Views: 0 Author: Site Editor Publish Time: 2025-07-21 Origin: Site

You use digital inspection technologies to make molds more accurate. Precision is important in every step, from design to molding. Smart molds have sensors that check temperature, pressure, and flow. These sensors give real-time data. This helps with maintenance and keeps the process steady. AI inspection technology finds defects and improves production. Digital twins and cloud analytics help you predict problems. They also help keep accuracy high. These tools lower errors in mold inspection. They also make each product more consistent.

Embedded sensors check important things for steady processes.

AI and digital twins make accuracy better and cut down defects.

Cloud analytics make mold inspection easier and improve quality.

Digital inspection tools such as 3D scanning, AI, and sensors help spot mold problems early. They also help keep the quality high.

Real-time monitoring and quick feedback let you fix problems fast. This saves time and cuts down on waste.

Digital twins and data analytics can predict problems before they happen. This makes things more accurate and lowers downtime.

Automated inspection systems help reduce mistakes made by people. They also make checks faster and help production go smoother.

Using these technologies helps lower costs and increase productivity. It also makes sure mold manufacturing is always accurate and steady.

You use digital inspection technologies to make molds better. These tools and inspection software check every part of the mold process. 3D scanning helps you see the mold’s shape exactly. CT scanning lets you look inside the mold without opening it. Computer vision and AI help you find problems fast. Non-destructive testing (NDT) checks if the mold is strong without breaking it. Digital twins are virtual copies of your mold. You can test changes on them before making real ones. ERP systems help you keep track of data and watch inspection steps from start to finish.

Digital inspection technologies give you feedback right away. This helps you make good choices. Inspection software lets you compare your mold to the design. This cuts down on mistakes and saves time.

You see digital inspection technologies at every step of making molds. These tools link design, production, and quality control with a digital thread. For example, you use virtual libraries and parametric design tools to add smart features to CAD files. Inspection software checks for mistakes before molding starts. AI-powered systems find defects and give ideas to fix them quickly.

Touch probe systems measure things fast and accurately during inspections.

Advanced CAD/CAM solutions, like TopSolid’Mold, connect design and making. They let you check drill depths and test tool paths.

Digital-native CNC platforms, such as Siemens Sinumerik One, help with automated inspection steps.

Portable fiber laser markers let you mark and check molds where you work, so you have less downtime.

You use these digital inspection technologies to check every step, from design to approval. This helps you find problems early and keep your molds correct.

You use 3D scanning to make molds very accurate. This technology captures the mold’s shape and size at each step. 3D scanners help you in many ways. You can measure how much material is left after machining. This helps you avoid mistakes and saves material. You can check if you need to change how you machine the mold. This saves time and money. After machining, you can see if the mold matches the CAD model. You can find gaps between mold parts during testing. This lets you fix them exactly. You can spot wear and changes after using the mold. This helps you repair it on time and keep products good. You can save 3D data for later or for design changes. 3D scanning gives faster and more exact data than old tools. This makes quality checks better and quicker.

You use 3D scanning for big or tricky mold parts. It helps you find wear and changes for repairs. It also helps you make reports to fix problems early. You can turn scanned data into CAD models to reverse engineer molds.

| 3D Scanning Tool | Application in Mold Manufacturing | Accuracy Specification |

|---|---|---|

| ZEISS T-SCAN Hawk 2 | High precision scanning, portable metrology-grade | 20 microns |

| Artec Micro desktop scanner | Small, intricate parts; automated scanning | 10 microns |

| NVision MobileScan | Injection mold inspection, reverse engineering | +/- 0.0005 inches (12.7 microns) |

3D scanning lets you check a 4-meter mold in 10 minutes. This gives fast, clear quality checks and lowers the cost to fix mistakes.

You use CT scanning to look inside molds without breaking them. This technology gives very exact inside and outside measurements. It finds problems that other ways miss. With CT scanning, you can spot holes, shrinkage, and missing fills inside the mold. You can measure inside and outside with ±0.010mm accuracy. You can check molds before making products to lower risks. You can study how materials move and cool to make things better. You can check molds and samples early to avoid big fixes later. You can save results to keep getting better.

CT scanning does not need to touch the mold or use coatings. It works well for hard shapes and groups of parts. But it costs more and takes longer to scan. For big parts, you might use white-light or laser scanning instead.

| Advantages of CT Scanning | Limitations of CT Scanning |

|---|---|

| Non-destructive 3D imaging | High equipment and service costs |

| Detects internal defects | Longer scan times (10 min–2 hrs) |

| Precise dimensional inspection | Less cost-effective for large parts |

| No line-of-sight restrictions | Requires advanced data processing |

CT scanning gives you a full 3D view inside and outside. This helps you solve problems fast and check products well.

You use computer vision and AI to check quality by machine. Cameras and smart software look for cracks, warping, or parts that do not fit. AI software helps you find problems faster and better than people. It can guess when machines might break, so you have less downtime. It looks at data to help you make better molds and improve how you work. It can test mold designs on a computer to find issues before you make them. It watches material flow live and spots things like air bubbles.

