Views: 0 Author: Site Editor Publish Time: 2025-10-10 Origin: Site

1. Causes and Suppression Methods of Warping and Twisting in Stamped Parts Produced by Progressive Dies

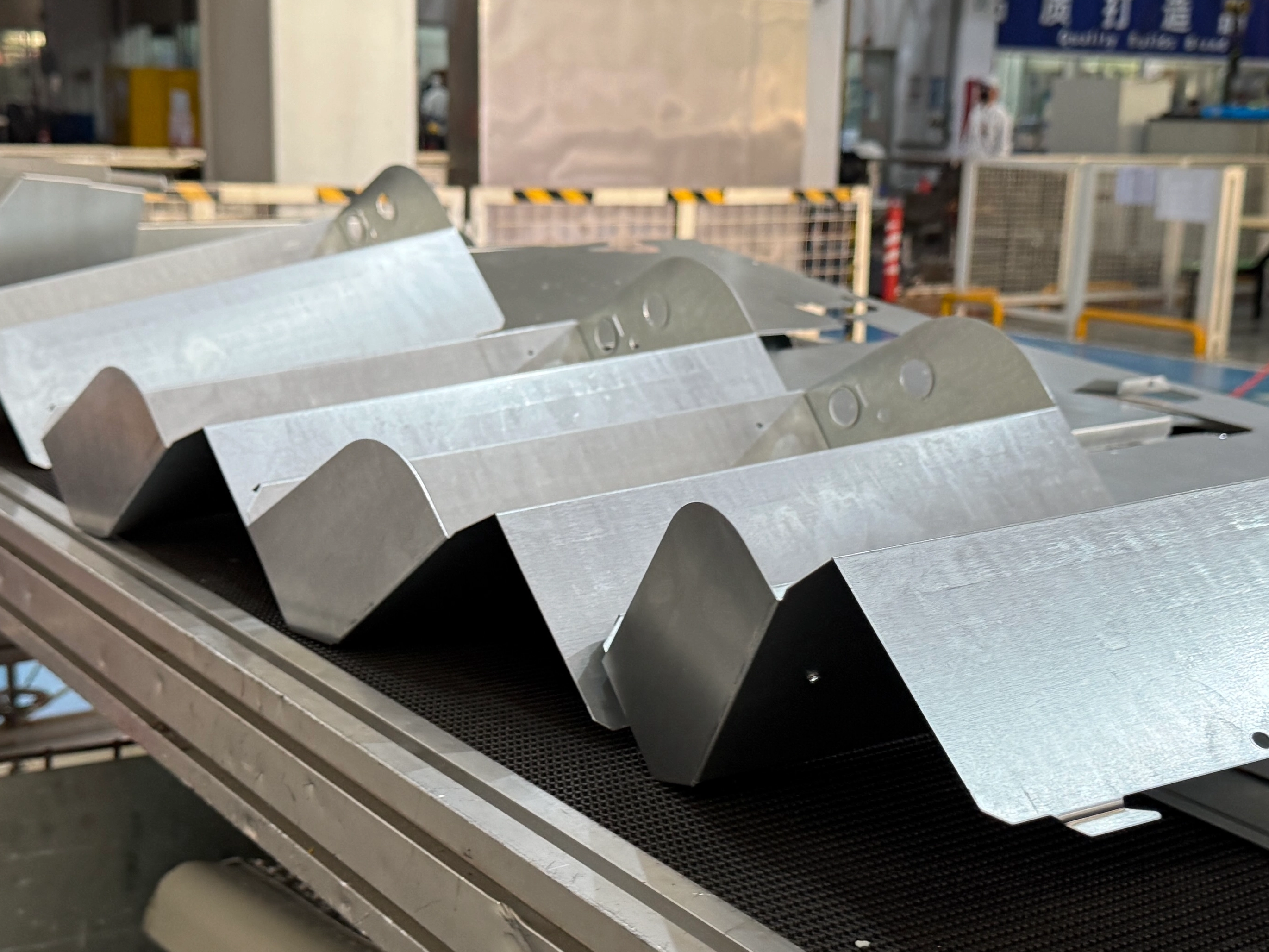

Stamping is a common workshop production method that enables the manufacture of metal workpieces with high complexity. During the stamping process, factors such as stamping depth, die material, and design can lead to occurrences of warping and twisting, which affect the quality of the stamped parts and may even increase the product rejection rate. Warping and twisting are relatively common issues in progressive dies. This article discusses the causes of warping and twisting in stamped parts and provides methods to mitigate them.

