Views: 0 Author: Site Editor Publish Time: 2025-08-29 Origin: Site

Chassis Stamping Die assembly: Overview of various compressor screw technologies

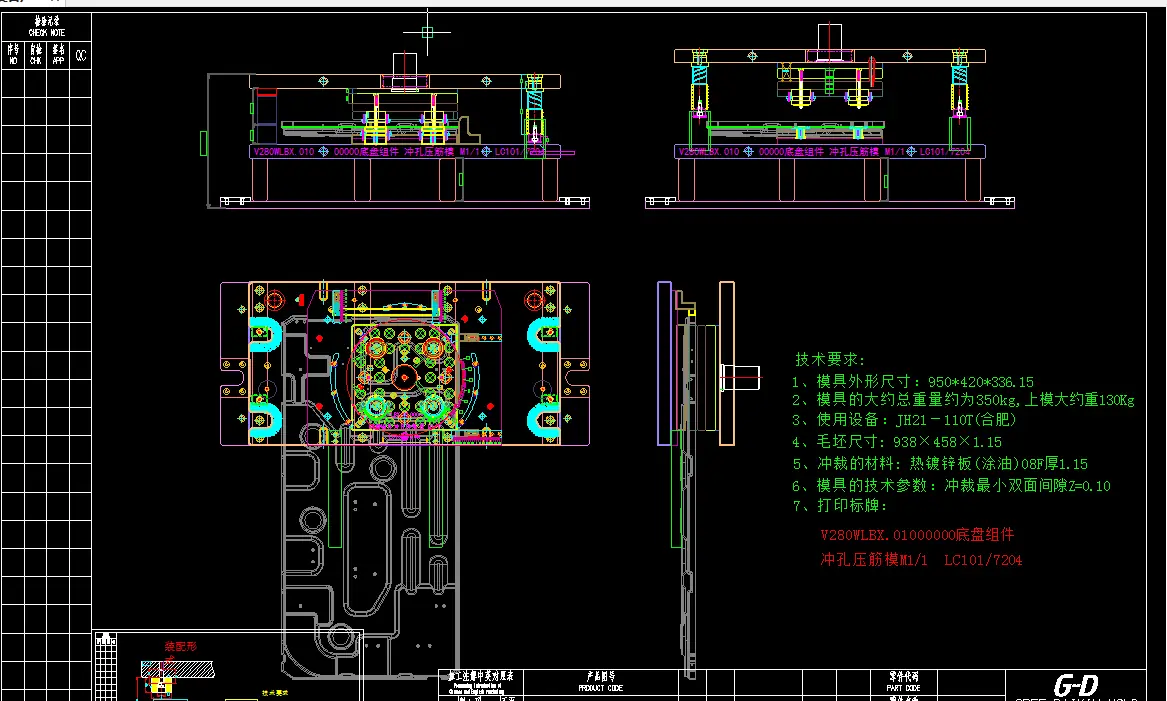

The sheet metal chassis products vary in dimensions. To optimize production efficiency and cost-effectiveness, die optimization is required to enable multi-model compatibility for punching and compression screw applications. Specifically, the LC101/7204 punching/ribbing die must accommodate all chassis components with compressor mounting holes measuring 148.5×148.5mm, featuring four Φ8.5mm diameter holes

One chassis component can achieve multiple chassis impacts

Stamping die structure diagram

Conventional tooling requires three or more sets of dies. In contrast, the current solution utilizes only one multi-station convertible die set to achieve multi-model compatibility, directly reducing stamping costs and maximizing corporate profitability.

Since 2009, we have been engaged in mold production, R&D, and service, integrating Gree Electric's business philosophy with Daikin Industries' Japanese standardized management model. Over the past 15 years, we have provided global clients across various industries with 18,000 sets of high-precision molds.

We have gathered top technical R&D talents in plastic injection molds and stamping molds, equipped with cutting-edge complete mold manufacturing and testing equipment, scientific and rigorous quality management systems, and premium mold steel materials from the USA, Germany, and Japan, ensuring full process control from CAE simulation to mass production. In recent years, the company has refined high-quality molds with exquisite craftsmanship, specializing in the design, manufacturing, and processing of various mold.

content is empty!

content is empty!

ZHUHAI GREE DAIKIN PRECISION MOLD CO., LTD.