| Availability: | |

|---|---|

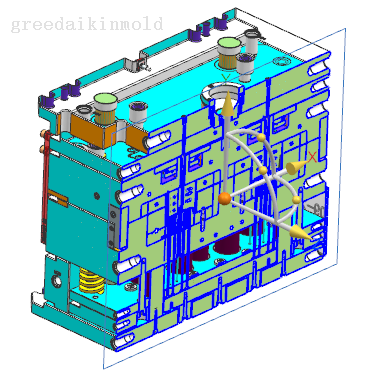

GreeDaikinMold specializes in precision mold manufacturing, serving two major companies(Gree & Daikin), and we also cater to a significant segment of other customers in the precision mold market. Adhering to customer requirements, GreeDaikinMold delivers molds that not only meet but often exceed client expectations. In practical applications, molds produced by GreeDaikinMold have demonstrated remarkable advantages over those from other manufacturers, both in product appearance and dimensional precision.

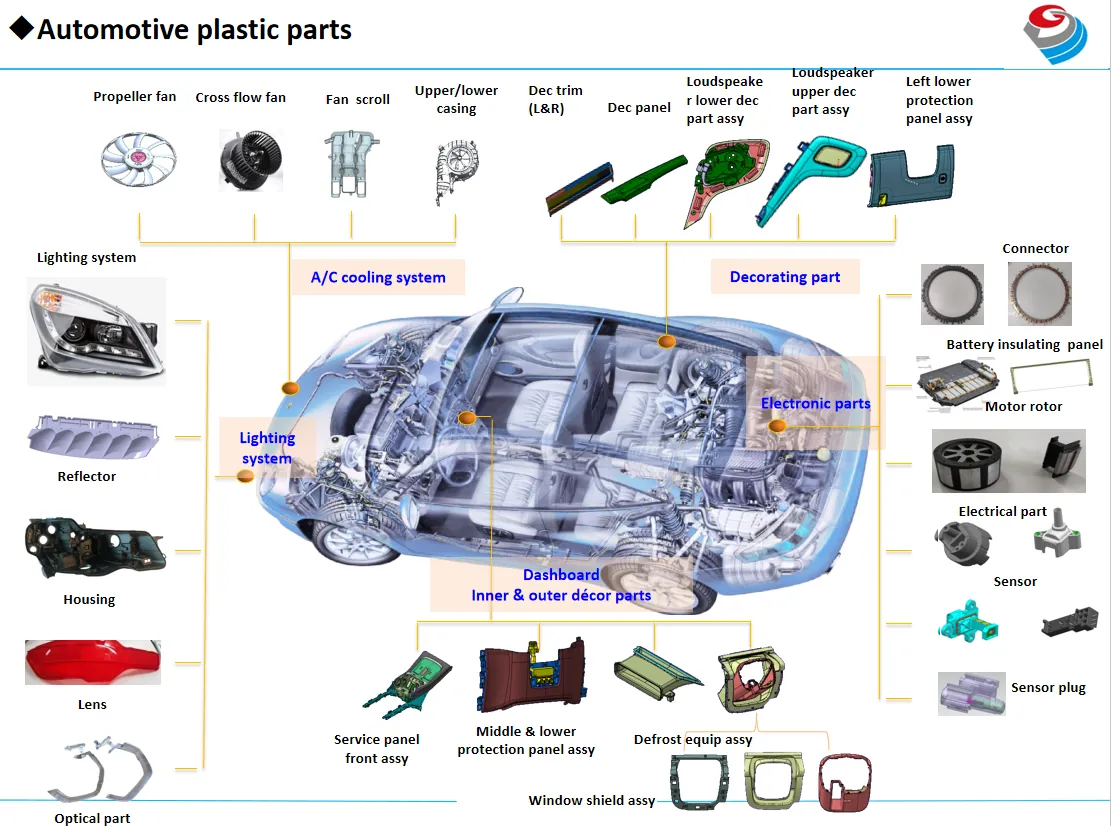

The cross-flow fan is a core component in modern automotive air conditioning systems, renowned for creating a quiet and comfortable airflow experience.