AI inspection systems show big improvements. For example, CNNs find over 90% of defects in injection molding. Custom CNNs find 99.86% of defects in casting.

| AI Model Type | Manufacturing Process | Defect Detection Accuracy |

|---|---|---|

| CNN | Injection Molding | >90% |

| Custom CNN | Casting Products | 99.86% |

AI-powered checks make work faster, cut mistakes, and keep mold quality high.

You use non-destructive testing (NDT) to check molds without hurting them. These methods help you find problems on the surface and inside.

| NDT Method | Principle / Technique | Application to Mold Integrity and Accuracy |

|---|---|---|

| Ultrasonic Testing (UT) | High-frequency sound waves detect internal and surface defects | Finds cracks, voids, and subsurface defects |

| Radiographic Testing (RT) | X-rays or gamma rays produce images of internal structure | Detects internal cracks and voids |

| Dye Penetrant Testing (PT) | Dye penetrates cracks, revealed by developer | Identifies surface-breaking defects |

| Magnetic Particle Testing (MT) | Detects surface and near-surface discontinuities in ferromagnetic materials | Quick detection of surface cracks |

| Eddy Current Testing (ET) | Electromagnetic induction detects surface cracks and measures thickness | Suitable for conductive molds |

You use these NDT ways to make sure molds are good. They help you check from design to finished part. This lowers the chance of problems in the final product.

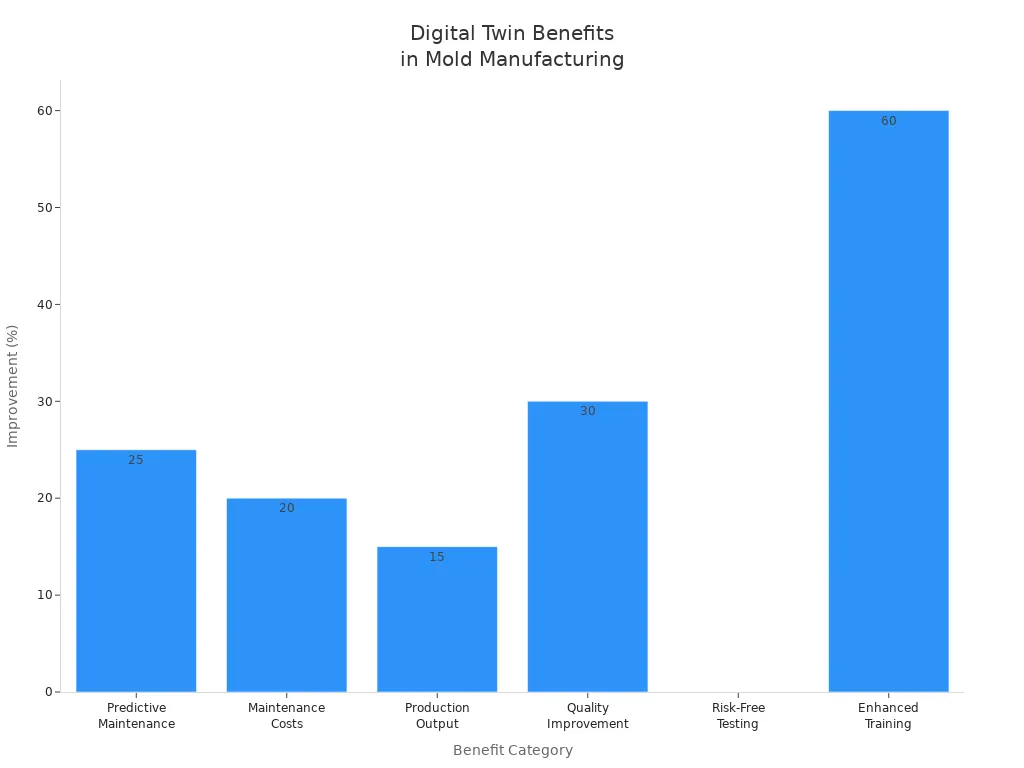

You use digital twins to make virtual copies of molds and lines. These digital models let you watch machines in real time. You can test changes and guess when to fix things. Digital twins help you spot problems early by watching vibration and heat. You can plan fixes before things break, cutting downtime by 25%. You can save about 20% on repairs with better planning. You can make more products by fixing slow spots, raising output by 15%. You can lower defect rates by 30% by catching problems early. You can test changes on the computer, saving weeks of work. You can train workers with these models, cutting training time by 60%.

Digital twins let software and machines talk to each other. You can change machine settings right away. This makes a feedback loop to keep making things better. It helps you test safely and work better with your team.

You use many tools to help with digital inspection. These include CMMs, robotic arms, automated lines, AGV carts, and ERP systems. CMMs, like bridge, gantry, and arm types, measure very exactly. They help with automatic checks. Robotic arms with laser scanners and probes measure important sizes. This makes sure molds match the design.

Automatic inspection systems, like machine vision and CMMs, stop human mistakes and speed up checks. In-line checks with cameras and sensors find problems right away. Optical systems check sizes without touching, down to tiny details. Inspection software works with these tools. It gives live quality checks, digital records, and tracks history.

