| Availability: | |

|---|---|

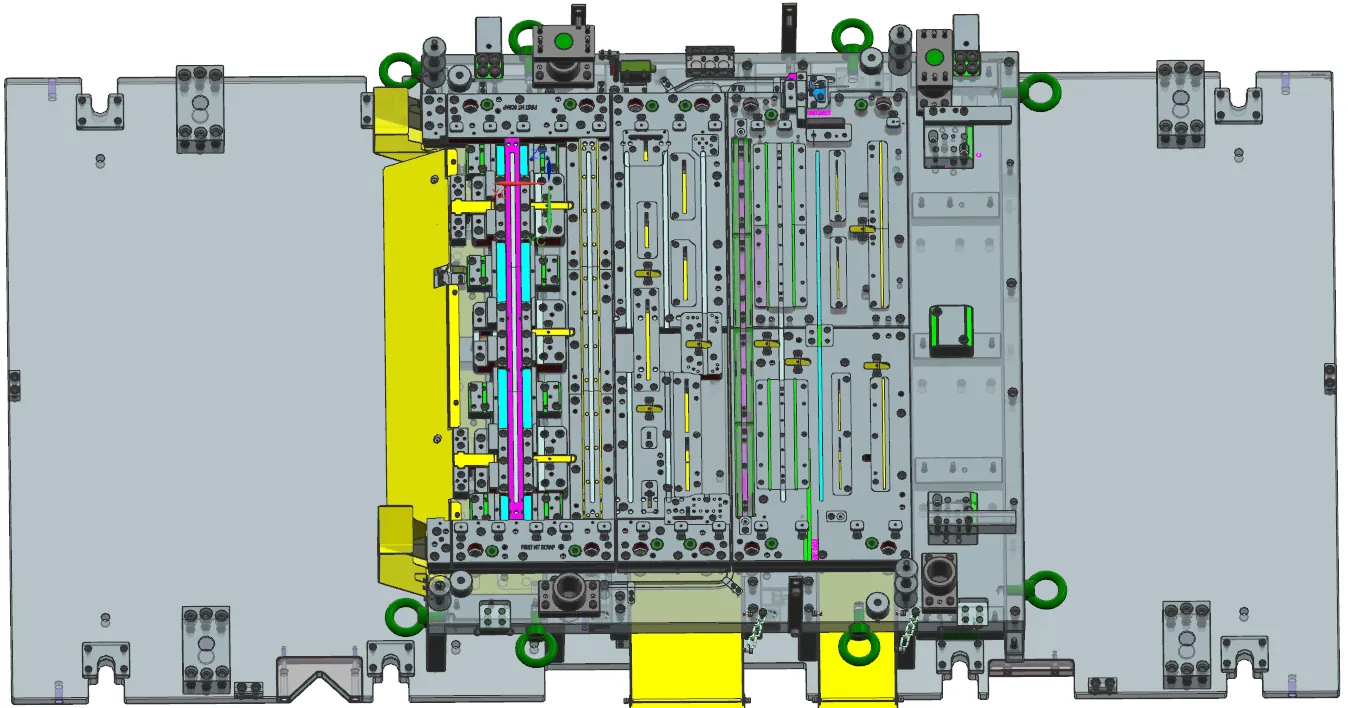

Air conditioner motor brackets stamping mold

| Tool structure design: Adopts full 3D modularization and precision standard library design |

| Tool production efficiency: Stamping die parts adopt a quick-change disassembly structure to facilitate cleaning and maintenance of internal components |

| Tool accessories: Adopt integrated standard processing, parts can be used in multiple dies to ensure the service life of the stamping mold |

| Stamping die production is an automatic line, a 4X400T punching machine robot production |

| Intelligent sensing mold system |

| CAE algorithm predicts molding defects (accuracy > 95%) |

| Reduce secondary assembly processes and increase the yield rate to 98.6% |

| Adopt nano-level CNC processing + EDM micro-hole technology |

| Certified On-Time Delivery Compliance |

| Self-lubricating micro-hole structure design (oil-free stamping process) |

Our business covers three major segments: injection mold, Stamping die, and precision part processing. Equipped with a complete set of technologies and equipment for mold solutions, we provide one-stop services to global customers. With extensive application fields, our products are mainly used in home appliances, auto parts, consumer electronics, medical devices, daily necessities, aviation parts, and other fields. The products are exported to over 20 countries and regions, including the United States, Mexico, Poland, India, and Malaysia. We have supporting mold after-sales service manufacturers in multiple countries and regions, ready to meet customers' needs for mold modification and repair.

Air conditioner motor brackets stamping mold

| Tool structure design: Adopts full 3D modularization and precision standard library design |

| Tool production efficiency: Stamping die parts adopt a quick-change disassembly structure to facilitate cleaning and maintenance of internal components |

| Tool accessories: Adopt integrated standard processing, parts can be used in multiple dies to ensure the service life of the stamping mold |

| Stamping die production is an automatic line, a 4X400T punching machine robot production |

| Intelligent sensing mold system |

| CAE algorithm predicts molding defects (accuracy > 95%) |

| Reduce secondary assembly processes and increase the yield rate to 98.6% |

| Adopt nano-level CNC processing + EDM micro-hole technology |

| Certified On-Time Delivery Compliance |

| Self-lubricating micro-hole structure design (oil-free stamping process) |

Our business covers three major segments: injection mold, Stamping die, and precision part processing. Equipped with a complete set of technologies and equipment for mold solutions, we provide one-stop services to global customers. With extensive application fields, our products are mainly used in home appliances, auto parts, consumer electronics, medical devices, daily necessities, aviation parts, and other fields. The products are exported to over 20 countries and regions, including the United States, Mexico, Poland, India, and Malaysia. We have supporting mold after-sales service manufacturers in multiple countries and regions, ready to meet customers' needs for mold modification and repair.

ZHUHAI GREE DAIKIN PRECISION MOLD CO., LTD.