Views: 0 Author: Site Editor Publish Time: 2025-09-17 Origin: Site

During the production adjustment process of injection molds, the mold temperature is often increased to facilitate adjustments and improve the product's appearance.

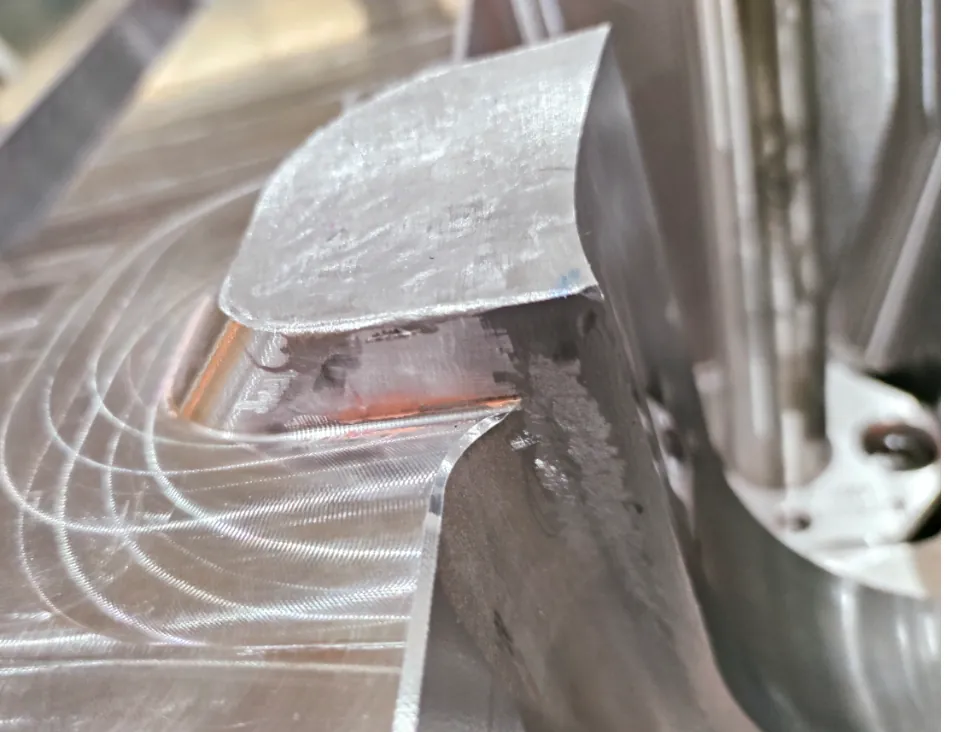

However, many molds are not matched to simulate production conditions during the mold matching process, resulting in the mold insertion position being prone to burning during production, as shown in the following figure:

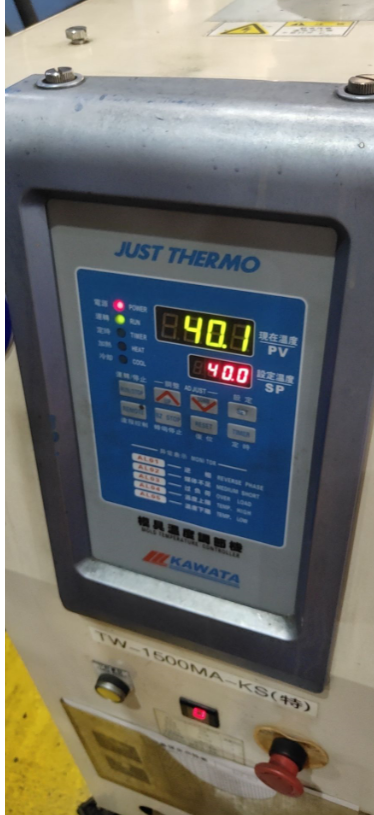

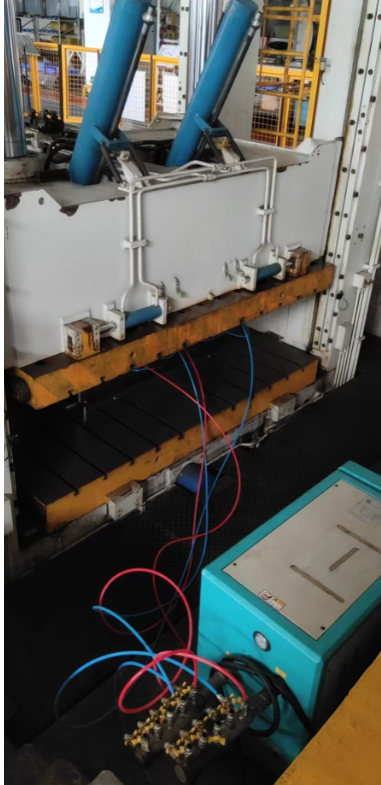

To prevent this burning phenomenon, the mold simulates the production state during mold matching, and the mold temperature is connected to the mold temperature controller to make the mold temperature reach the same temperature as the production state, and then the mold is matched, as shown in the following figure:

By simulating the production status and matching the mold, the production plug-in problem can be effectively solved.

ZHUHAI GREE DAIKIN PRECISION MOLD CO., LTD.