Using these technologies, you make fewer mistakes, control the process better, and keep quality steady from start to finish.

Real-time monitoring helps you make molds better. In-mold sensors check things like pressure and temperature every time. Accelerometers also collect data during each cycle. Machine learning looks at this data right away. These models can spot problems as soon as they happen. You can see when something goes wrong. This lets you fix it before it gets worse.

Real-time monitoring helps you make quick choices. For example, accelerometer data shows each step in the process. You can change settings fast to keep things running well. A zero-defect system uses machine learning to guess if there will be problems. This system can be almost 99% right when finding issues. You keep your work good and waste less. Real-time monitoring gives you tools to keep quality high and make molds more accurate.

Tip: Real-time monitoring helps you find problems early. This saves money and keeps your work running smoothly.

You get fast feedback with digital inspection systems. These systems check parts right after the first ones are made. You see results right away, so you can find problems fast. Tooling experts look at the data and make changes quickly. You do not have to wait for slow reports or checks.

Digital inspection gives you quick feedback after molding.

You can find mistakes and fix them before making more parts.

Tooling engineers and designers work together to solve problems fast.

Fast feedback makes your work faster and parts better.

You keep making parts and do not stop for long.

When you use feedback right away, you make things more accurate. Each tool change helps you get better results. This way, you always make good molds.

You get better accuracy with data analytics and machine learning. Automated systems collect data at every step. Advanced analytics find patterns and show why problems happen. You can see where things go wrong and fix them.

Machine learning finds problems before they get big.

Predictive analytics helps you plan repairs and stop breakdowns.

Computer vision checks each part for mistakes very well.

Analytics help you make better choices faster.

Data-driven insights help you improve your supply chain and products.

You use these insights to make your process better. You lower mistakes, do less rework, and keep making good parts. Adaptive inspection tools with machine learning change as production changes. You get good results even if things are different. This way, you keep high accuracy and always make good molds.

Note: Data-driven insights help you keep getting better. You can watch your progress, see your results, and keep improving.

You get fewer defects with digital inspection technologies. Real-time monitoring helps you find problems early. Advanced analytics show issues before they grow bigger. Digital twins let you test your process before making real parts. This lowers scrap rates and keeps products within quality rules. Automated inspection tools, like optical measurement systems, catch even small mistakes. You keep your quality high and customers happy.

Digital inspection lets you spot defects quickly. This keeps your production line running well.

Digital inspection makes your work faster and more efficient. Real-time feedback lets you change settings right away. You do not waste time on slow manual checks. For example, companies save over 100 minutes each day by automating shot counting and reports. Managers save 20 minutes daily on data entry. These time savings help you make more parts in less time. You also get automatic tool IDs and alerts, so cycle times stay short. Even a one-second delay can cost money, so these tools protect your profits.

Real-time checks of cycle time, fill time, and pressure

Faster production cycles and better throughput

Improved communication between shifts and teams

Digital inspection technologies help you spend less money. Easy setup and integration mean you do not stop production for long. You cut downtime, scrap, and maintenance costs. Companies like Digital Moulds and BMW Group save money by keeping molds running and reducing waste. You also spend less on repairs because you find problems early. These savings help you stay ahead in the market.

You can see real results from digital inspection. A European airline maintenance team saved about $50 million by using digital inspection platforms. Manufacturers report 10-30% more throughput and up to 50% less machine downtime. Labor productivity goes up by 30%. In plastic pallet manufacturing, digital controls and simulations help you get higher precision and steady quality. These examples show digital inspection leads to better products, faster work, and lower costs.

When you use digital inspection, you see real improvements in every part of mold manufacturing.

Digital inspection technologies help you make molds more accurate. They also help you get better quality. You get feedback faster and have fewer mistakes. Production becomes quicker and smoother. More companies now use automation and AI to compete. They also use new inspection tools to do better work. To begin, you can:

Pick providers with ISO 9001 or other certifications.

Try modern tools like 3D scanning and automated checks.

Teach your team how to use new inspection ways.

Make clear inspection plans and write down steps.

Set up demos or trials for digital platforms.

Look at service quality, how flexible they are, and clear prices.

Doing these things helps you control quality better. It also keeps your business strong in a changing market.

You use digital inspection technologies to check molds with special tools. These tools include 3D scanning, non-destructive CT scanning, and automated metrology. They help you make molds more accurate and speed up checks. You can keep quality high from design to finished part.

Inspection technology gives you real-time data and exact measurements. You can find defects early and compare results with CAD models. This helps you make fewer mistakes and keep quality high during the whole process.

Automated metrology and inspection software help you check parts fast and the same way each time. You make fewer manual mistakes and save time. These tools help you track checks, keep records, and support every step from design to finished part.

Non-destructive CT scanning lets you see inside molds without breaking them. You can find hidden problems and measure inside features. This helps you make sure each part meets strict accuracy rules before you start molding.

You use digital inspection technologies to compare finished molds with the first designs. These tools help you check every step, from CAD to the last part. You find mistakes early, make things more accurate, and make sure the process meets all needs.

content is empty!

content is empty!

ZHUHAI GREE DAIKIN PRECISION MOLD CO., LTD.