Views: 0 Author: Site Editor Publish Time: 2025-09-05 Origin: Site

With the development of industrial manufacturing, the market is more and more focus the mold industry, and requires high technical process.

Application of CAE Technology

On the importance of 3D digital mold technology: it serves as the foundation for integrating stamping die design, manufacturing, and inspection. Industrial development relies heavily on the rapid advancement of computer software and hardware, among which the application of CAE technology significantly reduces trial mold costs.

3D CAE technology has become a powerful tool for predicting forming processes in advance. Therefore, the mold industry today also requires reform and innovation, with a focus on "efficiency, profitability, automation, and informatization."

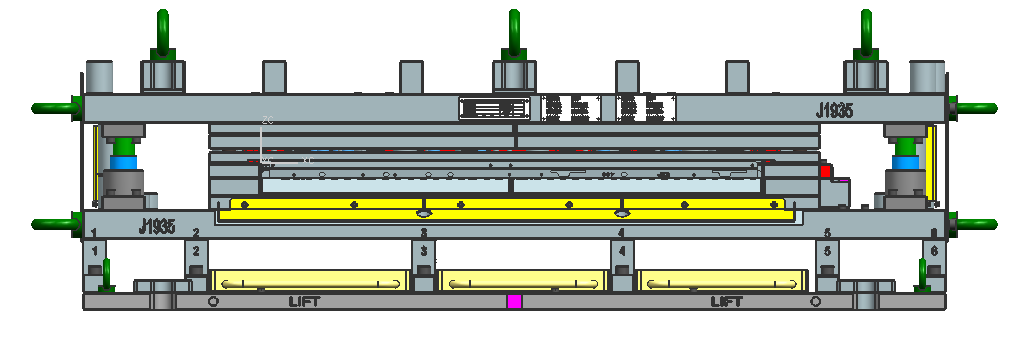

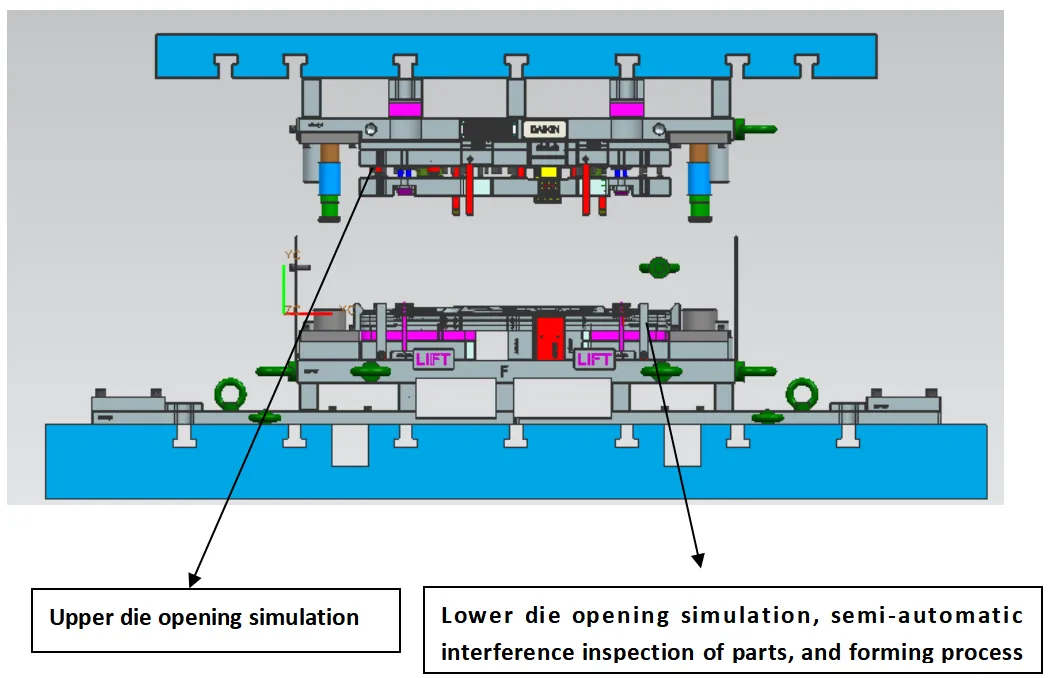

3D Design stamping die Display

GreeDaikinMoldStructure Design has consistently adhered to 3D mold design. From product input—mold evaluation—mold structure improvement—to engineering drawing output: 3D technology intuitively reflects the status of the mold, revealing otherwise invisible issues and reducing error rates caused by mold design, thereby cutting costs.

CAE forming analysis the springback, to carry out risk control in advance

GreeDaikinMold has extensive experience in stamping molds, automation, intelligent manufacturing, and CAE analysis.

The Advantages of 3D stamping die Desgin

During the mold design phase, CAE software such as Moldflow is comprehensively utilized to conduct mold flow analysis, cooling analysis, stress analysis, and more. This enables the early prediction and resolution of potential issues such as short shots, shrinkage, air traps, and warpage. It significantly shortens the mold trial cycle and reduces costs, achieving the design goal of "getting it right the first time.

We specialize in custom mold making for a wide range of industries, including household appliances, automotive components, and medical equipment. Our service includes collaborative mold design and the recommendation of the most cost-effective solutions based on your specific requirements and material selection.

ZHUHAI GREE DAIKIN PRECISION MOLD CO., LTD.