Views: 0 Author: Site Editor Publish Time: 2025-07-23 Origin: Site

The mold manufacturing industry is at a pivotal moment. Global competition, rising labor costs, and the demand for high-precision, low-cost, and fast-delivery molds have driven manufacturers to adopt Industry 4.0 technologies to transform traditional mold factories into smart mold factories. At the forefront of this transformation is ZHUHAI GREE DAIKIN PRECISION MOLD CO., LTD., a leading player specializing in mold manufacturing, focusing on high-precision injection molds and stamping dies for the automotive, home appliance and consumer electronics industries.

As the industry evolves, technologies like Automation, IoT, Digital Twin, AI-driven predictive maintenance, and cloud-based production management have begun to reshape mold manufacturing from manual, experience-dependent processes to intelligent, data-driven workflows. This article explores how smart mold factory concepts are applied in mold manufacturing, with practical cases and clear links to the precision mold products and capabilities offered by GREE DAIKIN, aligning with current market needs and the sustainability trend in global supply chains.

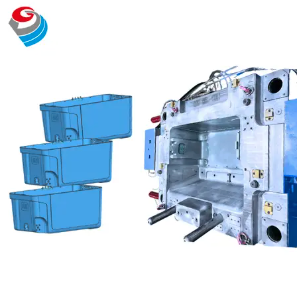

Mold manufacturing is a critical process for producing parts in various industries, requiring high precision, long tool life, and tight delivery timelines to support mass production. However, conventional mold factories face several challenges, including labor-intensive processes, inconsistent quality due to human error, lengthy lead times, high operational costs, and difficulties in managing complex mold designs. GREE DAIKIN PRECISION MOLD CO., LTD. addresses these challenges by adopting advanced manufacturing processes, precision machining, and rigorous quality control while actively exploring smart factory technologies to enhance productivity, quality, and efficiency.

A Smart Mold Factory integrates Industry 4.0 technologies to digitize, automate, and optimize the mold production lifecycle. This includes:

Digital Twin for mold design and simulation, allowing virtual prototyping and optimization before physical production. Digital twins can simulate multi-zone temperature control for complex molds and optimize valve gate sequencing for uniform filling. They also enable real-time monitoring of cycle times and thermal performance, ensuring design and manufacturing processes align with customer specifications.

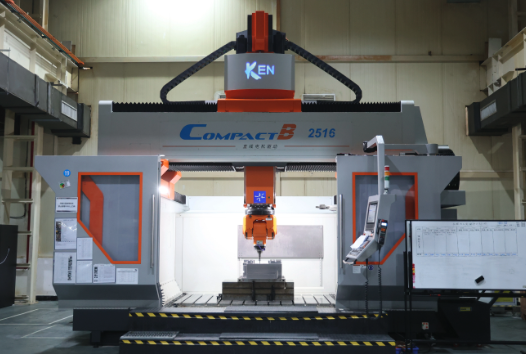

IoT sensors for real-time monitoring of equipment and processes, collecting data on parameters like spindle temperature, vibration analysis, and cooling channel flow rates and pressures. This enables predictive maintenance, identifying issues such as blockages in exhaust slots or waterway scaling before they impact production. At Gree Daikin Mold, implementing IoT systems enhances the reliability of high-precision molds used in air conditioner and automotive applications.

Automation and robotics for unattended machining and polishing, including automated polishing robots for mirror-finish mold cavities, AGVs for mold transport, and robotic arms for electrode loading/unloading in EDM machines. These technologies reduce manual labor dependency, ensuring consistent machining quality and shortened lead times.

Predictive maintenance using AI algorithms to analyze data from IoT sensors, predicting equipment failures and scheduling maintenance before serious damage occurs. This minimizes unexpected downtime, extends machine lifespan, and reduces repair costs.

Cloud MES systems for scheduling and traceability, improving production planning and ensuring transparency throughout the manufacturing process.

Energy monitoring and optimization to reduce operational costs and environmental impact.

Data-driven quality inspection using AI-powered systems to inspect molds for defects in real-time, reducing human error and improving precision.