Unlike conventional fans that produce direct blowing, it operates on a unique transverse flow principle: air enters radially, passes through the fan wheel, and is discharged radially from the opposite side. This generates a broad, uniform, and gentle laminar airflow, mimicking a natural breeze and preventing discomfort.

In automotive HVAC units, it is tasked with steadily and evenly distributing conditioned air throughout the cabin. Its compact cylindrical shape is ideal for installation in confined spaces, such as under the dashboard, while ensuring low noise and high energy efficiency. It is a key element in enhancing driving and riding comfort.

The specifications are as follows:

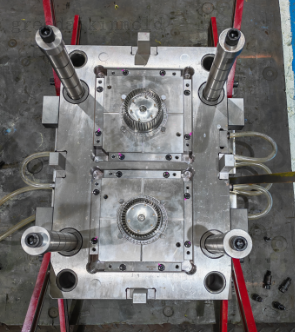

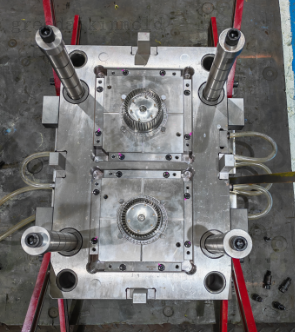

| Material | S50C,HPM38+Quenching |

| Standard Component | Misumi, PUNCH, etc. |

| Mold Base | Custom-made |

| Cavity Configuration | 1X2 |

| Injection Molding Machine Tonnage | 180T |

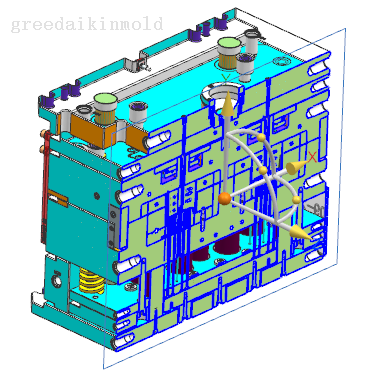

| We will adopt CAE analysis technology during the mold design period |

| To analyze the mixed deformation of the gate |

| Making suit plans for the pre-issues |

| Making an appropriate design for product requirements |

| Predicting deformation through CAE analysis |

| Designing the mold solution based on predictions |

| Achieving close alignment between trial molding and analysis |

| Delivering high-precision products within the scheduled timeframe |

GreeDaikinMold specializes in precision mold manufacturing, serving two major companies(Gree & Daikin), and we also cater to a significant segment of other customers in the precision mold market. Adhering to customer requirements, GreeDaikinMold delivers molds that not only meet but often exceed client expectations. In practical applications, molds produced by GreeDaikinMold have demonstrated remarkable advantages over those from other manufacturers, both in product appearance and dimensional precision.

The cross-flow fan is a core component in modern automotive air conditioning systems, renowned for creating a quiet and comfortable airflow experience.

Unlike conventional fans that produce direct blowing, it operates on a unique transverse flow principle: air enters radially, passes through the fan wheel, and is discharged radially from the opposite side. This generates a broad, uniform, and gentle laminar airflow, mimicking a natural breeze and preventing discomfort.

In automotive HVAC units, it is tasked with steadily and evenly distributing conditioned air throughout the cabin. Its compact cylindrical shape is ideal for installation in confined spaces, such as under the dashboard, while ensuring low noise and high energy efficiency. It is a key element in enhancing driving and riding comfort.

The specifications are as follows:

| Material | S50C,HPM38+Quenching |

| Standard Component | Misumi, PUNCH, etc. |

| Mold Base | Custom-made |

| Cavity Configuration | 1X2 |

| Injection Molding Machine Tonnage | 180T |

| We will adopt CAE analysis technology during the mold design period |

| To analyze the mixed deformation of the gate |

| Making suit plans for the pre-issues |

| Making an appropriate design for product requirements |

| Predicting deformation through CAE analysis |

| Designing the mold solution based on predictions |

| Achieving close alignment between trial molding and analysis |

| Delivering high-precision products within the scheduled timeframe |

content is empty!

ZHUHAI GREE DAIKIN PRECISION MOLD CO., LTD.