| Availability: | |

|---|---|

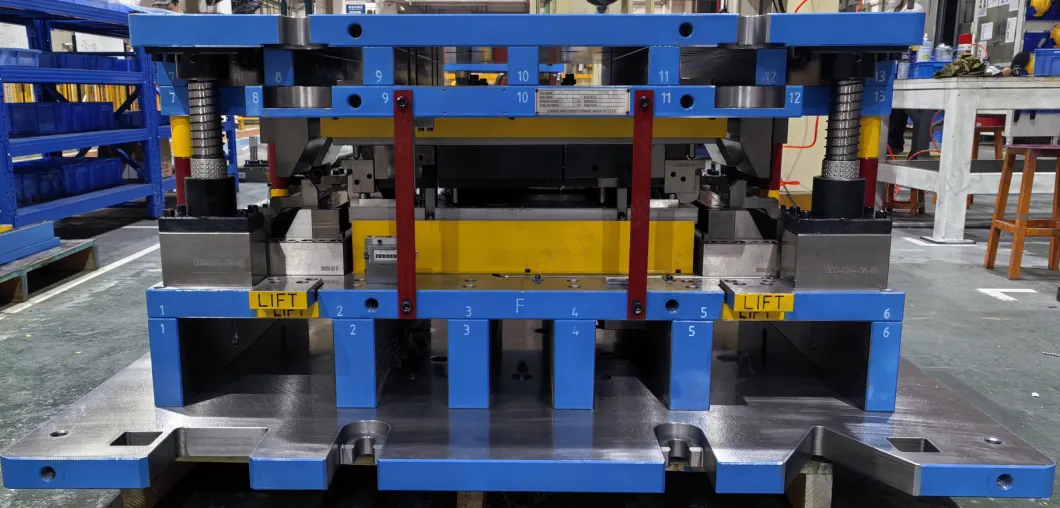

Air conditioner Front Plate Stamping Die

Application Scenario: Used for mass stamping of front plates of indoor air conditioners, compatible with wall-mounted and cabinet-type models of various sizes, capable of processing ABS, HIPS, and other plastic sheets.

The detailed information of the Front Plate Stamping Die is as follows:

| Using full 3D modularization and precision standard library design; |

| Mold parts use a quick-change disassembly structure to facilitate cleaning and maintenance of internal components. |

| Using integrated standard processing, parts can be used in multiple molds to ensure the service life of the tool. |

| Mold production is an automatic line 4X400T punching machine robot production. |

| 1. Smart sensing mold system optimizes processes via data feedback. |

| 2. CAE algorithm predicts forming defects (accuracy > 95%) |

| 3. Reduce the secondary assembly process, and improve the yield rate to 98.6% |

| 4. Adopt nano-level CNC processing + EDM micro-hole technology |

| 5. Tight quality checks guarantee consistent, defect-free mold output |

| 6. Self-lubricating micro-hole structure design (oil-free stamping process). |

GreeDaikinMold holds multiple certifications, including ISO certification and AEO Advanced Customs Certification. The AEO Advanced Customs Certification has brought significant convenience to our company's import and export operations. Holding this certification enables us to enjoy various preferential policies in customs trade, such as lower inspection rates and priority in customs clearance procedures. These advantages can effectively shorten the customs clearance time of goods and ensure on-time fulfillment of customer delivery deadlines.

Air conditioner Front Plate Stamping Die

Application Scenario: Used for mass stamping of front plates of indoor air conditioners, compatible with wall-mounted and cabinet-type models of various sizes, capable of processing ABS, HIPS, and other plastic sheets.

The detailed information of the Front Plate Stamping Die is as follows:

| Using full 3D modularization and precision standard library design; |

| Mold parts use a quick-change disassembly structure to facilitate cleaning and maintenance of internal components. |

| Using integrated standard processing, parts can be used in multiple molds to ensure the service life of the tool. |

| Mold production is an automatic line 4X400T punching machine robot production. |

| 1. Smart sensing mold system optimizes processes via data feedback. |

| 2. CAE algorithm predicts forming defects (accuracy > 95%) |

| 3. Reduce the secondary assembly process, and improve the yield rate to 98.6% |

| 4. Adopt nano-level CNC processing + EDM micro-hole technology |

| 5. Tight quality checks guarantee consistent, defect-free mold output |

| 6. Self-lubricating micro-hole structure design (oil-free stamping process). |

GreeDaikinMold holds multiple certifications, including ISO certification and AEO Advanced Customs Certification. The AEO Advanced Customs Certification has brought significant convenience to our company's import and export operations. Holding this certification enables us to enjoy various preferential policies in customs trade, such as lower inspection rates and priority in customs clearance procedures. These advantages can effectively shorten the customs clearance time of goods and ensure on-time fulfillment of customer delivery deadlines.

ZHUHAI GREE DAIKIN PRECISION MOLD CO., LTD.