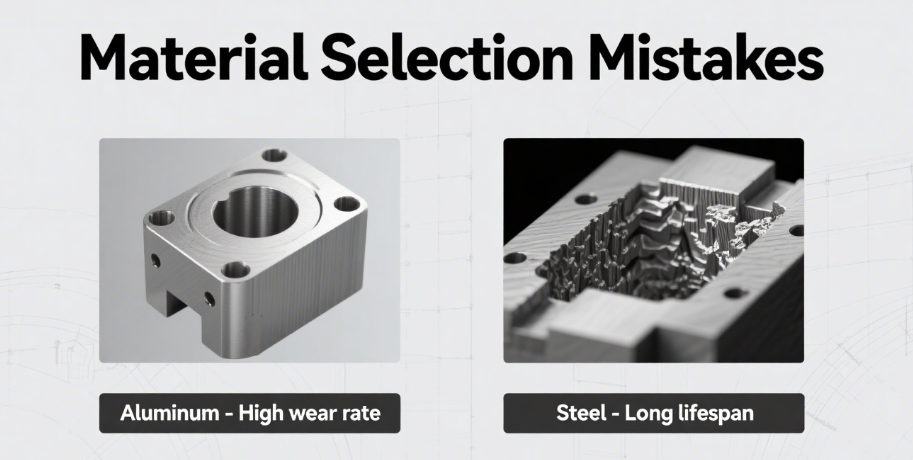

Pick the right mold materials like steel for long use. Do not mix materials that do not work well together. This helps stop damage.

Make sure molds have good cooling, venting, and draft angles. This lowers wear and makes it easier to take out parts.

Clean, oil, and check molds often to find problems early. This keeps molds working well.

Use the right machine settings and do not use very high heat. Do not hit molds too hard. This keeps molds safe from stress and breaking.

Keep molds in dry, cool places away from sun and dust. Write down details to stop rust and damage.

It is important to pick the right material for your injection mold. If you use aluminum for making many parts, the mold will wear out fast. Steel molds are better for making lots of products because they last longer. Aluminum molds are good for testing or making a few items, but they cannot handle long use. Using the wrong steel or tools makes the mold wear out early and work less well.

If you pick materials that cannot handle rough plastics, the mold will break down quickly.

If you use materials that rust or do not fit the work area, your mold will not last as long.

You need to care about the quality of your mold materials. Bad materials can make your molds have problems. These problems can make your products worse and cause you to fix or throw away parts.

Tip: Always check where your mold materials come from and if they are certified. Good materials help you make better products and stop delays.

Do not mix materials that do not work well together in your mold. Some materials can react and cause rust or damage. If you do not check, your mold can get ruined and not last long.

Bad material mixes can also hurt the cooling parts in your mold, making heat spread unevenly and causing bad results.

Always use mold materials that match the plastic and the work setting.

If you avoid these mistakes, your mold will last longer and work better. Good material choices help you make better products and have fewer problems.

You must think about cooling channels in every injection mold. If you forget this, the mold will not cool evenly. This makes the mold work badly and wear out faster.

Uneven cooling means longer wait times and more part mistakes.

If you do not plan the cooling channels well, the mold gets stressed and breaks sooner.

Good cooling channels can make things faster and better, but bad ones will not help.

Tip: Always check your cooling system to keep things steady and stop mold problems.

If you do not have enough venting, air and gas get trapped. This can ruin your parts. Bad venting can burn the mold or leave parts unfinished. It can even hurt the mold’s surface. You should look at vent spots and sizes to let gas out. Good venting keeps the mold safe and stops big repairs.

If you add too many tricky features, the mold can break early.

Sharp corners and thick spots make weak points that can crack.

Cooling channels too close to the top can let cracks show up fast.

Using different metals together can cause rust and make cracks worse.

EDM can leave a hard layer. If you do not clean it off, the mold gets weak and breaks.

Keep your mold design simple to stop these problems and have fewer mistakes.

If you do not use enough draft angles, it is hard to take parts out.

Too much rubbing wears out the mold faster.

This means more broken parts and longer waits.

Without draft angles, making parts takes longer and hurts the mold.

Good draft angles help parts come out easy and keep the mold safe.

Note: Draft angles are very important for making parts fast and stopping big problems.

You should not skip preventive maintenance if you want your injection mold to last. If you miss regular checks, the mold wears out faster and can break without warning. Not planning inspections lets small problems turn into big ones. These big problems make the mold last less time. Always look for cracks, rust, or loose parts. Checking these things helps you find damage early before it gets worse.

Doing regular maintenance keeps your mold working well and stops expensive delays.

Make a checklist for your inspections and use it every time. This habit will help your injection mold last longer and make better products.

Cleaning is very important for taking care of your mold. If you do not clean it or clean it wrong, you can hurt the mold’s surface. Dust, plastic bits, and leftover stuff can pile up and scratch the mold or block cooling channels. This buildup makes the mold not last as long and makes bad parts.

Use the right tools and cleaners for your mold.

Do not use strong chemicals that can damage the mold.

Clean all vents, runners, and cavities so nothing gets blocked.

Cleaning should always be part of your maintenance plan. When you keep the mold clean, you lower the chance of damage and help your mold last longer. Cleaning also makes it easier to check for early signs of wear.

Lubrication is needed to protect moving parts in your injection mold. If you do not use enough, friction goes up and the mold wears out fast. The mold and material rub together more, which causes more damage and a shorter life. Lubricants make a thin layer that keeps surfaces from rubbing. This layer cuts down friction and helps the mold last longer.

High pressure and heat make friction worse if you do not use enough lubrication.

