| Availability: | |

|---|---|

The airflow guide ring, though a single component within an air conditioning system, serves as a pivotal element that dictates the unit's overall performance, energy efficiency, and user experience. It acts as the strategic director of the airway, with its core value lying in the precise guidance and optimization of airflow to maximize systemic operational efficiency.

Firstly, the guide ring is fundamental to the unit's core performance and energy consumption. A well-engineered guide ring significantly reduces airflow resistance, ensuring air is delivered smoothly and evenly. This minimizes turbulence and energy loss, resulting in a significant improvement in heat exchange efficiency. Consequently, the compressor requires less power to achieve the same cooling or heating effect, resulting in substantial energy savings and a direct reduction in operational noise, leading to a quieter environment.

Secondly, it is central to ensuring user comfort. The bell mouth directly influences the angle, speed, and distance of airflow. An optimized design prevents cold air from blowing directly on occupants, effectively reducing the discomfort associated with "air conditioning sickness" and enabling uniform temperature distribution throughout the space. It elevates basic temperature control into a refined and comfortable experience.

Furthermore, its design and manufacturing quality are crucial for long-term reliability. In the injection molding of deep-cavity guide rings, improper control over shrinkage can lead to warping and dimensional inaccuracies. This not only compromises aerodynamic performance but can also cause stress cracks, shortening the product's lifespan. Therefore, precise management of shrinkage is the foundational guarantee for the product's enduring stability and performance.

In summary, the airflow guide ring is the critical link integrating the four core user demands: efficiency, comfort, quiet operation, and reliability. Though hidden from view, it is an indispensable cornerstone for achieving superior AC performance and quality. Every advancement in its technology pushes the entire industry toward more intelligent, energy-efficient, and user-centric solutions.

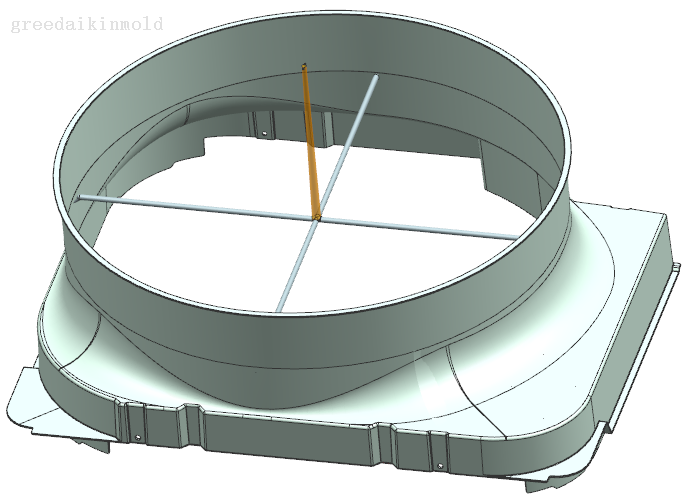

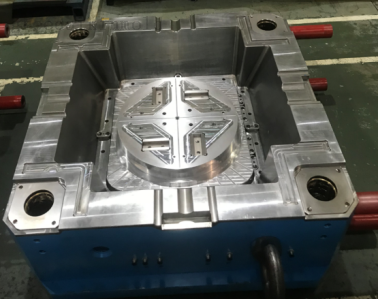

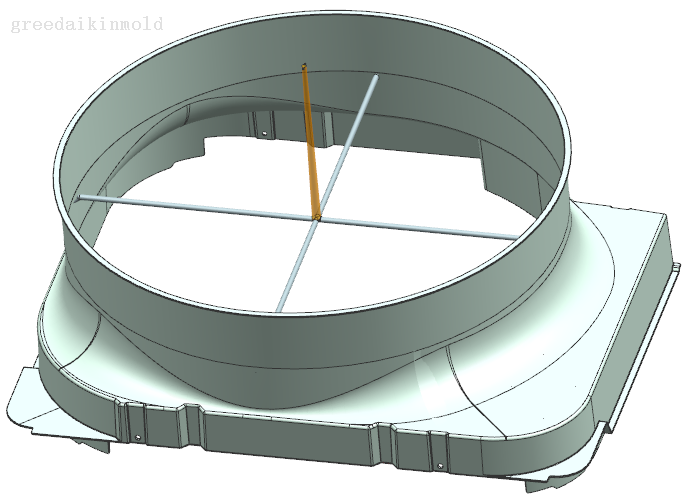

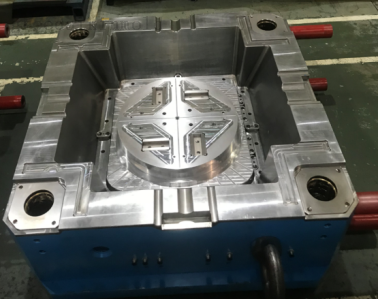

| The mold features a large overall size, with deep cavities that require high tonnage for the injection molding process. |

