Views: 0 Author: Site Editor Publish Time: 2025-09-26 Origin: Site

The copper tubes in air conditioners' condensers and evaporators pass through tube sheets, which provide support. These sheets contain numerous holes arranged in orderly patterns. Even with the same external dimensions, products can vary significantly due to different hole spacing layouts, resulting in numerous product models. This diversity requires mold changes to produce different styles.

Disassembling and reassembling molds is inherently time-consuming and labor-intensive. Coupled with the numerous product features and the large number of mold components, this process is prone to assembly fatigue, leading to missing or incorrectly installed parts.

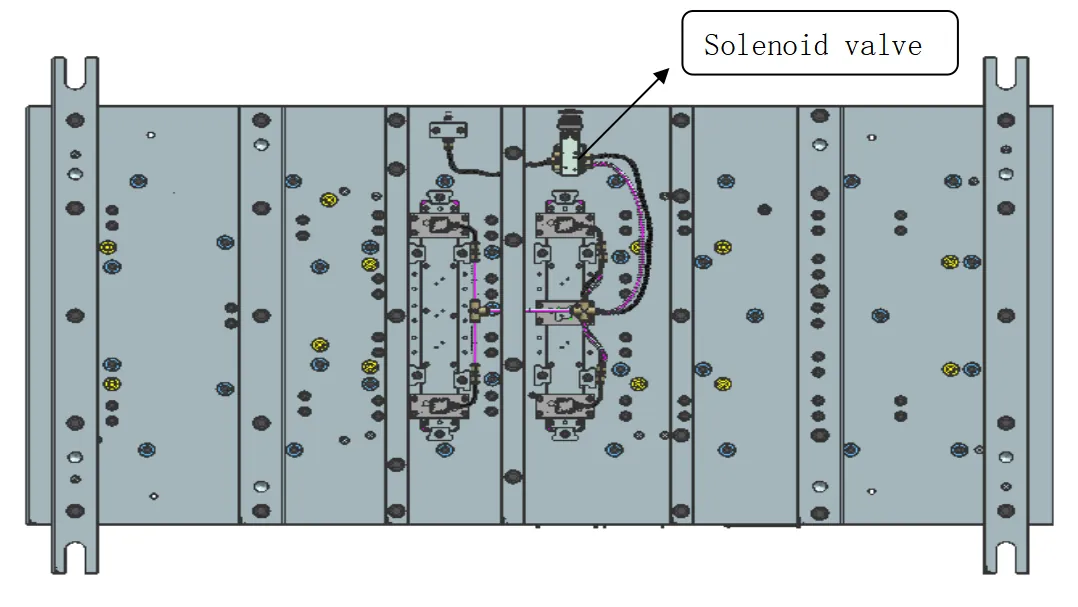

The sheet metal team boldly proposed an innovative idea. After multiple software simulations and automation studies, we introduced a pneumatic cylinder-based system for efficient model changeovers.

Some companies previously manufactured many similar products that were all manually assembled and disassembled, which was not only inefficient in terms of time and labor costs, but also led to errors and a poor customer experience. Our air cylinder promotes the workflow and pushes the operation to optimize the pattern-changing structure. No need to remove the mold; the pattern can be changed with one click on the machine. This ensures the stability of the customer's product and has been praised by customers.

Core Application and Value of Ejector Sleeves

Ejector sleeves are used to eject deep, narrow pillars or screw bosses, preventing ejection marks (whitening) or damage to the part, making them a critical design for precision ejection.

Stringent Design Specifications for Ejector Sleeves

Our design must adhere to strict standards for hardness (≥HRC 60), wall thickness (≥1mm), fit clearance (based on the plastic flash value), and custom length (rounded to the nearest 5 or 0 mm).

Innovative Structures to Address Pain Points

To address core-shut durability issues, flexible support (e.g., polyurethane) is used; to tackle the challenge of frequent mold changes for multiple product styles, an automated pneumatic cylinder-based changeover system was proposed to reduce human error and improve efficiency.

Layout and Assembly Coordination

Mold design requires a holistic approach to ensure the layout of ejector sleeves/pins does not interfere with other components, like ejector pins, lifters, or guide pillars. For densely populated areas, optimized designs such as shared clamp blocks can be utilized.

ZHUHAI GREE DAIKIN PRECISION MOLD CO., LTD.