Self-lubricating polymers can help where normal lubricants do not work.

Keeping friction low is important for making your mold last.

Tip: Always follow the manufacturer's rules for lubrication. Check moving parts when you inspect and add lubricant if needed. This easy step can help your injection mold last for years.

Good maintenance, like regular checks, cleaning, and lubrication, keeps your mold safe from harm and helps your work go smoothly. If you avoid these mistakes, your injection mold will last longer and cost less to use.

Making mistakes when using your injection mold can make it wear out fast. If you do not use the right settings, you can break the mold and stop work. You need to pay attention to how you use your machines. This helps you keep your mold safe and your work going.

If you run your mold too hot, it can get weak and break. Too much heat makes the mold tired and shortens its life. If you use low heat, the plastic does not fill the mold right. This can cause missing parts or bad shapes. Both hot and cold can hurt the mold and make it crack or bend. Always check the temperature and keep it in the safe range. This helps your mold last longer and work better.

Wrong settings for pressure, speed, or cooling can hurt your mold. If you use too much pressure, you can burn the parts or damage the mold’s edge. High pressure can also push the mold open and break it. If you use low pressure or slow speed, you can get dents or holes in your parts. Always check your settings before you start. Good settings help your mold last longer and make better parts.

Over striking happens when the mold closes or opens too hard. This can bend or break the ejector pins. It can also hurt the mold’s edge or even crack the mold. Too much force puts stress on moving parts and makes the mold wear out faster. You should set the clamping force to fit your mold. Gentle moves keep your mold safe and help it last longer.

If you run your mold too fast or too slow, it can cause problems. Fast cycles do not let the mold cool enough. This can make the parts bend or look bad. Slow cycles can make the mold too hot and tired. Both ways make the mold wear out faster. Always use the right cycle time for your mold. This helps your mold last longer and keeps your work smooth.

Not paying attention to warning signs is a big mistake. Small problems can turn into big ones if you ignore them. Watch for these signs:

Cracks in the mold

Deep scratches on important parts

Bent or broken ejector pins

Damage to the mold’s edge

Sticking or worn slides or lifters

Problems with the hot runner system

Flash, trouble opening or closing, stringing, galling, scratches, pitting, rust, and scoring

Check your mold every day for dirt, loose parts, or strange sounds. Look at your finished parts for problems like flash or missing spots. Each week, check the ejector system, clean vents, and look for leaks in cooling channels. Check the mold’s surface for rust or wear. If you ignore these signs, your mold can break, stop work, and cost a lot to fix. Many shops skip these checks and end up with big repairs and lost time. Checking your mold often and getting help when needed can stop problems and help your mold last longer.

Tip: Make daily and weekly checks a habit. Acting early keeps your mold working well and saves money.

Using your injection mold the right way helps it last longer. Avoiding these mistakes keeps your mold safe, lowers defects, and helps you get more use from your mold.

Environmental factors can shorten the life of your injection mold. You must control the storage and handling to protect your investment. If you ignore these risks, you will see a shorter lifespan and more repairs.

Humidity is a major threat to your mold. When you store molds in damp places, water in the air causes rust. Rust eats away at metal and weakens the mold. Always dry your mold completely before storage. Use gentle solvents and compressed air to remove moisture and debris. If you keep your mold dry, you protect its lifespan and keep it working longer.

Direct sunlight can damage your mold. UV rays break down some materials and cause surface cracks. Sunlight also heats the mold, which can lead to warping. Store your mold in a cool, shaded area. This keeps the mold safe and helps it last for its full life.

Dust and debris build up on your mold and cause problems. They scratch surfaces and block cooling channels. You should clean your mold after every use. Use soft brushes and safe cleaners. Regular cleaning stops buildup and helps you spot early signs of wear. This simple step extends the life of your mold.

Faulty storage conditions can ruin your mold. If you stack molds or leave them unprotected, you risk damage to delicate edges. Always use protective trays and store molds in a dry, clean place. Careful disassembly with the right tools prevents harm. Regular inspections help you find stress or wear before it gets worse.

Tip: Keep a log of inspections and require staff sign-offs. This builds accountability and ensures your mold gets the care it needs.

Best Practices for Storage and Handling:

Clean molds with gentle solvents and compressed air.

Dry molds fully before storage to prevent rust.

Disassemble and store parts in protective trays.

Inspect for wear and stress often.

Lubricate moving parts before storage.

Keep detailed logs of all maintenance and inspections.

By following these steps, you protect your mold from environmental damage and faulty storage conditions. Good storage habits help you get the most out of your mold’s lifespan and keep your production running smoothly.

You can help your injection mold last longer if you avoid mistakes and do regular care. Doing things like saving energy and recycling helps your work and keeps molds strong.

Cleaning, adding oil, and checking your mold often stop it from breaking.

Using lists to check your mold helps you find problems early and keep it working well.

Make a short checklist for each day. This easy step helps your mold work better and last longer.

You often skip regular maintenance. This mistake lets small problems grow. You may also use the wrong materials or ignore cleaning. These actions cause faster wear and more repairs.

You should inspect your molds daily for dirt or damage. Weekly checks help you find deeper issues. Use a checklist to make sure you do not miss any steps.

Yes, you can repair small cracks or worn spots if you catch them early. Quick action saves you money and keeps your mold working longer. Always fix problems as soon as you find them.

Store molds in a dry, cool place.

Clean and dry them before storage.

Use protective trays and keep a log of inspections.

Lubricate moving parts to prevent rust.

content is empty!

content is empty!

ZHUHAI GREE DAIKIN PRECISION MOLD CO., LTD.