| Availability: | |

|---|---|

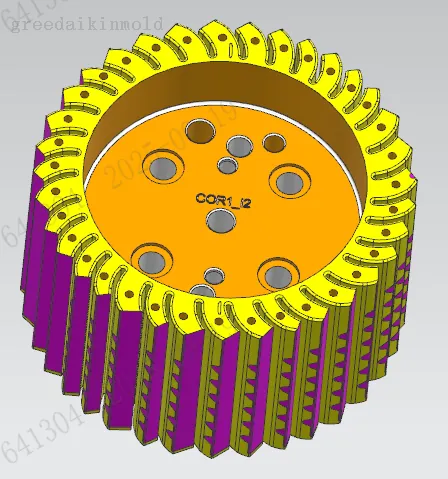

Moving Mold Insert

| Materia | S136 |

| Product Dimensions | 160.000X160.000X65.000 |

| Application industries | Home appliance |

| Processing | CNC1 →Per →HT →Gri-M →Gri-S →CNC3 →WEDM →EDM →POL →IPQC |

| We control the measurement reference within 0.003mm by machining parts using high-precision grinding machines. |

| The measurement datum of parts processed by a high-precision grinding machine. The position accuracy of processed parts shall be guaranteed within ±0.01mm, the parallelism shall be 0.005mm, and the profile tolerance shall be 0.1mm by measuring the center point of four points and a high-precision datum plane |

Our Advantages

GreeDaikinMold has mature processing technology and advanced processing machines. The Kuroda grinding machine ensures ultra-high precision and surface finish. The Mitsubishi wire cutting process uses specially developed high-precision fixtures for accurate swing angle positioning and fast clamping. Additionally, we have the internationally well-known Makino CNC machine, with mature and experienced technicians to operate it. By using precision inspection methods and tightly connecting all procedures, we can achieve efficient processing and reliable quality.

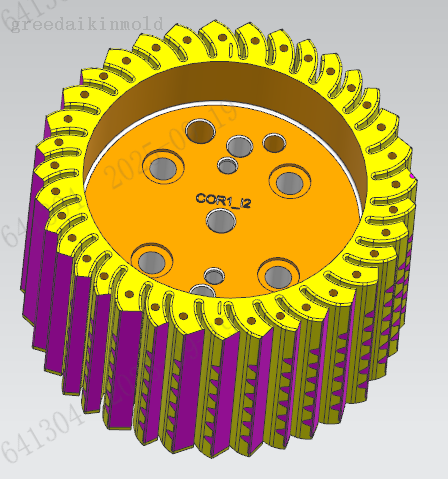

Moving Mold Insert

| Materia | S136 |

| Product Dimensions | 160.000X160.000X65.000 |

| Application industries | Home appliance |

| Processing | CNC1 →Per →HT →Gri-M →Gri-S →CNC3 →WEDM →EDM →POL →IPQC |

| We control the measurement reference within 0.003mm by machining parts using high-precision grinding machines. |

| The measurement datum of parts processed by a high-precision grinding machine. The position accuracy of processed parts shall be guaranteed within ±0.01mm, the parallelism shall be 0.005mm, and the profile tolerance shall be 0.1mm by measuring the center point of four points and a high-precision datum plane |

Our Advantages

GreeDaikinMold has mature processing technology and advanced processing machines. The Kuroda grinding machine ensures ultra-high precision and surface finish. The Mitsubishi wire cutting process uses specially developed high-precision fixtures for accurate swing angle positioning and fast clamping. Additionally, we have the internationally well-known Makino CNC machine, with mature and experienced technicians to operate it. By using precision inspection methods and tightly connecting all procedures, we can achieve efficient processing and reliable quality.

ZHUHAI GREE DAIKIN PRECISION MOLD CO., LTD.