| Availability: | |

|---|---|

We can customize various molds according to customer requirements, tailoring solutions for each client. Molds can be produced based on customer drawings or samples.

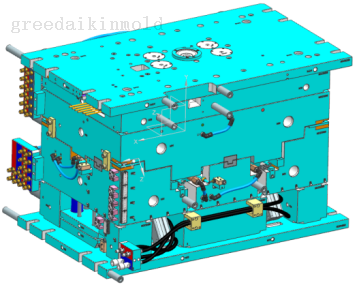

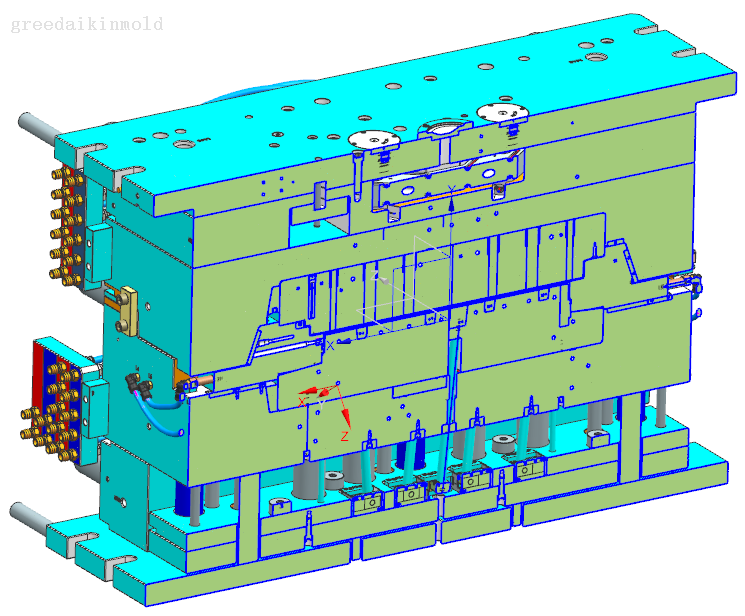

Hvac drain pan injection mold

The details of plastic mold as follows:

| Tool Material | S50C,718H,etc. |

| Standard parts | Self-made |

| Number of cavities | 1X1 |

| Injection molding machine tonnage | 1000T |

| Mold Life | 300,000 shots |

| 1.Our technical staff will analyze CAE results at the stage of early to avoid potentail issues,and optimise tool desgin Combaine with product requirments,we will continuously verify and optimize through CAE simulation analysis,Under the premise that the mold structure can be realized, determine the best gate position, optimize the product structure, and optimize product cooling by adding actual mold water to shorten the production cycle |

| 2.During product development, GreeDaikinMold has a professional product feasibility team that conducts feasibility analysis on various product issues and structures to avoid problems in advance |

| Greedaikinmold has more than 30 years of experience in customizing air conditioning injection molds |

| We have many global customer cases, covering high-end and mid-range air conditioner body mold product lines |

| Our company has more than 100 technical R&D personnel, and the mold customization technology is changing rapidly |

| 12-Hour On-Site Mold Support | Expert Engineers Available |

We can customize various molds according to customer requirements, tailoring solutions for each client. Molds can be produced based on customer drawings or samples.

Hvac drain pan injection mold

The details of plastic mold as follows:

| Tool Material | S50C,718H,etc. |

| Standard parts | Self-made |

| Number of cavities | 1X1 |

| Injection molding machine tonnage | 1000T |

| Mold Life | 300,000 shots |

| 1.Our technical staff will analyze CAE results at the stage of early to avoid potentail issues,and optimise tool desgin Combaine with product requirments,we will continuously verify and optimize through CAE simulation analysis,Under the premise that the mold structure can be realized, determine the best gate position, optimize the product structure, and optimize product cooling by adding actual mold water to shorten the production cycle |

| 2.During product development, GreeDaikinMold has a professional product feasibility team that conducts feasibility analysis on various product issues and structures to avoid problems in advance |

| Greedaikinmold has more than 30 years of experience in customizing air conditioning injection molds |

| We have many global customer cases, covering high-end and mid-range air conditioner body mold product lines |

| Our company has more than 100 technical R&D personnel, and the mold customization technology is changing rapidly |

| 12-Hour On-Site Mold Support | Expert Engineers Available |

content is empty!

ZHUHAI GREE DAIKIN PRECISION MOLD CO., LTD.