Automation is fundamental to improving efficiency and reducing labor dependency. Automated solutions include:

Robotic arm loading/unloading of CNC machines, which enhances precision and consistency in mold production.

Automated polishing and EDM operations, ensuring high-quality surface finishes and reducing manual labor.

AGVs (Automated Guided Vehicles) for in-factory material transport, optimizing workflow and reducing downtime.

At GREE DAIKIN, automation helps in stabilizing production quality and increasing machining efficiency, particularly for large and precision molds where repetitive manual tasks can be replaced by robots.

IoT enables mold factories to collect real-time data on:

Spindle loads, helping to monitor and maintain optimal operating conditions.

Machine vibrations, enabling early detection of potential mechanical issues.

Coolant temperature and environmental humidity, ensuring consistent mold quality.

This data enables predictive insights for process stability and maintenance, ensuring consistent quality and reduced downtime in mold manufacturing.

A Digital Twin creates a virtual replica of a physical mold, allowing engineers to:

Simulate mold cooling and warpage, optimizing the design before physical production.

Optimize injection parameters, ensuring uniform filling and reducing defects.

Predict part quality before physical trials, reducing the number of mold trials and development costs.

Using digital twins reduces the number of mold trials, shortens lead times, and cuts development costs while improving first-shot success rates.

Predictive maintenance uses historical machine data and AI to predict failures before they occur. In mold factories, this ensures that high-value machining centers and EDM machines operate at maximum uptime while reducing unexpected repair costs.

Cloud-based Manufacturing Execution Systems (MES) enable real-time tracking of:

Production schedules, ensuring timely delivery of molds.

Equipment status, facilitating proactive maintenance.

Material traceability, enhancing quality control.

Quality inspection data, ensuring consistent product quality.

By integrating these Industry 4.0 technologies, mold manufacturers can achieve greater precision, reduce costs, improve quality, and increase overall efficiency in their operations.

To understand the practicality of these technologies, let’s explore examples from global mold manufacturers:

Makino (Japan) uses IoT-connected machining centers to optimize spindle utilization and detect anomalies. This approach allows for real-time monitoring of machine performance, enabling predictive maintenance and reducing downtime.

GF Machining Solutions (Switzerland) implements digital twin technology for EDM process simulation. By creating virtual replicas of molds and simulating the EDM process, GF can optimize parameters and reduce trial-and-error.

Husky Injection Molding Systems (Canada) integrates predictive maintenance to enhance mold uptime. Using AI algorithms to analyze sensor data, Husky can predict equipment failures and schedule maintenance proactively.

HASCO (Germany) uses RFID-enabled mold components for smart tracking and maintenance records. This allows for real-time monitoring of mold usage and condition, facilitating timely maintenance and reducing wear.

These practices align closely with GREE DAIKIN’s commitment to quality and innovation in precision mold manufacturing, offering reference frameworks for implementation.

| Aspect | Traditional Mold Factory | Smart Mold Factory (Industry 4.0) |

|---|---|---|

| Production Efficiency | Manual, labor-dependent | Automated with robotics, high throughput |

| Quality Stability | Operator skill-dependent | Data-driven consistency |

| Lead Time | Long, multi-iteration trials | Shortened via digital simulation and predictive scheduling |

| Maintenance | Reactive | Predictive with AI |

| Energy Consumption | High, uncontrolled | Monitored and optimized |

| Traceability | Limited | End-to-end digital traceability |

By shifting to a smart mold factory, manufacturers like GREE DAIKIN can respond to customer demands for shorter lead times, stable quality, and competitive pricing while improving internal operational efficiency.

AI-driven design tools will create optimized mold structures that reduce weight, material use, and cycle times. These tools leverage machine learning algorithms to generate designs that meet specific performance criteria while minimizing material usage and maximizing structural integrity. This not only reduces production costs but also enhances the efficiency and sustainability of mold manufacturing processes.