2. Reasons for flipping and twisting of stamped parts in progressive dies

Focusing on the various causes mentioned above, we will discuss several key issues concerning die repair analysis.

2-1 The blanking clearance affects the section quality, dimensional accuracy, blanking force, and die life. Deformations such as fan-shaped or arc-shaped profiles are primarily related to the blanking force. The influence of blanking clearance on the blanking force follows this rule: the smaller the clearance, the greater the proportion of compressive stress in the deformation zone and the smaller the proportion of tensile stress. This increases the material's deformation resistance, resulting in a higher blanking force. Conversely, a larger clearance increases the proportion of tensile stress in the deformation zone, reduces the deformation resistance, and thus lowers the blanking force.

2-2 When the punch descends and contacts the sheet metal, the sheet is subjected to forces from the end faces of the punch and die. Due to the clearance between the punch and die, the forces they apply to the sheet create a moment M. The value of M equals the product of the resultant force from the punch and die and a moment arm 'a that is slightly larger than the clearance value.

2-3 During blanking without a blank holder pressing the material, the stage causes the material to bend. Consequently, the die and sheet material maintain contact only within a narrow area near the cutting edges. Furthermore, the vertical pressure exerted by the punch and die on the sheet is unevenly distributed, increasing sharply as it approaches the die's cutting edges.

2-4 When a stripper plate is used to clamp the material, the stress state of the material changes accordingly, which alleviates the occurrence of warping deformation to some extent. Therefore, during blanking, firmly clamping and holding the material is crucial for preventing warping in the stamped part.

2-5 During stamping, the stripper plate should move smoothly while effectively clamping the material. For key forming areas, the stripper plate can be designed with an insert-block structure. This facilitates addressing wear on the clamping areas of the stripper plate caused by long-term stamping operations, which could otherwise lead to failure in clamping the material securely.

Cause Analysis

3-1 Non-uniform Material Thickness

Non-uniform material thickness is one of the main causes of warping and twisting in stamped parts. During the production process, some areas of the material may become overstretched while others are overcompressed, leading to variations in thickness. These areas with inconsistent thickness are more susceptible to stresses, which can result in warping and twisting.

3-2 Improper Die Design

Improper die design is another cause of warping and twisting. In stamping operations, die design is a critical factor determining processing quality. An unreasonable design can lead to uneven stretching and excessive compression of the material, thereby causing warping and twisting.

3-3 Differences in Material Properties

Differences in material properties are also a key factor contributing to warping and twisting. Material properties include factors such as hardness, ductility, and toughness, all of which influence the material's behavior during processing. If there are significant differences in the properties between different materials, even when using the same die, the resulting stamped parts are likely to exhibit issues such as warping and twisting.

3. Exploration of Methods for Material Flipping and Distortion in Progressive Die Stamping

Mold Design and Preparation

During the mold design and preparation phase, the following points should be noted to prevent material twisting and distortion:

1. Design the mold appropriately to avoid excessive stretching or compression of the sheet metal.

2. Select appropriate tooling, including elbows and sliders.

3. Flatten and hammer the stretched or bent sheet metal.

4. Control the use, direction, and intensity of the coolant spray.

Production Stage

During the stamping production process, the following points should be noted to prevent the occurrence of warping and twisting:

Control the settings of the machine tool and the automatic feed rate.

Determine the pressing position and the range of penetration depth.

Install plastic support pads at the bottom to reduce deformation beneath the sheet.

Apply relatively lower die pressure.

Avoid subsequent drawing processes on the stamped parts.

Inspection Stage

After the stamping process is completed, the following procedures are necessary to ensure the quality of the stamped parts:

Use a press to firmly secure the part at the specific coordinates to be measured, confirming whether the part's shape is consistent.

Inspect the stamped part by observing whether any warping is present on its surface.

Use a measuring instrument to check for variations in thickness at different coordinates, determining whether the material thickness of the stamped part is uniform.

4. The Conclusion of Warping and Twisting

Warping and twisting are common issues in stamping processing, but their occurrence can be suppressed through the methods described above. During the initial die design and preparation stages, the principles outlined should be followed when selecting dies, tools, and performing pre-processing steps for the sheet metal. Materials with different properties need to be processed separately. During the production and inspection stages, the processing methods should be continuously optimized, utilizing appropriate tools to inspect the stamped parts and making timely adjustments. The aforementioned methods can minimize the occurrence of warping and twisting as much as possible, thereby enhancing the quality of the stamped parts.

ZHUHAI GREE DAIKIN PRECISION MOLD CO., LTD.