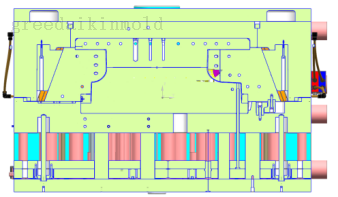

| For the airflow guide ring, the selection of gate location and size is critical. A large runner system is employed. CAE analysis determines the optimal gate dimensions to prevent defects such as weld lines, sink marks, and short shots, while also ensuring a balanced melt fill. |

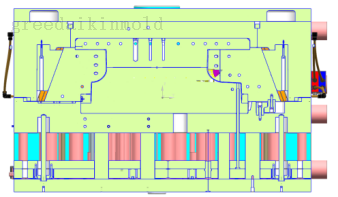

| Through upfront CAE simulation of the cooling circuit, the mold's water line layout is optimized. This ensures uniform mold temperature distribution, enhancing the final product's dimensional stability. |

| We are committed to meeting your needs by leveraging expert control over deep-cavity mold shrinkage to deliver aesthetically pleasing and reliable airflow guide rings, all underpinned by our proprietary GDM design standards and a team of industry specialists. |

| We Guarantee Your Timeline: Our holiday-proof production system operates year-round, ensuring your project never faces delays due to Chinese holidays, securing your time-to-market. |

| We Protect Your Investment: Our rigorous pre-shipment verification, from precision inspection to full testing, is designed to deliver mold-ready, high-performance tools that maximize your ROI. |

| We Protect Your Investment: Our rigorous pre-shipment verification, from precision inspection to full testing, is designed to deliver mold-ready, high-performance tools that maximize your ROI. |

The airflow guide ring, though a single component within an air conditioning system, serves as a pivotal element that dictates the unit's overall performance, energy efficiency, and user experience. It acts as the strategic director of the airway, with its core value lying in the precise guidance and optimization of airflow to maximize systemic operational efficiency.

Firstly, the guide ring is fundamental to the unit's core performance and energy consumption. A well-engineered guide ring significantly reduces airflow resistance, ensuring air is delivered smoothly and evenly. This minimizes turbulence and energy loss, resulting in a significant improvement in heat exchange efficiency. Consequently, the compressor requires less power to achieve the same cooling or heating effect, resulting in substantial energy savings and a direct reduction in operational noise, leading to a quieter environment.

Secondly, it is central to ensuring user comfort. The bell mouth directly influences the angle, speed, and distance of airflow. An optimized design prevents cold air from blowing directly on occupants, effectively reducing the discomfort associated with "air conditioning sickness" and enabling uniform temperature distribution throughout the space. It elevates basic temperature control into a refined and comfortable experience.

Furthermore, its design and manufacturing quality are crucial for long-term reliability. In the injection molding of deep-cavity guide rings, improper control over shrinkage can lead to warping and dimensional inaccuracies. This not only compromises aerodynamic performance but can also cause stress cracks, shortening the product's lifespan. Therefore, precise management of shrinkage is the foundational guarantee for the product's enduring stability and performance.

In summary, the airflow guide ring is the critical link integrating the four core user demands: efficiency, comfort, quiet operation, and reliability. Though hidden from view, it is an indispensable cornerstone for achieving superior AC performance and quality. Every advancement in its technology pushes the entire industry toward more intelligent, energy-efficient, and user-centric solutions.

| The mold features a large overall size, with deep cavities that require high tonnage for the injection molding process. |

| For the airflow guide ring, the selection of gate location and size is critical. A large runner system is employed. CAE analysis determines the optimal gate dimensions to prevent defects such as weld lines, sink marks, and short shots, while also ensuring a balanced melt fill. |

| Through upfront CAE simulation of the cooling circuit, the mold's water line layout is optimized. This ensures uniform mold temperature distribution, enhancing the final product's dimensional stability. |

| We are committed to meeting your needs by leveraging expert control over deep-cavity mold shrinkage to deliver aesthetically pleasing and reliable airflow guide rings, all underpinned by our proprietary GDM design standards and a team of industry specialists. |

| We Guarantee Your Timeline: Our holiday-proof production system operates year-round, ensuring your project never faces delays due to Chinese holidays, securing your time-to-market. |

| We Protect Your Investment: Our rigorous pre-shipment verification, from precision inspection to full testing, is designed to deliver mold-ready, high-performance tools that maximize your ROI. |

| We Protect Your Investment: Our rigorous pre-shipment verification, from precision inspection to full testing, is designed to deliver mold-ready, high-performance tools that maximize your ROI. |

ZHUHAI GREE DAIKIN PRECISION MOLD CO., LTD.