| Availability: | |

|---|---|

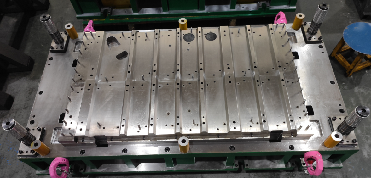

Air Conditioner bottom panel stamping die

The details of the air conditioner bottem panel stamping die as follows:

| Tool material | P20,45#,D2,DC53,Gr12mo1v1,ect. |

| Standard parts | PUNCH,MISUMI,ect. |

| Die Set | Self-made |

| Stool Hardness | SGCC,SGCD2,DX56D,ect. |

| Tool carvity | 1X1 |

| Deviery Time | 50-60 Days |

| Punch Speed | 30 SPM |

| Tool life | 300,000 Shots |

| 1.The desgin of stamping die structure We adopt the whole 3d modle and precision desgin |

| 2.Stamping production effeciency The parts adopt quciky stwich structure,it's convient for works to clean and maintain |

| 3.Stamping Accessiories We adopt standard manufacturing,the part can suit for many dies |

| 4.The tool production is automatic line 4X400T punching machine robot production |

| Sensoir system Intelligent sensing mold system |

| CAE algorithm predicts molding defects (accuracy > 95%) |

| Reduce secondary assembly process and increase the yield rate to 98.6% |

| Adopt nano-level CNC processing + EDM micro-hole technology |

| Strict quality control |

| Self-lubricating microporous structure design (oil-free stamping process) |

| Strict quality control |

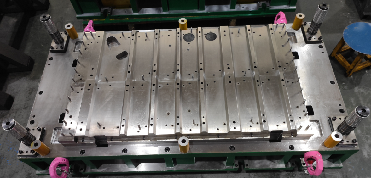

Air Conditioner bottom panel stamping die

The details of the air conditioner bottem panel stamping die as follows:

| Tool material | P20,45#,D2,DC53,Gr12mo1v1,ect. |

| Standard parts | PUNCH,MISUMI,ect. |

| Die Set | Self-made |

| Stool Hardness | SGCC,SGCD2,DX56D,ect. |

| Tool carvity | 1X1 |

| Deviery Time | 50-60 Days |

| Punch Speed | 30 SPM |

| Tool life | 300,000 Shots |

| 1.The desgin of stamping die structure We adopt the whole 3d modle and precision desgin |

| 2.Stamping production effeciency The parts adopt quciky stwich structure,it's convient for works to clean and maintain |

| 3.Stamping Accessiories We adopt standard manufacturing,the part can suit for many dies |

| 4.The tool production is automatic line 4X400T punching machine robot production |

| Sensoir system Intelligent sensing mold system |

| CAE algorithm predicts molding defects (accuracy > 95%) |

| Reduce secondary assembly process and increase the yield rate to 98.6% |

| Adopt nano-level CNC processing + EDM micro-hole technology |

| Strict quality control |

| Self-lubricating microporous structure design (oil-free stamping process) |

| Strict quality control |

content is empty!

ZHUHAI GREE DAIKIN PRECISION MOLD CO., LTD.