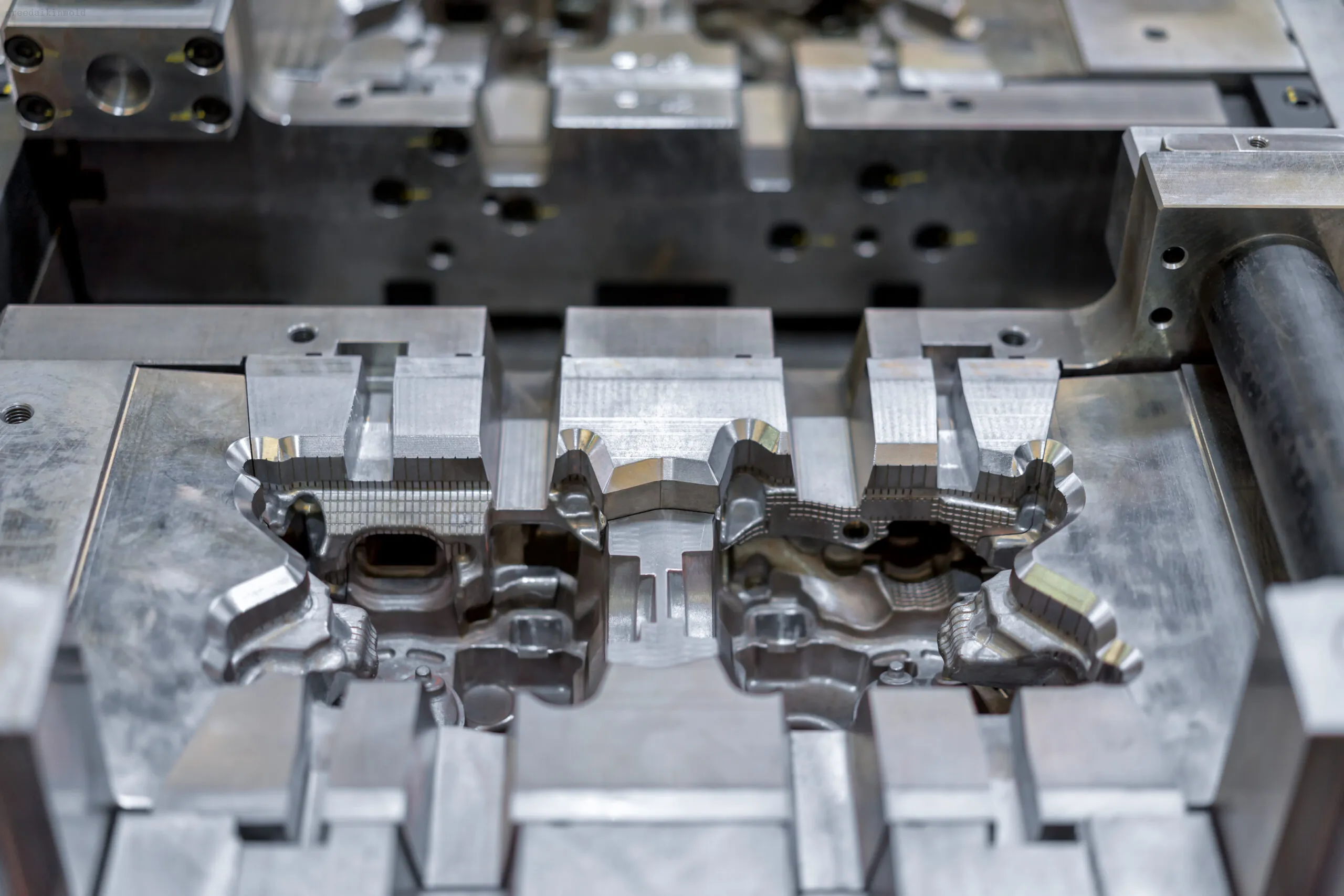

Automotive Core insert

Automotive die casting mold

DHD→ CNC1 → EDM2 → RD → Pol → DHD → Pol→ IPQC→ HT → RD→ Gri-M → CNC6-A66 → CNC4 → EDM1 → WEDM-20 → Pol → IPQC

| The casting mold can effectively resist hot tears in high temperature and high pressure working environmen |

| Professional technical support to extend the service life of molds |

| We use advanced processing equipment and precise measurement technology to ensure extremely small dimensional tolerances |

| The parts and accessories we process are precisely matched with the mold, thus improving the molding quality and dimensional accuracy of the die-casting product |

Automotive Core insert

Automotive die casting mold

DHD→ CNC1 → EDM2 → RD → Pol → DHD → Pol→ IPQC→ HT → RD→ Gri-M → CNC6-A66 → CNC4 → EDM1 → WEDM-20 → Pol → IPQC

| The casting mold can effectively resist hot tears in high temperature and high pressure working environmen |

| Professional technical support to extend the service life of molds |

| We use advanced processing equipment and precise measurement technology to ensure extremely small dimensional tolerances |

| The parts and accessories we process are precisely matched with the mold, thus improving the molding quality and dimensional accuracy of the die-casting product |

content is empty!

ZHUHAI GREE DAIKIN PRECISION MOLD CO., LTD.