| Availability: | |

|---|---|

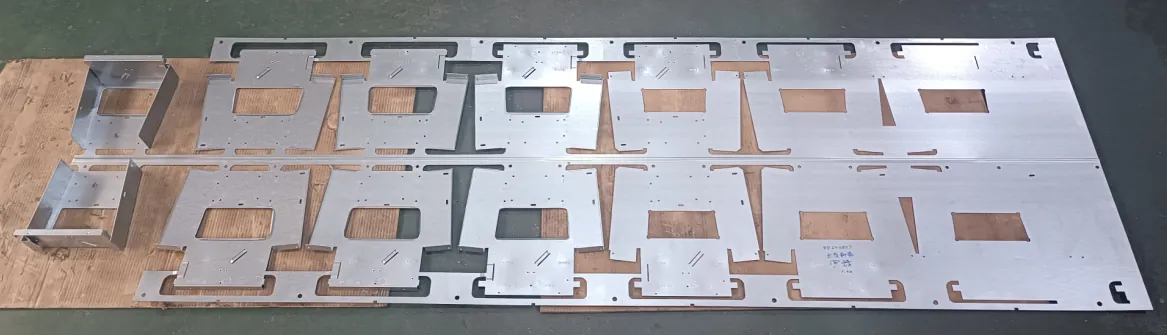

HVAC bracket die

The detailed information of the Stamping Die is as follows:

| Core and cavity steel | Stainless steel, Aluminum alloy, D2, DC53, Gr12mo1v1, etc. |

| Stanard parts | Punch, Misumi, etc. |

| Die set | Self-made |

| Stamping speed | 30SPM |

| Tool devitry time | 50-60days |

| Tool life | 300,000 shots |

| Tool structure design: Adopt a full 3D modular quick-change structure (15 minutes to complete mold reorganization) design |

| Tool Production efficiency: Tool parts adopt a standard quick-change disassembly structure, which is convenient for mold cost reduction, efficiency improvement, and maintenance |

| Tool accessories: Adopt integrated standard processing, parts can be used in multiple molds, ensuring the service life of the die |

| Tool production is continuous mold production + automatic line punching machine robot production |

| Fast die manufacturing cycle |

| Small and medium batch order switching efficiency increased by 80%, and scrap rate reduced to 0.8% |

| Nanocrystalline ceramic surface treatment (friction coefficient reduced by 65%) |

| Good after-sales service |

| Strict quality control |

| Multi-layer composite guide column system (verticality error <0.02/100mm) |

We will provide you with a satisfactory die solution. If you are looking for air conditioning molds, please come to us for an inquiry

HVAC bracket die

The detailed information of the Stamping Die is as follows:

| Core and cavity steel | Stainless steel, Aluminum alloy, D2, DC53, Gr12mo1v1, etc. |

| Stanard parts | Punch, Misumi, etc. |

| Die set | Self-made |

| Stamping speed | 30SPM |

| Tool devitry time | 50-60days |

| Tool life | 300,000 shots |

| Tool structure design: Adopt a full 3D modular quick-change structure (15 minutes to complete mold reorganization) design |

| Tool Production efficiency: Tool parts adopt a standard quick-change disassembly structure, which is convenient for mold cost reduction, efficiency improvement, and maintenance |

| Tool accessories: Adopt integrated standard processing, parts can be used in multiple molds, ensuring the service life of the die |

| Tool production is continuous mold production + automatic line punching machine robot production |

| Fast die manufacturing cycle |

| Small and medium batch order switching efficiency increased by 80%, and scrap rate reduced to 0.8% |

| Nanocrystalline ceramic surface treatment (friction coefficient reduced by 65%) |

| Good after-sales service |

| Strict quality control |

| Multi-layer composite guide column system (verticality error <0.02/100mm) |

We will provide you with a satisfactory die solution. If you are looking for air conditioning molds, please come to us for an inquiry

content is empty!

ZHUHAI GREE DAIKIN PRECISION MOLD CO., LTD.