Views: 50 Author: Site Editor Publish Time: 2025-11-18 Origin: Site

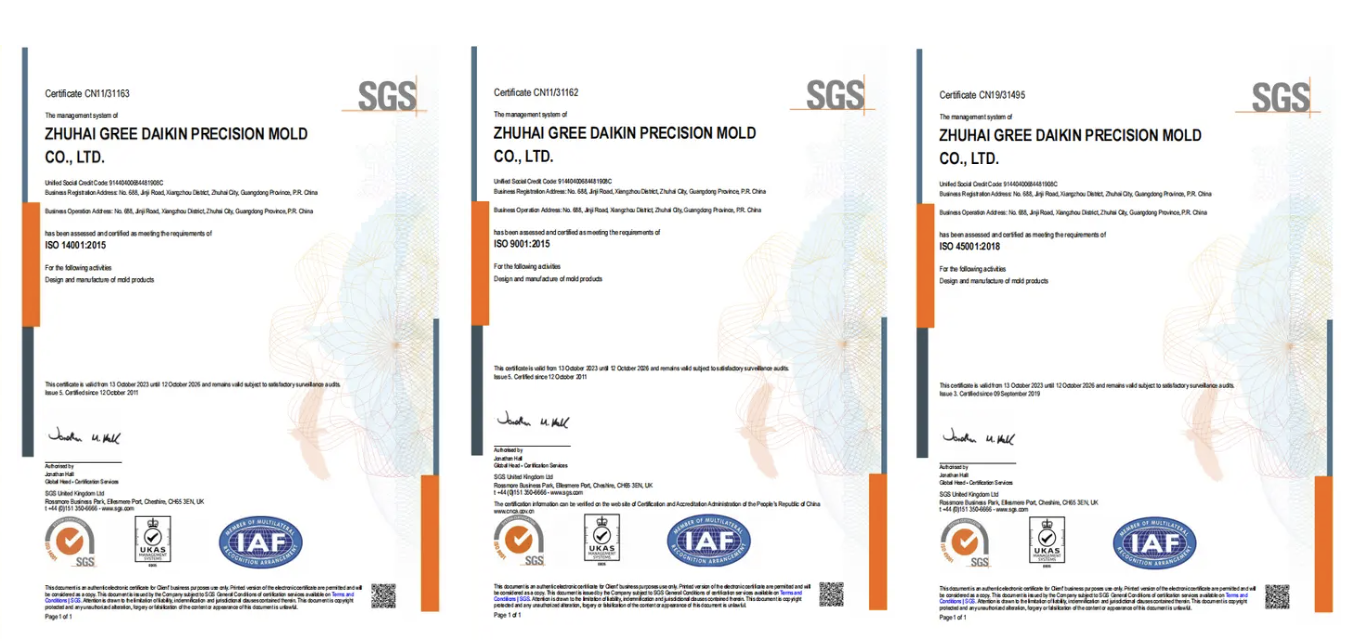

The Quality, Environment, and Occupational Health and Safety management system certifications are internationally recognized standards. From November 12 to 15, 2025, SGS conducted a surveillance audit for ZHUHAI GREE DAIKIN PRECISION MOLD CO., LTD. (hereinafter referred to as GDM) on its ISO 9001 Quality, ISO 14001 Environment, and ISO 45001 Occupational Health and Safety management systems. Following three days of rigorous on-site auditing by the SGS audit team, our company successfully passed the SGS surveillance audit once again.

This audit marks the 14th year since GDM first obtained the Quality Management System certification in 2011. The SGS audit team conducted a rigorous review of key departments, including the Sales Department and the Project Planning Section of the Production Management Department, through a sampling method. During the audit, GDM fully cooperated with the audit team's requests by providing access to documents, facilitating on-site inspections, and participating in personnel interviews. Furthermore, the company committed to further clarifying the management elements and applicable legal requirements related to quality, environment, and occupational health and safety in accordance with the "three systems" standards. It will continue to focus on customer needs, further optimize and standardize management procedures, and consistently enhance the effectiveness of the system operations. By maintaining a balance among economic, social, and environmental aspects, GDM aims to improve its management standards and promote sustainable development continuously.

The surveillance audit primarily covered areas such as risk and opportunity management, objectives and planning for their achievement, customer communication, product and service requirements, customer satisfaction, environmental aspects, and emergency preparedness and response. The following recommendations were provided for GDM's future work: The internal audit process could be further refined, including the completion of internal audit checklists; the Equipment and Power Department should enhance the management of energy conservation and emission reduction evaluations during the introduction of new equipment and ensure timely follow-up on equipment maintenance plans; the validation of training effectiveness should be improved; the stamping die Department should analyze non-conforming products by categorizing the causes of defects in mold part processing based on error frequency and factor them in by project completion milestones to minimize statistical fluctuations caused by order volume; it is recommended that the company streamline its documented information to enhance operational efficiency.

During the three-day audit meeting, the SGS audit team affirmed the effectiveness of our company's management system operations and, on behalf of SGS, presented the audit conclusion of "maintained certification" to GDM. Additionally, they provided valuable recommendations for the continuous improvement of our quality and environmental management systems. At the meeting, General Manager Dong Qing, representing the management, expressed gratitude to the SGS auditors for their dedicated efforts.

About GreeDaikinMold:

Zhuhai Gree Daikin Precision Mold Co., Ltd., a subsidiary of Gree Electric and Daikin Industries, was established in 2009. With 505 employees and a total area of 40,000 square meters, the company is a high-tech enterprise integrating mold R&D, design, production, and sales. It leverages 35 years of mold manufacturing experience from its parent companies.

Specializing in the development, production, and sales of precision molds (injection molds and stamping dies), the company achieves machining accuracy of up to 0.002 mm. We can provide an average of 1,200 mold sets annually. Its operational philosophy is centered on exceeding customer expectations to build a world-class mold enterprise and providing comprehensive mold solutions to clients.

GreeDaikinMold consistently emphasizes its management principles, which include three core aspects:

ISO 9001 - Quality Policy: Aim to exceed customer expectations and establish a world-leading mold enterprise.

ISO 14001 - Environmental Policy: Protect the living environment, implement energy conservation and emission reduction, and build a green factory.

ISO 45001 - Safety Policy: Ensure safe production, prevent risks, care for employees, and maintain a people-oriented approach.

Through continuous international standard system certification audits, the company consistently refines its operational management processes, strengthens its safety management system, and enhances risk control capabilities across all workflow stages.

GDM's leadership expressed full recognition of this surveillance audit, stating, "GDM will diligently implement international management system standards, strive to minimize operational risks, ensure the company's sound and healthy development, and continue to provide society with greener, more environmentally friendly, and healthier precision molds."

content is empty!

ZHUHAI GREE DAIKIN PRECISION MOLD CO., LTD.