Metal 3D printing of conformal cooling inserts can further improve cooling efficiency in injection molds. Additive manufacturing allows for the creation of complex geometries that are difficult or impossible to achieve with traditional manufacturing methods. This technology enables the production of cooling channels that follow the contours of the mold, ensuring more uniform cooling and reducing cycle times.

Real-time analytics at the machine level will enhance immediate decision-making for quality and process adjustments. Edge computing allows for data processing and analysis directly at the source, enabling faster and more accurate decision-making. This technology can quickly identify and address issues in real-time, improving overall production efficiency and quality.

Technicians can use Augmented Reality to visualize maintenance steps, reducing downtime and errors. AR technology overlays digital information onto the physical environment, providing technicians with step-by-step instructions and visual guidance. This reduces the time required for maintenance tasks and minimizes the risk of errors, leading to improved uptime and reliability.

Smart mold factories will contribute data for carbon footprint reporting and ESG compliance for global clients. As environmental, social, and governance (ESG) criteria become increasingly important for businesses, smart mold factories will play a crucial role in providing accurate and transparent data. This will help companies meet their sustainability goals and demonstrate their commitment to responsible manufacturing practices.

A: A Smart Mold Factory integrates Industry 4.0 technologies to digitize, automate, and optimize the mold production lifecycle. This includes digital twins for design and simulation, IoT sensors for real-time monitoring, automation and robotics for unattended machining, predictive maintenance using AI, cloud-based MES systems for scheduling and traceability, energy monitoring, and data-driven quality inspection.

A: The mold manufacturing industry is adopting Industry 4.0 technologies to address challenges such as labor-intensive processes, inconsistent quality, lengthy lead times, high operational costs, and difficulties in managing complex mold designs. These technologies enhance productivity, quality, and efficiency, enabling manufacturers to meet the demands for high-precision, low-cost, and fast-delivery molds.

A: The key benefits of a Smart Mold Factory include higher precision molds, faster delivery cycles, stable and consistent quality, lower energy consumption, and enhanced sustainability and traceability. These benefits help manufacturers stay competitive in the global market and meet customer demands for cost-efficient, high-quality, and sustainable production.

A: Automation in mold manufacturing includes robotic arm loading/unloading of CNC machines, automated polishing and EDM operations, and AGVs for in-factory material transport. These solutions enhance precision, reduce manual labor dependency, and increase machining efficiency, particularly for large and precision molds.

A: IoT sensors in a Smart Mold Factory collect real-time data on spindle loads, machine vibrations, coolant temperature, and environmental humidity. This data enables predictive maintenance, process stability, and consistent mold quality, reducing downtime and improving overall efficiency.

The transformation toward smart mold factories under Industry 4.0 is no longer optional for mold manufacturing companies aiming to stay competitive in the global market.ZHUHAI GREE DAIKIN PRECISION MOLD CO., LTD., with its strong technical foundation and commitment to innovation, is positioned to integrate automation, IoT, digital twins, and AI-driven predictive maintenance into its mold manufacturing operations. This integration will deliver higher precision molds, faster delivery cycles, stable and consistent quality, lower energy consumption, and enhanced sustainability and traceability. By leveraging these advanced technologies, GREE DAIKIN is poised to set new industry standards in precision mold manufacturing, ensuring that their products meet the highest levels of quality and efficiency while contributing to a more sustainable future.

By embracing smart factory technologies, GREE DAIKIN not only strengthens its position as a leading mold manufacturer in China but also supports its global customers in achieving cost-efficient, high-quality, and sustainable production goals.If your business requires precision mold manufacturing aligned with the latest industry standards, partnering with GREE DAIKIN ensures your supply chain is prepared for the future of smart manufacturing.

Elevating Mold Manufacturing Excellence:GDM Mold Pouring and Design Expertise

Innovative Solutions in Mold Manufacturing by Zhuhai Greedaikin Precision Mold Company (GDM)

The Key Role of Rapid Response And Customization in Mold Manufacturing

How Digital Inspection Technologies Improve Mold Manufacturing Accuracy?

ZHUHAI GREE DAIKIN PRECISION MOLD CO., LTD.