| Availability: | |

|---|---|

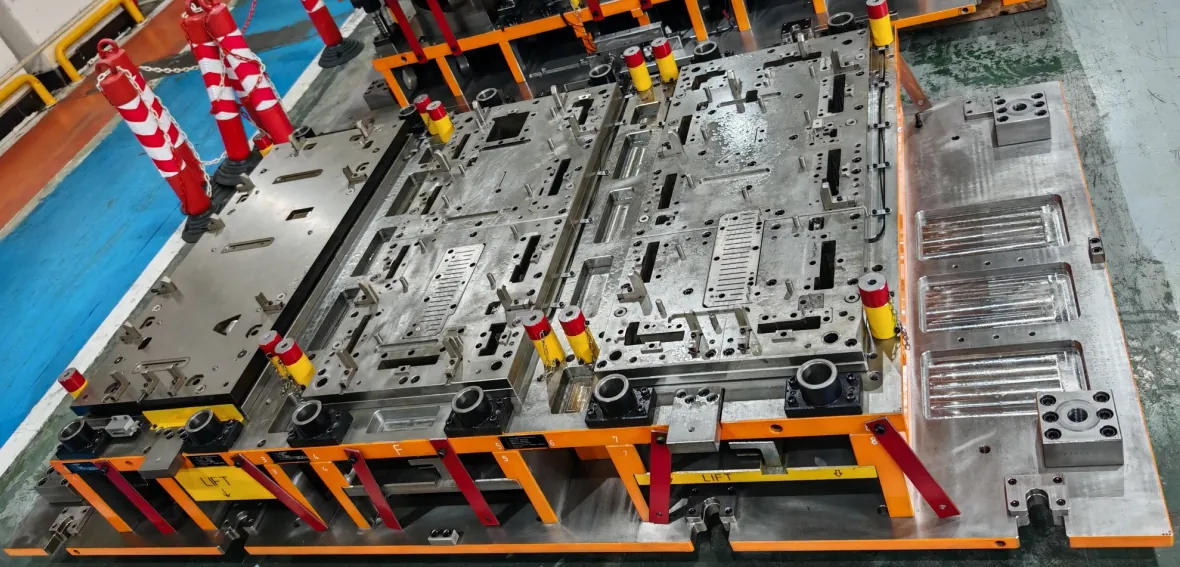

Air conditioning partition plate stamping die

The customization of air conditioning partition plate stamping dies has transcended mere tool manufacturing to become:

✅ The benchmark of precision manufacturing capability

✅ The pivotal lever for the green home appliance revolution

✅ A silicon-based counterweight rebalancing global industrial chains

Details as follows:

| Core and cavity steel: | SKH-51+TiAlN coating, 45#, D2, DC53, Gr12mo1v1, etc. |

| Standard parts | Panch, Misimi, etc. |

| Mold frame | self-made |

| Steel hardness | HRC60-62 |

| Material of stamping products | SGCC, SGCD2, DX56D, etc. |

| Number of cavities | 1X1 |

| Punching speed | 30SPM |

| Mold delivery time | 50-60 days |

| Mold life | 300,000 times |

| Mold structure design:Using full 3D parameterization and intelligent standard library design; |

| Mold production efficiency:Mold parts adopt standard quick-change disassembly structure, which is convenient for mold cost reduction, efficiency improvement and maintenance; |

| Mold accessories:Using integrated standard processing, physical vapor deposition CrAlSiN nano-coating (hardness HRC72) to ensure the service life of the mold. |

| Production tools:Mold production is automatic line 4X400T punching machine robot production |

| 30 years of experience in stampingl mold manufacturing |

| ISO 9001 certification |

| A technical R&D team of more than 100 people |

| Adopt nano-level CNC processing + EDM micro-hole technology |

| A scientific and rigorous quality management mechanism |

| Self-lubricating micro-hole structure design (oil-free stamping process) |

GreeDaikinMold 's business goal is "Exceeding Customer Expectations". It is committed to building a world-class precision mold enterprise and providing customers with comprehensive mold solutions.

Air conditioning partition plate stamping die

The customization of air conditioning partition plate stamping dies has transcended mere tool manufacturing to become:

✅ The benchmark of precision manufacturing capability

✅ The pivotal lever for the green home appliance revolution

✅ A silicon-based counterweight rebalancing global industrial chains

Details as follows:

| Core and cavity steel: | SKH-51+TiAlN coating, 45#, D2, DC53, Gr12mo1v1, etc. |

| Standard parts | Panch, Misimi, etc. |

| Mold frame | self-made |

| Steel hardness | HRC60-62 |

| Material of stamping products | SGCC, SGCD2, DX56D, etc. |

| Number of cavities | 1X1 |

| Punching speed | 30SPM |

| Mold delivery time | 50-60 days |

| Mold life | 300,000 times |

| Mold structure design:Using full 3D parameterization and intelligent standard library design; |

| Mold production efficiency:Mold parts adopt standard quick-change disassembly structure, which is convenient for mold cost reduction, efficiency improvement and maintenance; |

| Mold accessories:Using integrated standard processing, physical vapor deposition CrAlSiN nano-coating (hardness HRC72) to ensure the service life of the mold. |

| Production tools:Mold production is automatic line 4X400T punching machine robot production |

| 30 years of experience in stampingl mold manufacturing |

| ISO 9001 certification |

| A technical R&D team of more than 100 people |

| Adopt nano-level CNC processing + EDM micro-hole technology |

| A scientific and rigorous quality management mechanism |

| Self-lubricating micro-hole structure design (oil-free stamping process) |

GreeDaikinMold 's business goal is "Exceeding Customer Expectations". It is committed to building a world-class precision mold enterprise and providing customers with comprehensive mold solutions.

content is empty!

ZHUHAI GREE DAIKIN PRECISION MOLD CO., LTD.