1. Detailed Explanation of Technical Features for Pre-coated Metal (PCM) Dies

Material Selection: Use of high-hardness, high-wear-resistance materials (e.g., powder steel, carbide) to resist abrasion and maintain long-term smoothness.

Structural Design: Incorporation of large radii, optimized clearances, full-area blank holding, and minimized sliding to avoid stress concentration and reduce friction and squeezing.

Surface Treatment: Application of mirror polishing (Ra < 0.1μm) and ultra-hard, low-friction coatings (e.g., TD, DLC) to minimize friction and adhesion.

Production & Maintenance: Emphasis on high-precision machining, clean environments, and regular maintenance to ensure stable production of high-quality products.

In summary, sheet metal dies for processing pre-coated metals are no longer simple "iron-on-iron" contact tools. They are high-tech products integrating materials science, precision manufacturing, surface engineering, and lean design. Every feature is purposefully engineered to efficiently and accurately complete the forming task without damaging the exquisite surface. This results in significantly higher costs and greater technological sophistication for these dies compared to standard sheet-metal dies.

2. PLC-Controlled In-Die Tapping Technology

In-die tapping mechanisms can be either mechanical or servo motor-based. The tapping speed of mechanical systems is fixed and cannot be adjusted. When processing high-hardness materials, taps are prone to breakage. In contrast, the servo motor system only requires connection to a standard 220V 3-pin power supply. Its primary advantage is the ability to adjust the tapping speed. For instance, when tapping high-hardness materials like stainless steel, excessive speed can cause the tap to overheat and break, leading to unstable production. Therefore, adopting the servo motor method can mitigate this issue. For stainless steel stamping production at a press speed of 25 SPM, the recommended tapping speed is 350 RPM.

3. Common Automatic Scrap Discharge Mechanisms in Stamping Dies

Pneumatic Scrap Discharge: Features simple structural requirements and easy maintenance. It consists of a custom-made scrap chute, standard pneumatic components, and a pressurized air supply.

Conveyor Belt Type Scrap Discharge: Has specific requirements for the die structure, needing coordination between the upper and lower dies. All matching parts have standard models and require no secondary machining.

Knockout Pin Type Scrap Discharge: Features simple structural requirements, needing coordination between the upper and lower dies. It consists of a custom-made scrap chute + standard knockout pin components.

The above types can be manufactured according to customer requirements.

The advantages of automatic scrap discharge: Scrap is automatically ejected outside the die and collected by a dedicated scrap container, eliminating manual operation, enabling continuous, uninterrupted production, and improving production efficiency.

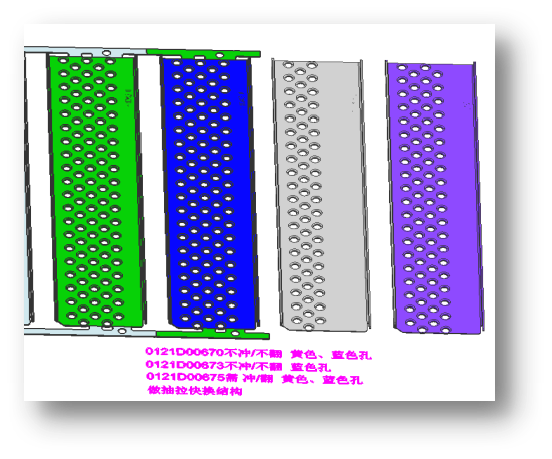

4. Automatic Tool Changeover for Multi-Product Technology with a Single Die

The style change mold is connected to the style change mechanism via a pneumatic cylinder, cascading multiple features requiring a style change. This allows for quick, automatic style change with a single click, eliminating manual disassembly or individual pull-out style changes. This improves style change efficiency and avoids operator error.

The pneumatic cylinder model is determined by calculating the pull-out force required to change the style, ensuring sufficient force to drive the style change mechanism. The high-precision mold style change guide structure ensures high stability during style changes.

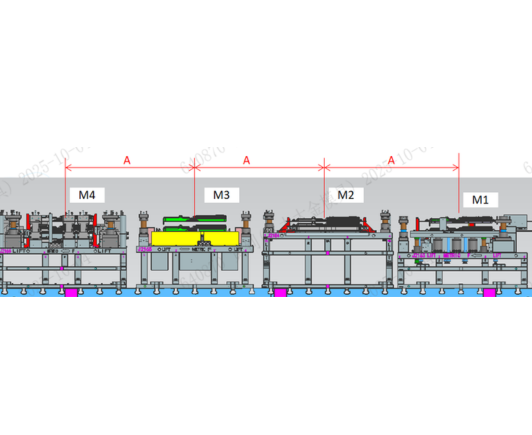

5. Detailed Features of 3D Mold Manufacturing Technology

1. Ensure that the spacing (A) value of each mold set is consistent and that the product center is aligned.

2. Ensure that the lower mold feed height (B) value remains consistent;

3. Ensure that the upper and lower molds do not interfere with each other during handling by the 3D robot in the open position.

GDM utilizes full 3D mold design, enabling robot simulation during the design phase to prevent mold interference and eliminate problems early in the design process.

6. Chassis safety riveting technology

Detailed explanation of the chassis safety riveting technology features:

The key to lower die movement is the design of a guide rail on the contact surface. A pneumatic cylinder is connected to the lower die, and an external drive mechanism drives the lower die in and out, ensuring die accuracy. The die's movable mechanism is machined to an accuracy of +/- 0.02mm.

7. Large-scale continuous tool-making technology for air-conditioning outdoor units

For large parts such as the left and right panels, partitions, and motor brackets of air conditioner outdoor units, the die length reaches 3500mm, and the structure is complex when making progressive dies. The dies have a dual-action upper, lower mold structure upper and lower die slider molding structure. Through CAE analysis and review with the customer during the Design for Functions and Measures (DFM) phase, we optimized the product and die structure to meet the requirements for making progressive dies.

content is empty!

content is empty!

ZHUHAI GREE DAIKIN PRECISION MOLD CO., LTD.