Views: 0 Author: Site Editor Publish Time: 2025-12-08 Origin: Site

To ensure the production of qualified plastic injection molds, a Precision mold manufacturer must focus on enhancing mold quality. What measures can be taken to improve the quality of plastic injection molds?

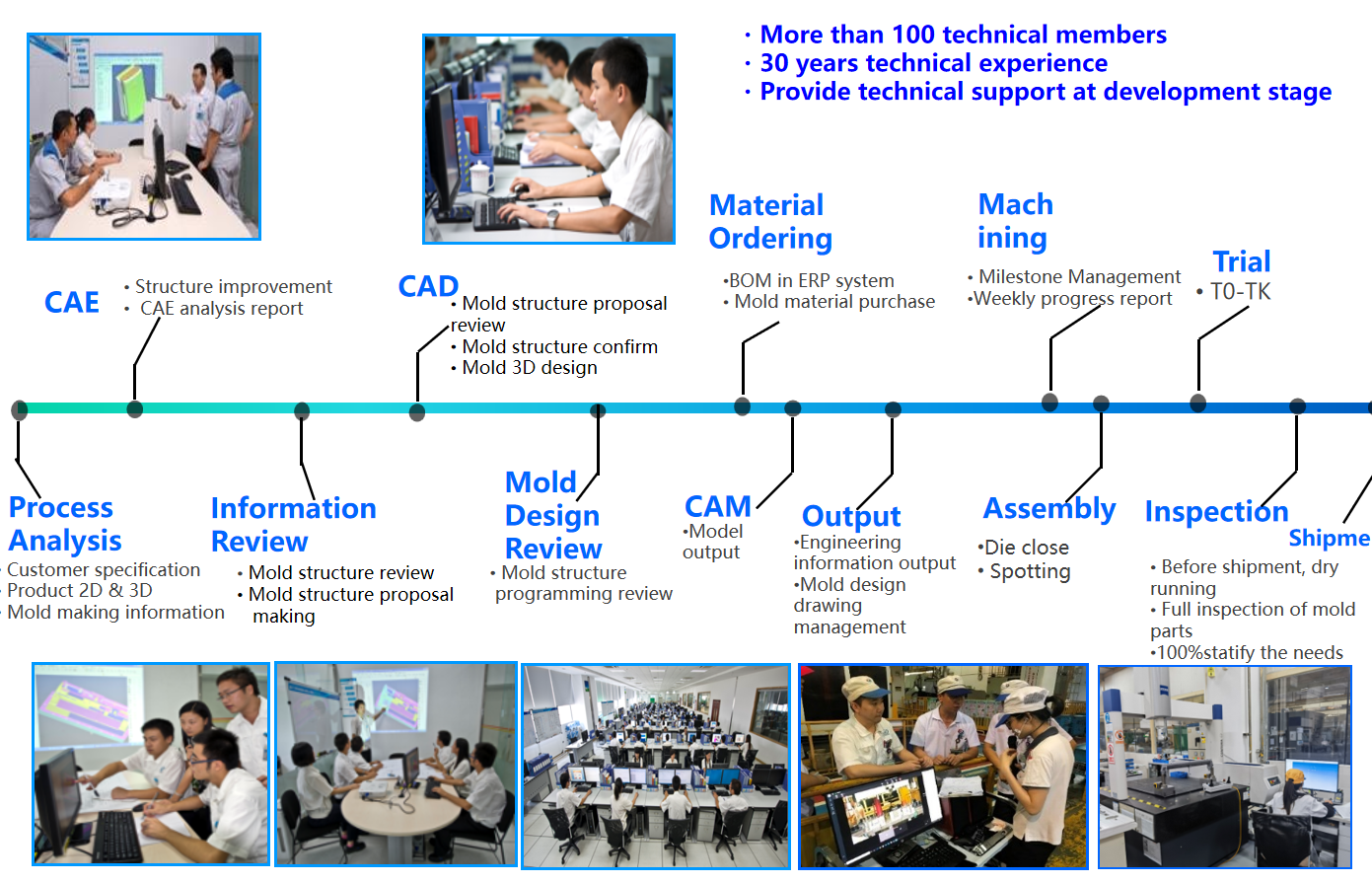

Mold manufacturers need to establish a comprehensive production management system for plastic molds to achieve full digital management of product data, process data, planning, and scheduling throughout the production workflow. This system should cover mold production planning, mold design, process design, workshop task assignment, product inspection, and warehouse management, enabling end-to-end tracking of plastic mold manufacturing and related auxiliary information from planning to final delivery.

1. Integrated Production Management System

Mold manufacturers must organically integrate and coordinate information from planning, design, process engineering, shop floor production, and human resources.

This synergy between planning and execution ensures both plastic mold quality and on-time delivery.

2. Cost & Quality Control

By strictly controlling work order issuance and managing tool scrappage, along with precise mold structure design, efficient part machining, and accurate component inspection, additional costs arising from design changes and repairs can be significantly reduced. This enables accurate calculation of actual cost per mold and effective control over mold quality.

3. Criticality of Mold Assembly

Mold assembly is akin to precision machinery assembly—every component and every screw must be correctly placed. Any error may lead to product defects and production delays in minor cases, or to severe mold damage and complete scrappage in worst cases. Hence, assembly must be executed with utmost meticulousness.

4. Cleaning Protocol During Assembly

Cleaning is particularly crucial during assembly, especially for water channels and screw holes. All metal chips must be thoroughly blown out to prevent serious customer dissatisfaction.

5. Mold Maintenance & Preservation

Mold maintenance primarily refers to upkeep during production intervals. Like automobiles, molds risk permanent damage if stored long-term without proper care. Therefore, comprehensive maintenance should be performed after each production run, emphasizing rust prevention on molding surfaces and lubrication of moving parts.

Since molds are exposed to cooling water during production and may get wet during installation or disassembly, they must be fully dried before applying a protective oil coating.

In a word, enhancing the quality of injection molds is a systematic endeavor that requires refined, full-process control spanning management coordination, process control, and post-production maintenance. A mold manufacturer must first integrate and coordinate information from planning, design, process engineering, production, and human resources to effectively align scheduling with execution, thereby ensuring both mold quality and delivery timelines. On the front of cost and quality control, strict management of workshop job orders and regulated tool scrappage—combined with precise mold structural design, efficient component machining, and accurate inspection—can significantly reduce additional costs arising from design changes and repairs, achieving dual optimization of quality and price. The mold assembly phase is critical; akin to precision machinery assembly, every component and screw must be error-free. Any oversight may lead to product defects in minor cases or complete mold scrappage in severe instances, necessitating extremely meticulous assembly work. Cleaning is particularly vital during this stage, especially for water channels and screw holes, where all metal chips must be thoroughly removed to prevent customer complaints. Mold maintenance is equally indispensable. Like an automobile, a mold left idle for extended periods without proper care can easily become irreparably damaged. Therefore, comprehensive maintenance should be performed after each production run, focusing on rust prevention in molding areas and lubrication of moving parts. After exposure to cooling water, the mold must be completely dried before applying a rust-preventive oil. Only through such end-to-end, interlinked systematic control can mold precision and longevity be guaranteed at the source, ultimately delivering high-quality, highly reliable injection mold products to customers.

ZHUHAI GREE DAIKIN PRECISION MOLD CO., LTD.