Views: 0 Author: Site Editor Publish Time: 2025-08-21 Origin: Site

Correct Methods for Zero-step difference in Injection Mold

In 2025, product aesthetics will transcend mere preference to become the paramount driver of consumer choice, demanding impeccable surface quality with zero defects. This new paradigm is catalyzing a fundamental shift to a "Mold-First" innovation strategy, where advanced mold engineering and precision manufacturing are the foundational drivers of aesthetic perfection. Cutting-edge capabilities—including AI-optimized mold flow simulation, nano-scale texturing, and innovative self-cleaning coatings—will be critical to achieving flawless finishes, from Class-A automotive surfaces to seamless, zero-gap consumer electronics. Concurrently, sustainability mandates will require that these pristine aesthetic standards be met even with high-content recycled materials, pushing the boundaries of material science and tooling precision to ensure no compromise in visual or tactile quality.

Mold manufacturer's process standard

As product appearance requirements become increasingly stringent, how can we achieve customer satisfaction? The criteria for injection mold production are also being refined, necessitating a comprehensive set of process standards that span from design to production. In particular, comprehensive standards are in place during the mold assembly process, and familiarity with mold structure and assembly techniques is crucial to ensuring mold production quality.

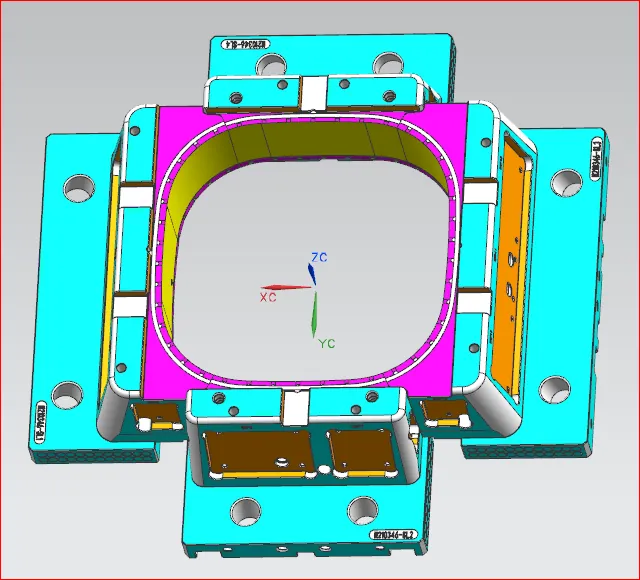

Part appearance is generally defined by the slider step difference. The most important thing is that the parts' appearance requirements must be determined from the beginning of the design. The slider step difference parting should be compared to avoid any joints in the appearance and joints caused by the inserts.

The part appearance-related slider insert’s machining must be processed with high requirements, and the processed parts must be inspected and qualified in all dimensions. For example, the mating surfaces between the sliders must be inspected and qualified.

Before assembly, verify the inspection reports for each slider to ensure they meet all dimensions. Ensure that all parts fit perfectly during assembly. Do not polish the mating surfaces; they must be aligned with the inspection data. Ensure that the surfaces formed by multiple sliders are aligned evenly. Do not polish the locating jaws. After mold assembly, the sliders can be reassembled and polished to eliminate any gaps.

The mold's quality dictates the product's appeal

Following mold fitting, appearance sliders must be assembled and subjected to coordinated finishing processes—including repair, polishing, step correction, and shut-off adjustment. This integrated approach is critical to achieving a flawless aesthetic appearance and ensuring ultimate customer satisfaction.

content is empty!

content is empty!

ZHUHAI GREE DAIKIN PRECISION MOLD CO., LTD.