| Availability: | |

|---|---|

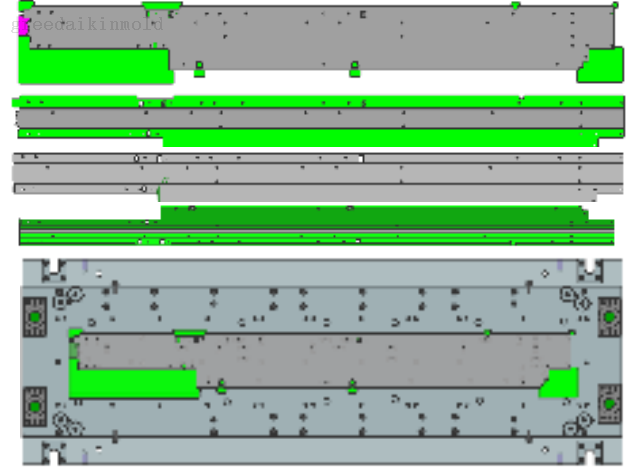

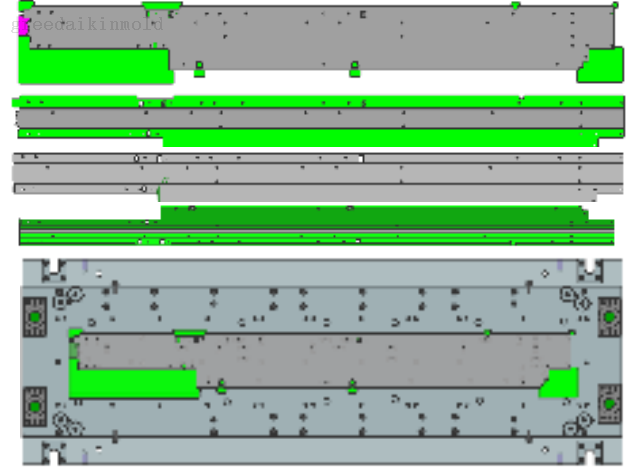

In the air conditioning manufacturing process, the bracket stamping die enables efficient production of diverse styles and specifications of modular components, meeting market demands for personalized and high-performance products. By 2025, as the global AC market rapidly shifts toward energy efficiency and smart technologies, innovative designs of such dies will significantly enhance production flexibility, shorten R&D cycles, and reduce costs.

GreeDaikinMold's high-precision machining ensures compatibility with next-gen AC systems, providing critical support for lightweight yet robust structural advancements. This drives the industry’s transition toward sustainable manufacturing and customization.

| (1)Tool structure design Adopt carbide insert anti-chipping design (SKH-51+TiAlN coating) |

| (2)Tool Production Efficiency Adopting a stepped unloading structure (punching force reduced by 40%) |

| (3)Tool accessories Adopting integrated standard processing, parts can be used in multiple dies to ensure the service life of the die |

| 1. Tool stability, reliability, and high quality |

| 2. Cost-effective solution |

| 3. On-time Delivery |

| 4. We guarantee a resolution within 24 hours |

| 5. strict quality control |

| 6. All dies are automotive |

We specialize in customized stamping dies for industries such as home appliances, automotive, and medical equipment—tailored to your precise specifications. Rest assured, we will deliver a die solution that meets your highest standards.

If you require home appliance bracket module accessory molds, our team offers expertise in cost-effective, high-precision manufacturing. Contact us today to discuss your project needs.

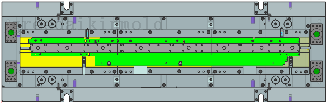

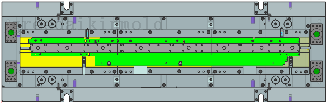

In the air conditioning manufacturing process, the bracket stamping die enables efficient production of diverse styles and specifications of modular components, meeting market demands for personalized and high-performance products. By 2025, as the global AC market rapidly shifts toward energy efficiency and smart technologies, innovative designs of such dies will significantly enhance production flexibility, shorten R&D cycles, and reduce costs.

GreeDaikinMold's high-precision machining ensures compatibility with next-gen AC systems, providing critical support for lightweight yet robust structural advancements. This drives the industry’s transition toward sustainable manufacturing and customization.

| (1)Tool structure design Adopt carbide insert anti-chipping design (SKH-51+TiAlN coating) |

| (2)Tool Production Efficiency Adopting a stepped unloading structure (punching force reduced by 40%) |

| (3)Tool accessories Adopting integrated standard processing, parts can be used in multiple dies to ensure the service life of the die |

| 1. Tool stability, reliability, and high quality |

| 2. Cost-effective solution |

| 3. On-time Delivery |

| 4. We guarantee a resolution within 24 hours |

| 5. strict quality control |

| 6. All dies are automotive |

We specialize in customized stamping dies for industries such as home appliances, automotive, and medical equipment—tailored to your precise specifications. Rest assured, we will deliver a die solution that meets your highest standards.

If you require home appliance bracket module accessory molds, our team offers expertise in cost-effective, high-precision manufacturing. Contact us today to discuss your project needs.

ZHUHAI GREE DAIKIN PRECISION MOLD CO., LTD.